I learned quite a bit about Shimano Di2 when I installed one of the first available Time Trial/Triathlon groupsets on my Cervelo P2. I’ve subsequently answered a lot of questions on forums and article comments, and elsewhere. In doing so, I realized that people have a lot of questions about Di2 and the answers are difficult to find. This lead me to create this article, to consolidate everything I know and have been asked into one location so people can find answers. If you can’t find what you’re looking for below, please leave a comment and I’ll do my best to help.

I learned quite a bit about Shimano Di2 when I installed one of the first available Time Trial/Triathlon groupsets on my Cervelo P2. I’ve subsequently answered a lot of questions on forums and article comments, and elsewhere. In doing so, I realized that people have a lot of questions about Di2 and the answers are difficult to find. This lead me to create this article, to consolidate everything I know and have been asked into one location so people can find answers. If you can’t find what you’re looking for below, please leave a comment and I’ll do my best to help.

Index: There’s lots of info in this post, so here’s an Index to help you find specific sections:

- Di2 General Overview

- Compatibility: Between 6770 10-speed, 6780 11-speed, 9070 11-speed, first-gen 7970

- How to Check Battery Level

- How to Adjust Rear Derailleur Trim

- How to Adjust Front Derailleur Trim

- Dealer Installation Manuals

- Shimano E-tube Project Software – Change Settings and Update Firmware

- Chargers, PC USB Interfaces/Programmers

- Component Overviews

- Shift/Brake Levers

- Dedicated Shift Buttons

- Front Derailleurs

- Rear Derailleurs

- Display Units and ANT Bluetooth Wireless Communication Modules

- Batteries and Battery Mounts (Internal and External)

- Front Cable Connection A Junctions (with charger ports and LED status lights)

- Rear Cable Connect B Junctions

- Cables, Grommets, Cable Install Tools

- List of Components Needed to Build Your Own Di2 System

- Technical Details of the Di2 CANBUS protocol and signaling

System Overview: Shimano Di2 Dura-Ace 9150 and 9070 and Ultegra 6770 and 6870

The second generation Shimano Ultegra 6770/6870 and Dura-Ace 9070 “E-Tube” electronic bicycle shifting systems consist of battery-powered electric derailleurs activated by handlebar mounted push buttons. Power and shift commands are sent via a 2-wire CAN (Controller Area Network) datalink contained within a single cable housing. This design has several advantages over conventional mechanical shifting systems, the most notable of which are:

- Extremely low shifting effort, which generally results in more frequent shifts and therefore better gear ratio selection.

- Greatly improved shift quality, especially for the front derailleur chