I learned quite a bit about Shimano Di2 when I installed one of the first available Time Trial/Triathlon groupsets on my Cervelo P2. I’ve subsequently answered a lot of questions on forums and article comments, and elsewhere. In doing so, I realized that people have a lot of questions about Di2 and the answers are difficult to find. This lead me to create this article, to consolidate everything I know and have been asked into one location so people can find answers. If you can’t find what you’re looking for below, please leave a comment and I’ll do my best to help.

I learned quite a bit about Shimano Di2 when I installed one of the first available Time Trial/Triathlon groupsets on my Cervelo P2. I’ve subsequently answered a lot of questions on forums and article comments, and elsewhere. In doing so, I realized that people have a lot of questions about Di2 and the answers are difficult to find. This lead me to create this article, to consolidate everything I know and have been asked into one location so people can find answers. If you can’t find what you’re looking for below, please leave a comment and I’ll do my best to help.

Index: There’s lots of info in this post, so here’s an Index to help you find specific sections:

- Di2 General Overview

- Compatibility: Between 6770 10-speed, 6780 11-speed, 9070 11-speed, first-gen 7970

- How to Check Battery Level

- How to Adjust Rear Derailleur Trim

- How to Adjust Front Derailleur Trim

- Dealer Installation Manuals

- Shimano E-tube Project Software – Change Settings and Update Firmware

- Chargers, PC USB Interfaces/Programmers

- Component Overviews

- Shift/Brake Levers

- Dedicated Shift Buttons

- Front Derailleurs

- Rear Derailleurs

- Display Units and ANT Bluetooth Wireless Communication Modules

- Batteries and Battery Mounts (Internal and External)

- Front Cable Connection A Junctions (with charger ports and LED status lights)

- Rear Cable Connect B Junctions

- Cables, Grommets, Cable Install Tools

- List of Components Needed to Build Your Own Di2 System

- Technical Details of the Di2 CANBUS protocol and signaling

System Overview: Shimano Di2 Dura-Ace 9150 and 9070 and Ultegra 6770 and 6870

The second generation Shimano Ultegra 6770/6870 and Dura-Ace 9070 “E-Tube” electronic bicycle shifting systems consist of battery-powered electric derailleurs activated by handlebar mounted push buttons. Power and shift commands are sent via a 2-wire CAN (Controller Area Network) datalink contained within a single cable housing. This design has several advantages over conventional mechanical shifting systems, the most notable of which are:

- Extremely low shifting effort, which generally results in more frequent shifts and therefore better gear ratio selection.

- Greatly improved shift quality, especially for the front derailleur chainrings, allowing shifting under full power with almost no chance of a dropped chain.

- Shifting is available at multiple positions on the handlebars, for example, at the end of the time trial aero bars, on the brake levers, up to in climbing position, and down low the sprint position.

- Automatic trimming of the front derailleur position as the rear derailleur moves back and forth between the smaller and bigger gears. This eliminates unintended contact (and noise) between the front derailleur and the chain.

- Lighter weight vs. equivalent mechanical system. The Shimano Dura-Ace Di2 9070 electronic groupset with internal battery weighs 2047 grams; the Shimano Dura-Ace 9000 mechanical groupset weighs 2074 grams (27 grams more than Di2.)

- Multi-Shift: Pressing and holding a rear derailleur shift button results in shifts through multiple gears. The rate of shifts can be configured using the PC computer interface cable and the free Shimano E-tube Project software.

- Synchronized Shifting: Starting with Dura-Ace 9150, automated Synchronized Sifting of the front derailleur is an option. Two SHIMANO Synchronized Shift modes will be available:

- Full SHIMANO Synchronized Shift: the front derailleur reacts based on the rear derailleur’s shift action. This essentially means that, when activated, there is no need for two separate shifters to control front and rear derailleurs, the two buttons on one shifter will control both derailleurs.

- Semi SHIMANO Synchronized Shift mode: the rear derailleur reacts based on the front derailleur’s shift action, shifting to the next most appropriate rear gear when the rider makes a front shift.

- R9120, R9170 – syncroshift enabled with firmware 3.2.0 or newer

- 6870, 9070 – syncroshift enabled with firmware 3.2.1 or newer

- 6770 – no syncroshift firmware update will be offered

Historic Info on the older first generation 5-wire Shimano Dura-Ace Di2 DA-7970 system and how it compares to the new E-tube 2-wire system:

Historic Info on the older first generation 5-wire Shimano Dura-Ace Di2 DA-7970 system and how it compares to the new E-tube 2-wire system:

Released in 2009, the 7970 operated using a very basic 5-wire electronic system. Each shift button was connected to a different wire; shorting the specific wires together controlled the derailleur upshifts and downshifts. Because the first generation 7970 used completely different technologies than the newer 2-wire systems, none of the components are cross-compatible. At this point, Shimano is not expected to offer any updates or new components using the first generation 7970 architecture; everything from now on will be based on the newer 2-wire E-tube design. The second generation design offers several advantages, which include: 1) smaller wire size, smaller connector size, waterproof connectors; 2) all switches can be reconfigured in software to send upshift or downshift commands to either the front or rear derailleur; 3) firmware updates can add new features (such as multi-shift) and compatibility with new components.

Compatibility: Dura-Ace 9070 and Ultegra 6770 / 6870 (and old 5-conducter 7970)

The confusing naming system used by Shimano makes it difficult to figure out what each component is, much less what is compatible between systems. Here are some compatibility guidelines:

- Nothing from the first generation (4-conductor / 5-conductor) Dura-Ace Di2 7970 system is compatible with any other newer system. It was replaced by the (2-conductor) E-tube systems. No parts are inter-operable between 7970 and any other Di2 System.

- In general, every electronic Di2 component is compatible between the Ultegra 6770, 6870, and Dura-Ace 9070 systems (see exceptions below.) This means that all of the road bike Ultegra/Dura-Ace dual control brake levers/shifts, time trial shifters, and climbing shifters can be used with either Ultegra 6770/6870 or Dura-Ace 9070 front and rear derailleurs. Any of the Ultegra/Dura-Ace controllers (A Junctions) can be used with either system. All components use the same cables and connectors.

- Firmware Update Required to Make Older Components Compatible with Newer Components: If you add a new component and it doesn’t work, update the firmware using the PC USB adapter and the Shimano E-tube Project Software for Windows.

- Synchronized Shifting and Bluetooth Wireless Units can be added to all E-tube Ultegra and Dura-Ace systems but the battery has to be upgraded to the BT-DN110 Internal Battery or BM-DN100 External Battery Mount. To add Bluetooth capability, a EW-WU101 or EW-WU111 inline transmitter must be added to road bikes and for mountain bikes, the SC-MT800 or SC-M9051 display/transmitter unit must be added.

- Compatibility Exceptions:

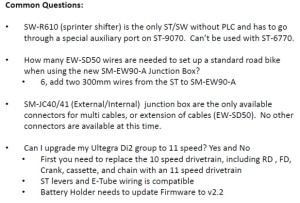

- Note 1 – Sprint Shifter Exception: The Sprint Shifter is the only exception for shifter incompatibility. It has a different wiring connector (and internal components) that can only plug into a unique/dedicated third port on the Dura-Ace ST-9070 Dual Control Brake Levers/Shifters and also the ST-6870 Levers. There is no sprint shifter port on the ST-R785 Hydraulic Levers.

- Note 2 – Can’t mix 10-speed/11-speed front/rear Derailleurs: It is no longer possible to use a 10-speed front derailleur with an 11-speed rear derailleur (and 11-speed front with 10-speed rear.) See note farther below to read the history on this if you want all the messy details.

- Note 3 – Front A junction and Internal Battery: Since the February 2015 firmware update, the older SM-EW67-A-E Front Junction A is no longer compatible with the BTR2 Internal Battery because it does not have the charging port to charge the internal battery. The SM-EW90 Front Junction (with integrated charging port) should be used instead. The SM-EW67 still works with the external battery.

- Note 4 – Update the Firmware to make components compatible: If the firmware on all components is not updated to the latest version, some components may be not operate correctly with one another. So download the latest E-tube software and update everything and it should work.

- Note 5 – All Shifters work with all 10-speed and/or 11-speed Rear Derailleurs: All of the shifters are compatible with either the 10-speed Ultegra 6770 or 11-speed Ultegra 6870/Dura-Ace 9070 systems as long as they all have the latest firmware. The rear derailleur is the only component that “knows” or “cares” how many rear gears are available. The shifters only send upshift/downshift commands and do not “know” or “care” which gear is currently selected and how many total gears there are.

- Note 6 – SM-BTR1 External Battery and SM-BMR1 Mount firmware updates: The more expensive dedicate service tool (SM-PCE1 PC Interface) must be used to upgrade the firmware on the external battery/mount.The external battery and battery mount can not receive firmware upgrades via the SM-EW90 Front Junction A and the SM-BCR2 PC Interface/Battery Charger. (The SM-EW90 will work in a system with an external battery, but a firmware update can cause them to become incompatible until both are updated independently using the appropriate PC Interface and the Shimano E-Tube Project software.)

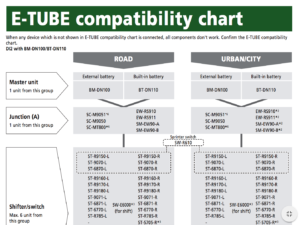

- See the Shimano E-tube compatibility chart version 3.4.3 for more details

Compatibility: 11-Speed Rear Derailleur and 10-speed sprockets/wheels

The 11-speed Dura-Ace 9070 and Ultegra 6870 rear derailleurs are designed exclusively for 11-speed rear sprockets and 11-speed Front Derailleurs. Shimano does not provide a way to recalibrate/reprogram them for a 10-speed setup. The sprocket spacing is slightly smaller and the overall range of travel slightly longer on 11-speed systems. If you have 10-speed wheels and 10-speed sprockets, you should use the 10-speed RD-6770 rear derailleur and a 10-speed FD-6770 front derailleur.

Similarly, a 10-speed RD-6770 rear derailleur should not be used with 11-speed sprockets. There will be chatter in some gears, and there might be slow-shifts or self-shifts.

It doesn’t matter which shifters are used; the shifters send upshift/downshift commands regardless of which derailleur config is being used. Shifters do not “know” or “care” which gear is currently selected and how many total gears there are.

Front Chain Rings: In general, most any front chain rings will work, rigid forged rings work best with Di2 due to high front derailleur shift forces. Shimano chain rings tend to be the best, but most others work as well. A 10-speed specific or 11-speed specific chain should be used, but the differences between them are minimal and can generally be mixed/matched without issue.

How to convert “non-upgradeable 10-speed only” wheels such as Zipp 900/Sub9 Disc Wheels to 11-speed: “the spacing between a Campy 11 and Shimano 11 is close enough that you can use the cassettes interchangeably. If you get a Campy free hub body, the 2 shims (part# is on the Zipp website, just search for Campagnolo 11) and a Campy cassette and you’re ready to ride with all 11 cogs available to use.” via slowtwitch.com

But it’s an emergency and I need to use a 10-speed wheel. . . In emergency situations, 11-speed rear derailleurs can be used with 10-speed sprockets. There will probably be chatter in some gears, and there might be slow-shifts or self-shifts. To setup an 11-speed rear derailleur for a 10-speed sprocket setup, adjust the mechanical limit screw so that it can’t shift into the missing 11th sprocket position, then follow the rear derailleur adjustment procedures listed below.

Included for very motivated individuals only: 10-speed front derailleurs can be used with 11-speed rear derailleurs if the shifters and battery have firmware installed from E-tube software version 2.5.2 or earlier. Shimano disabled support for this 11-speed and 10-speed cross-matching with later firmware updates. For informational purposes only, the details of how to regain compatibility are detailed below.

- Important Notice 2014-07-14: There is a compatibility issue with Shimano e-Tube software/firmware versions v2.6.0 and later that prevents 10-speed front derailleurs (FD-6770) from working with 11-speed rear derailleurs (RD-6870) and 11-speed front derailleurs (FD-6870) from working with 10-speed rear derailleurs (RD-6770). DO NOT UPDATE FIRMWARE using Shimano e-Tube software v2.6.0 or later if you are mixing an FD-6770 front derailleur and a RD-6870 11-speed rear derailleur, or a FD-6870 with a RD-6770.

- The problem component is the battery (external battery mounts SM-BMR1 and SM-BMR2, internal seat post battery SM-BTR2.) If you keep battery firmware at v2.0.6 or earlier, the system will continue to function properly. Shimano e-Tube Software v2.6.0 will update battery firmware to v3.0.5, and will not allow the RD-6870 to work with a FD-6770 setup.

- If the battery firmware is updated to 3.0.5, it CAN NOT be rewritten back to the older version. You will need to need to replace a derailleur so that both are 6770 10-speed or so that that both are 6870 11-speed. (The other option is to get get a battery with the older firmware and never update it.)

- Here’s a link to the “last known good version” of the Shimano e-Tube software to work with a mixed 10-speed/11-speed system: E-tube_Proj_V_2_5_2.zip Use this version and do not connect to the internet when using it so that E-tube can’t check for updates when open.

- To roll-back newer versions of battery and shifter firmware, install E-tube version 2.5.2 and made a copy of “C:\ProgramData\E-tube Project\FW” which has all the firmwares packaged in that version of E-tube. Next, install the latest version of E-tube. Then copy all the firmwares from the the 2.2.3 version back to the same location “C:\ProgramData\E-tube Project\FW” for the latest version (note: ProgramData is a hidden directory, click here for details on how to view it.). Next, the trick is to find the firmware you want to downgrade (pretty easy from the name and version in the file name), and then rename it to the same name as the latest version, but increment the last version digit by one. Then connect to the bike with E-tube (without an internet connection) and it will identify that a firmware upgrade is available for that component and allow you to do the firmware “upgrade” to the older version of firmware. Now exit E-tube and then rename the firmware file back to original to prevent the issue in future. E-tube will then try to upgrade again but just don’t let it do that. This should get a bike that did nothing (not even enter adjustment mode) to a fully working state by reverting the battery and shifters. Running latest firmware in derailleurs seems to be fine. (thanks to commenter vosadrain)

- It will not be possible to charge the BTR2 internal battery using the BCR2 USB charger unless you also downgrade the firmware of the BCR2 USB charger as well.

- Note however that latest E-tube software will say the setup is unsupported and will not allow programming. To do programming, disconnect the internal battery and connect a spare external battery. This allows making settings changes. To program the BTR2 itself, I just connect to the BTR2 by itself (no other components) and the E-tube software will allow firmware changes to it. Or try using the 2.5.2 version of E-tube.

- Alternatively, buy a Di2DIY internal seat post battery kit and you will not have to go through the firmware downgrading. The kit makes it possible to run all components with the latest E-tube firmware. Also worth noting some firmware updates were done to fix power distribution errors in the FPGA’s that would allow the batteries to drain down when the bike was just sitting.

Checking Battery Charge Level:

A single battery charge should give at least 1500 miles of riding. Most riders will not need to charge the battery more than twice a year.

To check the battery charge remaining, press and hold any shifting switch for 0.5 seconds or more. The amount of battery charge remaining will be indicated by the light on Front Controller A Junction.

- 100% remaining: Illuminates green (for 2 seconds)

- 50% remaining: Flashes green (5 times)

- 25% remaining: Illuminates red (for 2 seconds)

- 0% remaining: Flashes red (5 times)

When the battery charge is low, first the front derailleur will stop operating, and then the rear derailleur will stop operating. When the battery charge has been fully spent, the derailleurs will be fixed at the last gear shifting position. If the battery indicator is illuminated red, it is recommended that you recharge the battery as soon as possible.

Adjusting the Rear Derailleur Trim:

If you switch between multiple rear wheels, it’s very likely that the sprockets on different wheels won’t be in exactly the same relative position to the rear derailleur, resulting in that annoying clicking sound as the chain makes contact with an adjacent sprocket. Follow the steps below to properly align the rear derailleur with the rear sprockets.

- Shift the rear derailleur to the 5th sprocket position. Press the button at the junction (A) of the SM-EW67-A-E until the red LED illuminates in order to switch to rear derailleur adjustment mode. Note that if you keep pressing the button after the red LED has illuminated, protection recovery operation will begin.

- If shifting switch is pressed once while the initial setting condition is active, the guide pulley will move one step toward the inside. If shifting switch (Y) is pressed once, the guide pulley will move one step toward the outside.

- Note: The guide pulley can move 15 steps inward and 15 steps outward from the initial position, for a total of 31 positions.

- Note: When adjusting, the guide pulley will overrun slightly and then move back in an exaggerated movement so that you can check the adjustment direction. When checking the positions of the guide pulley and the sprocket, check at the position where the guide pulley finally stops.

- While turning the front chainwheel, operate shifting switch to move the guide pulley toward the inside until the chain touches the 4th sprocket and makes a slight noise.

- Next, operate shifting switch 4 times to move the guide pulley toward the outside by 4 steps to the target position.

- Press the button at junction (A) until the red LED turns off in order to switch from rear derailleur adjustment mode to gear shifting mode. Shift to each gear and check that no noise is generated at any gear position. If fine adjustment is needed, switch back to adjustment mode and readjust the rear derailleur.

- Note: if you have customized your shifters and swapped buttons, this will change which shifter and buttons control the micro-adjustments. Also, if you hit the wrong buttons while trying to set the FD trim, you can actually alter the setup of your RD. Be certain that you’re hitting the correct adjustment buttons.

- If you have a Garmin or similar head unit and a SM-EWW01 ANT module, the display will automatically switch into derailleur trim display when you activate that mode (i.e. by pressing the button at the junction (A) of the SM-EW67-A-E.) It will give you the trim position in either + or – 12 positions. When switching wheels, simply take note which position suits which wheel/sprocket/trainer, and trim to that level each time you change. This removes the guesswork and makes changing from wheel to trainer simple.

Note on FD-6870 Front Derailleur Trim:

The FD-6870 trim adjustment effects the auto-trim positions. The adjustment feature is accessible via either the A-Junction box, or the “Front derailleur adjustment setting” in the e-tube software, and should be used only after you have already set the physical inner/outer limit screws. So for example, if the FD outer plate rubs the chain when using the 6th largest cog, you would want to adjust the FD trim outward a couple ticks. However, you can only perform this adjustment while in the big-ring/big-cog combination. Etube forces the derailleurs into this maximum cross-chained position, whereas during the manual method you must shift to these positions yourself. (Thanks to commenter Bryan B for the info.)

Dealer Manuals:

The dealer’s manuals contain the most detailed information available from Shimano. If you’re looking for detailed installation instructions, check here:

- Shimano Ultegra 6770 Dealer’s Manual: http://techdocs.shimano.com/media/techdocs/content/cycle/SI/Ultegra/UltegraDi2/6770Di2_DM_EN_v1_m56577569830773882.pdf

- Shimano Ultegra 6870 Dealer’s Manual: http://si.shimano.com/php/download.php?file=pdf/dm/DM-UL0001-00-ENG.pdf

- Shimano Dura-Ace 9070 Dealer’s Manual: http://si.shimano.com/pdf/dm/DM-DA0001-00-ENG.pdf

- Shimano Alfine Di2: http://si.shimano.com/php/download.php?file=pdf/dm/DM-AL0001-03-ENG.pdf

Shimano E-tube Project Configuration and Firmware Update Software for Windows:

Shimano E-tube Project Wireless for iOS and Android: Announced on April 15, 2016 but as of yet unreleased, these apps will allow configuration of shift profiles (multi-shift on/off, multi-shift delay between shifts, shifter button assignments) and firmware updates over Bluetooth. To function, a Shimano Di2 Bluetooth Adapter, such as the MT800 digital display, is required.

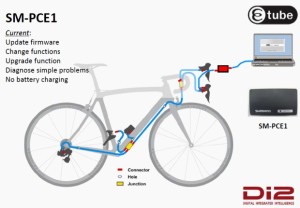

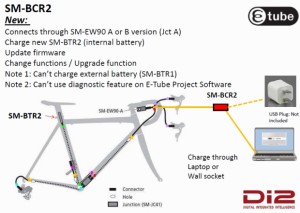

Shimano E-tube Project Windows PC Software: This free software is used to update the firmware of all components. It works with the SM-BCR2 Charger + USB Adapter and the SM-PCE1 Diagnostic Adapter. The software is used to change the configuration of each shift button / lever (any can be programmed to upshift or downshift either the front or the rear derailleur.) It can also be used to enable multi-shift (multi-shift is where the shifter is held and the rear derailleur shifts through multiple gears until the shifter is released.) The delay between of the gear changes during multi-shifting can also be adjusted. The software is available from http://e-tubeproject.shimano.com/

Older versions of the e-tube software are available from these links: 2.5.2

PC & Mobile Interfaces, Chargers, and Software:

SM-BCR1 Battery Charger: This is used to charge the external battery. The part number for the battery charger wall cord is SM-BCC1.

SM-BCR2 Charging and PC Connection: for SM-EW90-A 3-port and SM-EW90-B 5-port A Junctions. This plugs into a special port on the side of the A junctions (which is covered by a rubber flap.) This adapter charges the internal battery when first plugged into the A junction; it must be powered by a standard USB Wall charger (such as that used for an Apple iPhone) or a PC that is powered-on. If the Shimano E-Tube Project Software is launched on the Windows PC with the SM-BCR2 attached, the SM-BCR2 will switch from charging mode to configuration mode. It must be detached from the computer and reattached to switch back to charging mode.

- It takes about 2 hours to charge the internal battery.

- Amber light=charging.

- Light turns off when done.

- If the Amber light does not come on when plugged in, this indicates battery is not discharged enough to charge.

- Light flashing indicates something is wrong, like trying to charge a external battery through a BMR.

Hacking the SM-BCR2 to have a standard Di2 cable connector: If your 3-port or 5-port junction is inaccessible for charging, there is an alternative hack method to connect it to the system through a standard Di2 port. With basic soldering skills you can hack the BCR2 to be used with any setup. Buy any length EW-SD50 wire, cut off one end. Cut the wire on the output side of the BCR2. Splice the two wires together, so that the output wire of the BCR2 is now a standard Di2 connector. The charger has an inner (white) and outer (shield) wire; connect the inner white wire to the SD50 red wire; connect the charger outer shield wire to the SD50 black wire. You will then be able to plug the BCR2 into any Di2 port. Or use a SM-JC40 junction B and another length of EW-SD50 wire and go through the RD (by using the SM-JC40 to connect the rear derailleur, new output wire of the EW-SD50, and the wire that ordinarily connect the rest of the system to the rear derailleur.) Thanks to @Di2diy for the info.

SM-PCE1: This PC Configuration and Diagnostics adapter will not charge the internal battery. It offers the same configuration options as the SM-BCR2, but also add some advanced diagnostic and troubleshooting features that the SM-BCR2 does not have. It attaches to via the standard E-tube wire (just like the EW-SD50 cables) rather than to a dedicated port on the side of the front A junction.

Bluetooth and E-tube Apps for Apple iOS and Android: Bluetooth wireless modules are available to allow system settings to be adjusted via the mobile applications that connect via Bluetooth Adapters.

Component Overview:

The confusing naming system used by Shimano makes it difficult to figure out what each component is, much less what it does and how it fits into an a complete Di2 system. Here’s an overview of all the major Ultegra and Dura-Ace Di2 components.

Dual Control Brake Levers/Shifters (a.k.a. Brifters):

ST-6770 Ultegra Road Dual Control Brake Levers/Shifters: The Ultegra version can be used with the climbing shifters. They are sold in in left/right pairs and are also available separately.

ST-9070 Dura-Ace Road Dual Control Brake Levers/Shifters: The main advantages these have over the ST-6770 version is slightly lighter weight and compatibility with the low-mount sprint shifters. As like the Ultegra version, they are compatible with the climbing shifters. They also have hidden button under the rubber hoods that can activate screen changes on cycling computers from Garmin, Magellan, Pioneer, and Shimano (Shimano SM-EWW01 ANT Wireless Broadcast Module required.)

ST-9071 Dura-Ace Time Trial/Triathlon Dual Control Brake Levers/Shifters: These levers provide shifting from the pursuit bar position on time trial bikes. There is no Ultegra option offered at this time. These are available as left/right pairs, or can be ordered separately. These do have a permanently attached wire with a male end for connection the the SM-EW90 front “A” junction. Combined weight both levers: 117 grams.

ST-R9160 (standard cable brakes) and ST-R9180 (hydraulic brakes) Time Trial Dual Control Brake Levels/Shifters: These are the lower-profile shifters offered with the newer Dura-Ace R9150 groupset.

ST-6871 Ultegra Time Trial/Triathlon Dual Control Brake Levers/Shifters: Ultegra version of the ST-9071 Dura-Ace shifters. Slightly heavier and much less expensive than the Dura-Ace version. Combined weight both levers: 142 grams.

ST-R785 Hydraulic Road Dual Control Brake Levers/Shifters: These hydraulic road shifters are compatible with both the climbing and sprint shifters. These are compatible with the SM-RT99 centerlock 140mm and 160mm rotors and WH-RX31 wheelset (which as no standard rim brake track.) These require the BR-785 dual piston hydraulic disc calipers. They do not have the special wiring port required for the SW-R610 Sprint Shifters and a SM-EW90-B 5-port junction A is required to use the SW-R600 climbing shifter.

ST-6870 Ultegra Road Dual Control Brake Levers/Shifters: These road shifters are compatible with both the climbing and sprint shifters.

Dedicated Shifters:

SW-R671 Dura-Ace 2-Button Time Trial/Triathlon Bar End Shifters: These shifters are installed on the end of time trial aero bars. By default, the left shifter upshifts/downshifts the front derailleur; the right controls the rear derailleur. For both, the lower button upshifts into a harder gear and the upper button downshifts to an easier gear. This can be changed using the Shimano E-tube Project software; the functions of the left and right sifters can be switched with one another as well. These are available in pairs or separately.

SW-9071 Dura-Ace 1-Button Time Trial/Triathlon Bar End Shifters: These shifters have only one button each and are intended to control only the rear derailleur, with one sending the upshift command and the other the downshift command. (I personally think this version is absolutely worthless. Why have 2 SW-9071 shifters at twice the price and twice the weight, when you can just buy a single SW-R671 Right shifter instead.)

SW-R600 Climbing/PAVE Shifter: This shifter is for road bikes and is mounted on the upper horizontal portion of the handlebar, or any other location comfortable for the rider. They can be used in addition to the Dual Control Brake Lever/Shifter, or can be used on their own by plugging directly into a SM-EW90-A 3-Port Junction or SM-EW90-B Dura-Ace 5-Port Junction.

SW-R610 Dura-Ace Sprint Shifter: This is the only component using a unique wiring connector; it is only compatible with the ST-9070 Dura-Ace and Ultegra ST-6870 Road Dual Control Brake Levers/Shifters. Unlike all of the other shifters, the sprint shifters do not contain a circuit board; they do not show up as components on the CAN bus network. Instead, the sprint shifters are simple momentary switches that activate the circuit board on the host Dual Control Brake Lever/Shifter. The host dual control lever is what sends the shift command. (Note: Any momentary switch can be attached to the sprint shifter port on the Dual Control Levers by splicing into a standard EW-SD50 wire to act as remote shifters.)

Alfine SW-S705 Right Flat-Bar Shifter: Reported to work with other non-Alfine setups.

SW-R9160 Time Trial bar-end shifters (pair): These are-end shifters directly control the rear derailleur, with one for the upshfit and one for the downshift. The front derailleur is controlled automatically via automatic Synchronized Shifting. These shifters require the BT-DN110 Internal Battery for synchronized shifting.

SW-R9150 Climbing shifters (pair): These tiny climbing shifters are about as small as the sprint shifters, but can be directly connected to a junction box and do not have to be connected as slave buttons to a brake/shift lever special port. They come with plastic mounts to make it easier to attach to bars beneath bar tape. They are ideal for synchronized shifting, with one controlling the upshifts and the other downshifts. These shifters require the BT-DN110 Internal Battery for synchronized shifting.

Front Derailleurs:

FD-6770: Ultegra Front Derailleur

FD-6870: Ultegra Front Derailleur, pretty much identical to the FD-6770 but with a slightly larger diameter adjusting screw (to better dissipate the shifting forces).

FD-9070: Dura-Ace Front Derailleur

FD-R9150: Dura-Ace Front Derailleur for 9150 systems; features slightly reduced weight vs. 9070.

Rear Derailleurs:

RD-6770: Ultegra 10-Speed Rear Derailleur, compatible with gears up to 28 teeth.

RD-6870: Ultegra 11-Speed Rear Derailleur, compatible with gears up to 32 teeth (for the GS version).

RD-9070: Dura-Ace 11-Speed Rear Derailleur, lighter weight version on which the RD-6870 is based.

RD-R9150: Dura-Ace 11-Speed Rear Derailleur with 30-tooth sprocket compatibility and modified “Shadow RD” geometry to keep the mechanism close to the rear wheel to help avoid damage in the event of an accident.

Alfine SG-S505 and SG-S705: The Shimano series targets comfort and urban bikes. It uses an 8-speed (505) or 11-speed (705) internal epicyclic rear hub. It is believed to be compatible with other Di2 ETube components but this has not been verified.

Display / Wireless Communication:

SM-EWW01 ANT Wireless Broadcast Module: This module wirelessly broadcasts Di2 data (front and rear gear selection details, gear ratio, battery life) to a cycling computer using the ANT protocol. It is compatible with Dura-Ace 9070, Ultegra 6870 Di2 and Ultegra 6770 E-tube road shifting systems. SM-EWW01 plugs into the E-tube wiring system between existing components. It has an 2 wiring ports, so it can be connected between a front shifter and the Front Junction A, or at the rear derailleur (between rear derailleur and Etube wire.) It transmits through a proprietary private ANT wireless protocol, which may eventually become a standard public ANT+ protocol. It is powered by the same Di2 system battery. It is currently compatible with the Garmin Edge 1000, Mio 505, and the PRO SCIO cycling computers (with more to come.) The hidden buttons under the hoods of the 9070 shifter levers will switch screens on the cycling computer when paired with this module. It does not currently allow for shifting control from a cycling computer/device and it is not clear that this functionality will ever be offered. The SM-EWW01 is 38mm long, 25mm wide, 12.5mm high, and weighs less than 5 grams. It does not come with any wires; 1 wire would have to be added if adding this module to an existing Di2 system.

EW-WU101 and EW-WU111 ANT and Bluetooth Wireless Broadcast Modules: These modules are similar to the SM-WEE01 but also include Bluetooth capabilities in addition to ANT capabilities. They require the BT-DN110 battery or the BM-DN100 Battery Mount and cannot be used with the SM-EW67 Front A Junction.

SC705 Alfine Display Unit: This unit displays the battery level and the rear derailleur gear selection. It is powered by the system battery and has a port for the SM-BCR2 internal battery charger / USB diagnostic tool. It is primarily designed for Alfine systems (both 8 505-series and 11 speed 705-series). It is compatible with Ultegra and Dura-Ace Di2.

MT800 Digital Display with Bluetooth: Primarily aimed at XT mountain bike applications, this display allows toggling between the 3 synchronized shift modes (where both derailleurs are intelligently coordinated in unison by one pair of buttons, so no need for discrete shifting of the front derailleur.) It also shows battery level, gear position, shift mode and FOX iRD suspension position. The Digital Display required the new BT-DN110 battery. Existing Di2 XT systems are upgradable to be compatible with the new digital display after battery upgrade and firmware upgrade. This display has 3-port Di2 Cable junction and charging port integrated into the back and serves as a Front A Junction.

Batteries and Battery Mounts:

The batteries contain the main controllers for the system. It is therefore required to upgrade the battery to get features released in new versions of Di2 (such as Synchronized Shifting that automatically controls the front derailleur based on rear derailleur shifting.)

SM-BTR1 External Battery: This external battery must be used with the SM-BMR1 battery mount. It is removed from the mount and charged using a dedicated charger.

SM-BMR1 and SM-BMR2 External Battery Mount: This mount attached to bottle cage mount points or other dedicated frame mounts. It is available in 3 different mount lengths: -I (intermediate length), -S (short length), -L (long length). The SM-BMR2 is an updated version of the SM-BMR1.

SM-BTR2 Internal Battery: This battery is typically mounted in the seat post or seat tube of the frame. It is charged by plugging the SM-BCR2 Charging Cable/PC Adapter into the SM-EW90-A or SM-EW90-B Front A junctions.

BT-DN110 Internal Battery: This battery is required for Bluetooth wireless units and road groupset Synchronized Shifting functionality.

BM-DN100 External Battery Mount: This battery is required for Bluetooth wireless units and road groupset Synchronized Shifting functionality.

Front A Junctions:

SM-EW67-A-E Ultegra 3-Cable Junction: This is the original front junction with 2 integrated cables to connect to the dual control brake lever/shifters. The male cable ends on this Front A Junction will not mate directly to the male cable ends on any of the Time Trial/Triathlon dual control brake shift levers or shifters; SM-JC41 Rear B Junctions can be used to connect this front A junction to TT/Triathlon shifters. This Junction works only with External Batteries, not Internal Batteries.

SM-EW90-A Dura-Ace 3-Port Junction: This front “A” junction is most commonly used in road bike setups. 2 ports connect to the dual control brake / shift levers; the third port is for the cable that leads to the bottom bracket junction.

SM-EW90-B Dura-Ace 5-Port Junction: This front “A” junction is primarily used in the Time Trial / Triathlon setups. 2 of the port are for the brake/shifter dual control levers, 2 of the ports are for the aer0 bar bar-end shifters, and the 5th port is for the cable that runs to the bottom bracket (where the B junction joins the wires from the front A junction, front derailleur, rear derailleur, and battery.)

EW-RS910 Internal Bar-end Junction: This junction is installed into the end of a bar or in a dedicated frame port. It facilitates internal cable routing.

B Junctions:

SM-JC41 Internal Junction: This version has the exact functionality as the SM-JC40 external version, but doesn’t have the mounting tab for being bolted to the bottom bracket or wrapping the extra cable lengths. It has 2 ports on one end and 2 on the other, making it more compact. In addition to being located at the bottom bracket to connect the A junction, battery, front derailleur, and rear derailleur, it can be used at the handle bars to join multiple shifters prior to being connected to the A Junction.

SM-JC40 External Junction: This version is intended to be attached to the frame using the bolt that is commonly located underneath the bottom bracket housing. This junction contains no electronics; it’s sole purpose is to join 4 connectors together, which are usually the wire from the front A junction, the battery, the front derailleur, and the rear derailleur. There are wire holders above the housing to capture the extra wire length by wrapping it back-and-forth.

Cables, Grommets, and Cable Remove/Install Tool:

EW-SD50 Cables: These cables connect the front A junction, the battery, the front derailleur, and the rear derailleur to the rear B junction, which is typically located near the bottom bracket (near the cranks.) These are available in lengths of 300mm, 350mm, 400mm, 500mm, 550mm, 600mm, 700mm, 750mm, 950mm, 1000mm, 1200mm, 1400mm.

SM-GM01 Grommet: These round grommets are used when drilling round holes for internal cable routing, or with existing round holes. The required hole diameter is 6mm (6mm = .236 inches. Use a 7/32-inch drill bit and then “wallow-out” the hole to make it a little bigger; a 1/4-inch drill bit will work but is just slightly larger than necessary.)

SM-GM02 Grommet: These 7mm x 8mm oval shape grommets are used in some situations / frame designs.

Shimano TL-EW02 Ultegra DI2 E-Tube Tool: This tool is used to connect and disconnect the Etube wires. They are extremely difficult to connect/disconnect by hand, and pliers or other tools can damage the wires. Don’t get this confused with the TL-EW01 tool, which is for the older 5-wire 7970 cables. (My Dura-Ace TT Dual Control Levers came with one of these tools, but no other components did.)

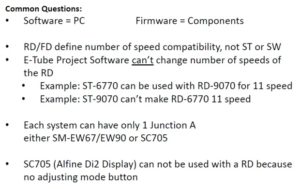

Common Questions (via Shimano):

Note: it is not necessary to replace the FD from upgrading from 10-speed to 11-speed.

What Components do I need to put together my own Di2 system?

Because of the huge number and variety of components, it’s very difficult to figure out what is actually necessary and what is optional. So here is a list, for the setup I recommend: Ultegra 6870. It starts from the handlebars and works backwards. (This assumes both front and rear derailleurs, but you actually don’t have to have both; you can pick one or the other and only the corresponding front shifter to go along with it.)

- Any Type of Shifters / Shift Buttons. The Dual Control Brake Levers/Shifters are not required. You can get the just the climbing shifters or Triathlon/TT bar-end shifters, and then potentially add the Dual Control Levers/Shifters at a later point. (The only exception is the Sprint shifters, which require specific Dual Control Levers/Shifters with special ports as noted elsewhere in this article.) Amazon.com link

- EW-SD50 Wires 1 and 2 between the front shifters and the Front Junction A (0nly for some shifters). This is a bit confusing, because some of the front shifters come with wiring attached to them and some of them require purchasing separate wires. In general, most of the stand-alone shifters come with wiring, as do the TT/Triathlon dual control shifters/levers, but the road dual control levers do not. Amazon.com link

- Front Junction A. I recommend the SM-EW90-B 5-port front junction A as it provides the most upgrade flexibility; get the 3-port option only if you’re positive you’re never going to add more shifting components. The older SM-EW67-A-E has 2 wires built-in to connect with each of the dual control shift/brake levers; it doesn’t offer much flexibility or compatibility with a TT/Triathlon setup or adding additional shifters. Amazon.com link

- EW-SD50 Wire 3 between the Front Junction A and the 4-port Rear Junction B connector. Amazon.com link

- EW-SD50 Wire 4 between the Rear Junction B and the Front Derailleur. Amazon.com link

- EW-SD50 Wire 5 between the Rear Junction B and the Battery. Amazon.com link

- EW-SD50 Wire 6 between the Rear Junction B and the Rear Derailleur. Amazon.com link

- Rear Junction B: This is where the wire from the front of the bike is connected to 3 output wires leading to the front derailleur, rear derailleur, and battery. SM-JC40 is for external wiring, SM-JC41 is for internal. Amazon.com link

- Grommets for any place where the wire goes into the frame through a drilled hole. Amazon.com link

- Front Derailleur. I recommend the Ultegra FD-6870 for 11-speed builds or the FD-6770 for 10-speed builds. The Dura-Ace FD-9070 is pretty much identical, just slightly (41g) lighter and 11-speed only. (I do not recommend the Ultegra FD-6770 unless you have a 10-speed setup, because of firmware compatibility issues with 11-speed rear derailleurs. Also, it is an older design than the FD-6870, so it is larger and offers slightly less shifting force.) Amazon.com link

- Battery and Charger. Internal or external, depending on the build. If you have to skill/time/money-to-pay-someone to get everything internal, I highly recommend that option. The SM-BTR2 internal battery has more advanced integrated electronics and is better for firmware upgrades with the SM-BCR2 internal battery charger/PC tool. If you go with the SM-BTR1 external battery, you will need the SM-BMR1 external battery mount and SM-BCR1 external battery charger. Amazon.com link

- Rear Derailleur. I recommend the Ultegra RD-6870 for a new build if you have 11-speed compatible wheels with 11-speed sprockets, or the Ultegra RD-6770 if you have 10-speed wheels/sprockets. The system must be match front and rear derailleurs (both 6870 11-speed or both 6770 10-speed.) Amazon.com link

- TL-EW02 Etube Wire Remove/Install Tool: It takes quite a bit of force to snap the wires in/out. You may think you can get it seated properly with just your fingers, only to then have the wire come loose because it wasn’t fully seated. It’s a good idea to keep one in your saddle bag. Amazon.com link

What wire lengths do I need? This question is impossible to answer correctly, as it’s highly dependent on the frame size and configuration. What I recommend is running string between the component mounting locations to measure the lengths. Be sure to add some extra length, as I find that wires seem to come up short pretty frequently, even when “adding a little extra” to start with. Nothing is more frustrating that having a wire that is 25mm too short. I recommend ordering a few extra wires of multiple lengths and then returning the unneeded/unused wires. As noted above, the standard wire lengths are 300mm, 350mm, 400mm, 500mm, 550mm, 600mm, 700mm, 750mm, 950mm, 1000mm, 1200mm, 1400mm. Do not cut/splice these wires; the connectors on the end of the wires are very small in diameter to start with and you’ll end up with a splice that is larger and less waterproof than you started with.

Acknowledgements: Special thanks to Di2diy for his continued help in the comments. Check out his Ebay store for custom Di2 batteries, harnesses, and components.

Technical Details of the Di2 CANBUS protocol and signaling

Thanks to commenter Ghislain for the details: “I reversed engineered the signal going to the RD. Since I did not have a special tap connector, I could only look at the actual signals in open loop (RD wire disconnected) on the wire going to the RD using an oscilloscope. First, I found that shift up and down are multiplexed on the same wire. A shift down would generate a positive 100 msec clean 8 volt pulse (varies between 50 msec to 500 msec depending on how long you hold the shifter). On the same wire, a shift up would generate a series of 2 msec pulses that would last the same time of a shift down pulse. Therefore, the RD has enough intelligence to discriminate between the 2 types of pulses. When you hold the button on junction A, a 140 msec pulse is generated. But since my RD wire was disconnected, the RD would not go in adjust mode.”

Hi Carlton,

I am converting my Shiv Tri bike to Di2 and will be buying mostly Ultegra 6870 components. If I buy the SM -BCR2 charger/interface, the BT-DN110 battery and the EW – WU111 is there any need to buy the SM- PCE 1?

Can the SM – PCE 1 do anything that the above combination cannot do?

(I thought I read somewhere online that problems in getting a Garmin edge 520 and Di2 to connect were overcome only by using the SM – PCE 1)

Thanks, David

Do you know if the R671 Remote TT Shifter (two button) if compatible with EW – WU111? Can you control the Edge 520 in TT position? Thank!

Hi

could you please help on how to upgrade my dura ace 9070 through E-Tube with SM-BCR2, a W10 laptop, SM-EW90-A, it is like it is not recognized after having installed everything?

Driver missing?

Thanks

This should be a very straight forward process, but lets list the steps required.

1) From your Windows 10 laptop, browse to: http://e-tubeproject.shimano.com

2) On the top menu, click on: Download the App

3) Select the blue box: Ver.3.2.1 Download

4) The downloaded file is a ZIP file and needs to be extracted (E-tube_Proj_V_3_2_1.zip) Note: This is a 95Mb file

5) Launch the app, E-tube_Proj_V_3_2_1.exe and follow the prompts to install.

Note 1: The SM-BCR2 must be disconnected from the laptop while the installation runs.

Note 2: This app requires the .NET Framework 3.5 SP1 component from Microsoft. Highly suggest this be installed before installing the E-tube app.

6) Be sure your laptop has a connection to the Internet

7) Connect your SM-BCR2 to the EW90-A and then to the laptop USB port.

8) Launch the E-tube Project app from your desktop.

9) Select your Di2 Bike Type at the top, Road, Mountain, Urban/City

10) The app will immediately start downloading all component updates, this is normal. Don’t worry, no updates are being applied to your components yet.

11) When the MENU appears, CONNECTION CHECK should be highlighted, click on this and let the app find your components. At a minimum, your EW90-A should be visible as long as the battery is connected and has a minimal charge.

Once the Component Check is completed, you should see other options to help you with your Di2 system firmware updates and setup.

Hope this helps.

Jim

Thanks a lot Jim!

I followed your instructions and it did finally work and was recognized all the components correctly. I did update to latest firmware. all correct!

But despite having read the manual:

http://e-tubeproject.shimano.com/pdf/en/HM-R.3.2.1-00-EN.pdf

when I go to the ‘shift mode setting’, and I select shift mode 1 and 2 to ‘Semi-synchronized shift’ (what does it mean mode 1 and mode 2????btw…) and rear shift up 2 on FD shift down…all set to 2 and I do ‘Complete Setup’ button

It does not make what I want:

Semi-synchronized shift is a function that automatically shifts the rear derailleur when the front derailleur is shifted in order to obtain optimal gear transition.

How should I set it up in order I get Semi-synchronized shifting??

Thanks again for your support and regards

Jan

There are 3 Shift Modes, Normal (manual), Semi-synchronized and Synchronized.

Normal – No automatic shifting is done, you control both FD & RD changes

Semi-sync – You control the FD and the RD will automatically shifts to maintain the best gear ratios.

Synchronized – Allows shifting without duplication of gear combinations. You shift the RD as normal and the FC will automatically shift and with one control input to move the RD and optimize the shift.

This is not like an automatic transmission, it’s just optimizing your shifts for best FD / RD changes.

Within the e-Tube Project software, you can customize or select what each of the 2 modes will do. You can also customize the shifts (number of gears to automatically shift up or down). My recommendation is to accept and leave it at the defaults until you have worked with if for a while. If you have changed these settings, you can press the “Restore default values” option within the program.

To change modes, press the MODE button on your cable junction box A (I use an EW-90). To change modes, press the button twice quickly to change modes, kind of like a double mouse click on a PC. The Green and Red indicator lights will flash to indicate which Shift Mode you have selected.

One Flash = Mode 0 (normal / manual)

Two Flashes = Mode 1

Three Flashes = Mode 2

The modes will cycle through, 0, 1, 2, then back to 0.

If you have the D-Fly installed on your Di2 system, the mode can be changed with the Smartphone App.

Jim

Thanks Jim again,

I had a 200 kms sportive last weekend, la mussara in Reus Tarragona, and did not want to mess around just in case…but will definetely try it tomorrow, and let you know.

I also have the SM-EWW01 ANT Wireless Broadcast Module: so not bluetooth capable.

Regards,

Jan

Hi Jim

I did push the button twice quickly to change modes, kind of like a double mouse click on a PC and The Green and Red indicator lights did not flash to indicate which Shift Mode I have selected.

You should not do it on the e-tube software?

Thanks

Jan

In order for Synchronized Shifting to function, all components in your Di2 system must meet the compatibility requirement. Check out the latest “e-Tube Compatibility Chart” to see if you meet the requirements. This chart is available at: http://e-tubeproject.shimano.com/pdf/en/HM-CC.3.2.2-00-EN.pdf

Setting the Shift Mode via e-Tube software or the A Box button is your choice, but having the ability to change it from the A Box allows a change while on the road.

Hi Jim ,

I have just checked my Di2 DuraAce components, and I still do not know what could be:

SM-BTR2 / SM-EW90-A / RD-9070 / FD-9070 / SM-BCR2 / SM-EWW01

Despite I have all firmware updated (3.0 and above..), when I double click on the SM-EW90-A cable junction to change modes, the Green and Red indicator lights does not flash to indicate which Shift Mode I have selected….is there any incompatibility with my components? I did not see any on the “e-Tube Compatibility Chart”.

Is it possible to change Shift modes, to set the Shift Mode via e-Tube software? I can only see that you can customize the modes, but not set modes from 0 to 1 and to 2 as you very well explained.

And the last chance is to change the Shift Mode via e-Tube app, but as my wireless unit is SM-EWW01, only supports ANT+…and not bluetooth, so no chance neither!

Thanks a lot for your support!

Jan

With the component combination you provided, there is a note in the compatibility chart under “DI2 with SM-BMR1/SM-BMR2/SM-BTR2”, “Limitation of function with SM-BMR1/SM-BMR2/SM-BTR2”, “*4 Synchronized shift is available only in MTB category”. As I read the chart, you would need to upgrade the battery to the newer BT-DN110 for Synchronized Shifting to work with you components.

Oh! I am gonna need extra investment…battery, plus maybe also the my wireless unit SM-EWW01, that only supports ANT+…and after I could use this semi synchronized functionality and change the customizing from the cell phone.

One last question: in the case I upgrade to the BT-DN110 Internal Battery, is it compatible with the rest of my components? Will í be able to charge the battery as I normally do it through the SM-EW90-A Dura-Ace 3-Port Junction?

And finally, I guess I will need the Shimano TL-EW02 Ultegra DI2 E-Tube Tool for installing the whole kit, correct?

Thanks very much again for all your support,

Hi Jim ,

I finally changed the components, and I can now enjoy the 3 Shift Modes!

Thanks again for your help!

Best regards

Thanks for a great and super helpful website!

Thought I would add some findings I had with my recent Di2 build.

I had issues trying to connect my iPhone to the E-Tube iOS app. When connecting I was prompted to change the passkey, but every time I tried to enter a new passkey the app suddenly crashed.

The solution was to go to Application settings and un-check “Verify that the screen for changing the initial PassKey displays.”. After that I could successfully connect through the app.

Best,

Erik

Thanks for the info. Seems like a bug that the app doesn’t auto-detect no passkey being required. Set the the passkey using the PC app. I think it’s a good idea to prevent anyone from messing with your settings.

I’ve had to lose the app then go into my iPhone settings and disconnect the WU-111 from the phones bluetooth list. Then go back into the app and try 000000 as the passcode.

Hi Di2 experts, have I made a simple mistake… I’m currently upgrading my external Di2 to internal for a new frameset I’m buying.

So far I’ve stripped down the old bike and I’ve connected all my new Di2 parts together outside of a frame to test (basically the whole system is connected together as it would be inside a frame but is currently sat on my floor).

However, despite being a brand new battery, brand new junction boxes and brand new charger, the battery fails to charge!

When I plug the new internal battery into the system I get a red light on junction box A for 1 second and I plug the charger in, I get no lights at all, none on the charger and none on the junction box A.

The rear deraileur will move if I press the shifter buttons.

I’ve plugged in my old external battery into the system and I get a green light for one second and both derailleurs shift, however the old battery is fully charged so won’t test the charger.

I would be amazed (in a bad way) if the junction box A or charger has arrived broken when brand new and never used. I’ve noticed the internal battery has a metal tab on the outside, is this a negative terminal that needs connecting to anything? Am I doing something wrong ?

Update… I’ve tried other plug sockets and other USB leads. Even on my Garmin 520 which charges ok. The fault lies between the Di2 charger box and the new internal battery. The detailleurs are moving fine and when I press the button on junction box A even goes into adjustment mode and crash protection reset mode.

before you try and charge the battery you need to update all the the firmware including the charger. You need to plug everything together, plug the BCR2 into junction A, plug the charger into your PC than using etube project update the entire system. Pay attention the the system prompts as you may need to remove the BCR2 when if the software on your computer needs to update, and the BCR2 than the components. you cannot charge the battery with etube running… best to used a USB charger for charging.

Ive opened up E-Tube Project on my laptop and plugged in the SM-BCR2 charger (still connected to the entire groupset) into the laptops USB port. Ive clicked on road bike, then connection check and the the laptop screen says the master unit (battery) and the Junction A Unit is not detected. Going into the Preset menu, it says the unit to write to could not be recognised. How do I install the new internal battery and Junction A? Thanks

First be sure you have downloaded the latest version of etube project from Shimaino than update junction A alone, than updated the battery by itself, through junction A. Than the complete system.

DI2DIY…. I have tried only having the junction(A) plugged into the BCR2 and its the same, “unit is not recognised” and the update firmware option is greyed out.

When I start E-Tube Project a window opens saying its checking for a new version. The version I have is Ver.3.2.2

Thanks

3.2.2 is the latest ver. Don’t know what to tell you. Perhaps you can find a LBS with a PCE1 to diagnose the problem.

Ben,

My initial thought would be a firmware incompatibility with this new internal battery and your other components. What is the battery version you have, SM-BTR2 (old ver) or BT-DN110(new ver). There are some functions and components that only work with the new BT-DN110.

I’d suggest two options to start. 1) strip it down to the basics, A Box and Battery and try again. 2) Try to update the firmware. You may need to put the external battery on and upgrade all the components, then try the internal battery again.

One last thought. if you are connected to the A Box and have e-Tube running, the battery will not charge. It doesn’t sound like this is your issue, but wanted to mention in.

Cheers

Jim, I originally used the BTR-1 external battery and the groupset worked fine. Im trying to upgrade it to the internal BT-DN110-1 battery. When I go onto the road bike page of E-tube Project… the Customise, Error Check, Update Firmware buttons are all greyed out. When I click on Connection Check the SM-BCR2 connects but then E-tube Project says the Master Unit and Junction A is not recognised. Ive tried to go into the Preset menu but this eventually says the units to write to could not be recognised. Or the units to read could not be recognised. Interestingly when I start E-Tube Project a window says charging was stopped, but theres no indications the battery was even charging anyway (the original fault).

First, there is a new version of the e-Tube project, ver 3.2.2, released on May 24, 2017. I would upgrade to this version, then review the compatibility chart located at http://e-tubeproject.shimano.com/pdf/en/HM-CC.3.2.2-00-EN.pdf

Be absolutely sure your Battery type and A Junction Box are compatible with the rest of your system. Pay particular attention to the *Notes at the bottom of each battery type section. This may help lead you to resolution.

Until you successfully complete the “Connection Check” these options will be grayed out. The Master Unit is your battery.

Carlton, what a website. Good on you!

Question: I have Ultegra Di2 6870 series. I’d like to switch to a triathlon set-up without having to upgrade my whole groupset. I have purchased regular DuraAce base-bar TT shifters and want to get either the DuraAce SW-R9160 TT shifters or the DA SW-R671 shifters. What are my options? I know regarding the latter I could use a B-junction to connect the two new wires into my existing SM-EW90 junction box. Would I need to upgrade anything else? Many thanks!

Wonder if removing the 3.2.2 version and installing the 3.2.1 would make a difference? Might be worth a shot.

I have run both version with no issues.

After tinkering with my DI2 components I wonder

… for which purpose junction A was made a mandatory component rather than optional? From an engineering perspective it should be fine to just strap battery (BT-DN110), motor unit (MU-S705) and shifters (ST-R785). Even for charging I should be allowed to just undo my seat post and charge the battery directly from a (modified) SM-BCR2.

… how @DI2DIY made his custom batteries work? I tried it myself but only saw the voltage drop to 1V. Do I have to disassemble an external battery holder and solder the electronics onto my large capacity batteries?

… what all this signalling means when the diagnostic unit is attached? @Ghislain? This was how I could at least breathe some life into my assembly, briefly. It looks like a pulse code modulation but my sampling rate was too low to be any more specific and until I find a way to charge the battery (junction a is still missing) and can’t do it again 🙁

… what are the signalling properties of the CAN in use? Symbol frequency? Levels? I saw some chatter with 1/4 and 1/2V swings on different baselines. I never decoded CAN before.

SM-EW67 manual suggest that you have to use ports in specific order

i.e. connect to wired ports to shifters, and connect unwired port to derailleurs/battery via junction b

SM-EW90 manual suggest that you can connect anything to any port

Anyone can confirm that SM-EW67 is really limited to specific port usage?

or you can use ports in any order (connect derailleurs/battery, shifter to any port)

The only requirement for the A junction 67/90 is that it’s plug in to the system, it does not have to have anything plugged in to it, but can be plugged into any other components in any order.

Hi I have a Durace DI2 10 Speed 7970 system and has always worked fine. A week ago the front dropped into the small chain ring and would not shift to the big chain ring. About 80kms later it started working normally.

This weekend it stayed in the big chain ring and again would not shift. The rear works fine and shifts normally. The battery is fully charged and I have tried a 2nd battery but to no avail. I have also notice a ticking sound coming from the front derailleur. The ticking sound stops when I unplug the cable going into the front derailleur

Any ideas as where to start fault finding

Thank you

Yea, I had the same problem. Eventually the front derailleur stopped working altogether and then the back as well. Was due to the old wires getting moisture in them and corroding away. Suggest you take off the FD and test, if it works OK it’ll be corroded wires between the FD and gear levers.

Thank you will try that

Lochearnhead did you manage to clean up the wires or able to source new one’s?

Sorry predictive text Lochie

LOL!

Unfortunately I could not clean the wires or get new cables… they are almost impossible to get (at least in Australia). I bit the bullet and upgraded to 6870.

To test if it’s the FD, or the wire… remove the FD plug it in to the RD cable, if it shifts ok than it’s the FD cable, if it won’t shift than it’s the derailleur

Amazing article – thanks! Help is needed

I have Ultegra Di2 10sp (Focus Chrono 2.0 2012 TT bike) with regular brake lever…(Tektro) The only shifters i have is the Aero-bar end SW-R671.

I really want to add only a right side – rear derailleur shifter (10sp) for out of the aerobar shifting (Climbs, corners, out of the saddle etc…) My junction box is 3 port (SM-EW90-A) and obviously full.

To avoid buying an expansive dual TT shifter/lever I thought buying a climbing shifter and attach it to the right base bar end next to the brake lever on the inside. (It will work fine with a 10sp setup right?)

Do I have to buy this – “SM-EW90-B Dura-Ace 5-Port Junction” for the extra connection or can I attach the climbing shifter in a different way?

Money is an issue so I would like to know what is my cheapest option… Thanks!

Anyone? If it’s possible to do a manipulation with what i have currently I’d like to know….

My reading says you will need a 5 port junction box and then all will work. You could alternatively cut some wires and solder things together. If you need further instruction on the wire soldering method, then don’t do it.

You might consider just buying an individual TT brake lever, which although is more money might well be aero cleaner.

That’s correct, or you can use a Junction B to add more ports up front, which will be messier but possibly cheaper.

How do I charge my battery pack when traveling in Europe ( from US)?

With the battery charger.

You can connect the charger into any USB charger or your USB connection on your laptop or simply use the appropriate adapter and charge directly from the power supply, as Di2DiY suggests.

This is a terrific post. Thank you for sharing. After reading all this, it would appear that there are no wireless options for D-fly and a SM-BMR1 – correct?

Hi I’m trying to set the gears on my ultegra di2. but I cant get it to change smoothly when its connected to e-tubeproject

it is in gear 4 on the bike but on the laptop I is saying its in gear 5 and how can I change this.

I’m running Dura-ace DT-9070 Di2 with internal battery. The set-up works fine and I can enable syncro and semi-syncro modes via e-tube project. However in manual mode the RD refuses to change onto the smallest or second-smallest cogs when the FD is on the smaller cog. Is this a system design thing to stop cross-chaining? Can I override it?

Hello Carlton and thanks for putting this page together for us who need a better understanding of how di2 works. I have a 2013 Caad10 Black Inc that came with Ultegra 6770 di2 and I’m in the process of upgrading the components to 11 speed Ultegra 8050 with an internal battery. I have purchased the new bar end junction box, new Bluetooth enabled internal battery, slim inline Bluetooth/ANT transmitter, charger, and several cables to connect everything.

My question is, will everything I’ve purchased so far work with my existing Ultegra 6770 so I can ride until the new Ultegra 8050 components are available for purchase? Also, will my 6770 shifters work with the new 8050 group?

David,

The best reference for your question is the “E-Tube Compatibility Chart”. The most recent is version 3.2.2, released on May 24, 2017.

It is located at: http://e-tubeproject.shimano.com/pdf/en/HM-CC.3.2.2-00-EN.pdf

To help address your question, I will make the following parts assumptions. The Bar End Junction is an EW-RS910, Internal Battery is a BT-DN110 and BT/ANT unit is an EW-WU111.

You didn’t mention what model the existing shifters are.

Based on the compatibility chart, all of your new components should work with your 6770 derailuers as long as the shifters are compatible.

I assume you are using the RS110 Bar End junction box with the intention to route all cables internal. Routing cables inside the bars can be challenging. Many bars have reinforcements built in them between the drops and hoods making cable routing more difficult than it seems on the surface. A number of newer bars are available to address this issue.

Hope this helps.

Jim

Thanks Jim, I plan to use all of the new parts you listed above with my existing 6770 shifters if they’ll play nice with everything else. If not, it’ll give me a reason to buy the new R8050’s which have some new features that look nice. I’ll also admit I’m only hopeful at this point to be able to route the wires internally with my existing bars as I haven’t tried to pass a fish wire through them yet. If the wires will pass, it seems I can make things look pretty neat with only one wire leading to the frame in place of the old SM-EW67A-E junction. If not, I’ll be in search of some new bars. So far I only see Pro Vibe’s being available for internal di2 routing, what are some other brand bars to looking for?

Just a followup on my installation of the bar end junction EW-RS910, Internal Bluetooth Battery BT-DN110-1, and inline Bluetooth Transmitter EW-WU111. Installed everything yesterday and it worked right out of the box with my Ultegra 6770 10 speed shifters and 6770 Front/Rear Derailleurs. I also updated the firmware on all of my components to the latest versions using Shimano’s etube app on my cell phone via Bluetooth, pretty cool!

Anyone have any idea as to when Shimano is going to release the new Ultegra R8050 di2 components? They were scheduled to be in stock at a few online shops yesterday but now the dates are being pushed back anywhere from the end of August to November.

Dave. Glad this all went well.

I really like my Di2 setup, the crisp clean shifts are great, the only downside to me is the cost and remembering to charge the battery a couple times each riding season.

No issues routing the cables through your bars?

No problems, ended up looking pretty clean. Only thing you see up front is the inline Bluetooth unit but its hidden pretty well below the stem. I used some heat shrink to run the etube wire along with the rear brake cable where it goes into the frame. I did drill some holes as a temporary solution just below the shifter clamps to run the wires and the tape hides everything. I do plan to get the new Pro Vibe bars when they become available.

I placed my EW-WU111 Bluetooth unit just below the battery in the seat tube. It worked out fine in my carbon frame, but have heard about issues doing this on a metal frame.

Yeah, that’s why mine is external for now as my bike is a Caad10. I had a carbon drop bar on it but decided to put the original C1 aluminum bar back on to drill holes for the new di2 setup just to be safe. Once I get the new PRO Vibe carbon bar, I’ll be able to stuff the EW-WU111 inside one end where it should work just fine.

Anyone with a newer internal battery BT DN110, capable of an accurate diameter measurement? Preferably with vernier calipers. I need to know the diameter of the bare battery without the fitting shims. I’m trying to squeeze one inside a vintage USE titanium post, on an equally vintage ’89 Merlin ‘road’, which is narrow at best. Otherwise I’ll have to bury it in the seatube, but the bottle cage bolt inserts look like they will be in the way. Any help greatly appreciated before I dive in and order one only to find it doesn’t fit.

Mike.

I measured 17mm diameter for BT DN110.

Thanks Carlton, sorry for the slow response on my part!

One cyclocross question (mix derailleurs Road and MTB):

I own a bike with following setup:

Shimano MT-800 Di2 Display

Shifters Shimano R785 Di2 hydro disc

Front Deraillerur None, 40t

Rear Derailleur Shimano XT Di2 , Shimano 105, 11-32, 11-speed

Is it possible to install Ultegra Di2 front derailleur so I can run 50-34t front or is it bad to mix ultegra with MTB XT di2?

The rear XT derailleur is awesome atm but I want higher gears for gravel and paveroads also.

If possible any firmware recommended?

Best regards

Bjarke

Unfortunately you can’t mix the Mountain Di2 rear derailleur with the road Di2 front derailleur. You could run a mountain Di2 front derailleur, but I think there’s a limit on the size of chainring that you can run. Here’s a link to the gravel cyclist tinkering: http://www.gravelcyclist.com/bicycle-tech/tinkering-shimano-xtr-di2-road-shifters/. I’ve been running a 50/34 with 11-40 on Ultegra Di2 6870 GS derailleur and Ultegra Di2 6870 FD using the Wolftooth components roadlink: https://www.wolftoothcomponents.com/products/roadlink

I’ve wondered if the limitation on mixing Road and Mtn Di2 was some mechanical limitation or because Shimano chooses not to make it work by firmware?

I’m pretty sure it’s a firmware issue to limit liability. You can’t run a mountain FD with the larger chainring as it is a mechanical issue I believe.

I have an XTR FD on a road compact crankset. It works well, if not quite as smoothly as the ultegra FD. It is annoying you can’t mix these, I have a bike that I use as a road bike for big long trips where I want the 50T front ring, but I also use as a gravel bike and want the clutch rear mech and extra range.

Seems to be its gotta be firmware and they could choose to make them compatible with firmware if Shimano wanted to. I can’t think of a technical mechanical reason why the mtn rear and road front couldn’t talk and work with each other as long as one doesn’t cross chain too much. If I use a 32 on my rear Dura Ace Di2 and am inadvertently cross chained with the compact 50 big ring, I get chain rub on the top of the front derailleur cage (smaller bike lower bottom bracket). I can move the FD a bit higher to avoid this but but then shifting isn’t quite as awesome and there is no good reason to cross chain. But synchro shift takes care of all this (it’s awesome). So with synchro shift it should be possible for a rear Mtn Di2 and Front Road Di2 to work without getting into trim or chain rub issues if firmware allowed it.

Hi, Excellent article, thanks.

For my sins, I have the Alfine Di2 11 speed hub and cannot get it to reliably engage 10th and 11th gears. Everything has been updated, I have performed an oil change and tried every available adjustment to the motor. Any ideas?

Also, can you tell me what the little “M” means on the display (as shown on your MT800 image)?

Thanks,

Steve

Just upgraded to Di2 on my new Cannondale Synapse. Very grateful for the information you have put together. Grazie Mille!

Hi Carlton, Thanks to your instructions, I made my 6770 Ultegra 11 speed with the addition of the RD6870 and old software version update and it worked great.

Just replaced old battery with a new SM-BTR1 and to my relief it’s still 11 speed. I wanted to add the R600 climbing shifter, so plugged it in to ST-6770 and it doesn’t work. Is this because Ive got the SM-EW67-A-E Ultegra 3-Cable Junction? and if so, do I need the SM-EW90-A Dura-Ace 3-Port Junction to make it work? Thanks in advance, I had a look through previous comments but may have missed a similar question.

First, unplug an existing shifter and plug the climbing shifter directly into the 3-port junction and see if it works. Second, you may need to downgrade the firmware to match your other components.

I can’t remember off the top of my head if the ST-6770 has a sprint shifter only port. If so, then the climbing shifter wouldn’t work.

Thanks, I’ll get hold of a 3port junction and try it.

Didn’t have the 3 port junction, so bit the bullet and bought the FD-6870 to see if it would work. Still no luck so got a friend with the pce1 to update all firmware to current and sure enough the r600 and everything works well. Thanks again for your help.

Hi Carlton, a few questions, once the bike is set up and shifting does the junction A need to be on the bike i.e. can it be shared between bikes or are bike specific derailleur settings stored on it? Instead of the junction B could the wires be soldered together? Are there any non Shimano 8.4v DC 0.4A chargers that a EW SP50 wire can be spliced onto? Many thanks.

I am curious if I can charge the BTR1 battery through a hack? I do not want to spend the money on an external charger as my old one just broke. Any help appreciated I have a BCR2 and EW90A from another bike I can cut up, but I don’t think it will work. Is there a dc voltage I can set and attach wires to on the BTR1 from another charger?

Were you successful? Similarly I want to have a small battery pack (7.4v) that I can plug into the charging port in an emergency situation (forgetting to charge), however the odd duck connector of the charging port has me stumped. Any idea if there is a suitable connector on the market?

It can ONLY be charged with the BCR2 charger, but you can plug a USB battery backup into the BCR2 to charge, so you would not need an AC outlet. Check the battery level regularly and there will be no emergency.

For the original post, you can not charge a BTR1 with a BCR2.

Thanks again, yeah eapathome gave me a heads up about the charger chip communicating with the battery chip to open the gate for current to pass.

And yes, I need to be more diligent in charging.

Thanks again!

I’m the same person. I’m a contributor on Carlton’s site.

Firs, thanks for all you have done. I have put three Di2 systems together with your help.

My current system, however, is perplexing me.

It’s the newer 9150 FD and RD, with the non-series 785 brifters. Bar end junction A, internal B. Blue Tooth enabled.

I ride with cross chainrings in 36/46 and usually a 12-25 cassette. For some reason I cannot get my E-Tube program to allow me to set those chainrings. I can create a profile for it, but the program displays a red warning symbol and says that such gearing is not allowed on my bike, So, I lie to it and tell it I’m running a 34/50. It works, but the situation is perplexing. I also note that it oddly keeps me from the two smallest cogs (can get to neither the 12 nor the 13) when in the small ring. Nothing I do will get it to let me run further down the cassette. I can understand it disallowing the full-on cross-chained situation of (what it thinks is the) 34-12, but I’m perplexed that it disallows (what it thinks is) the 34-13 WHILE it allows me to get into (what it thinks is) the 50-23, which is a worse state of cross chaining than the 34-13.

Can you comment on any of this?

What an excellent resource.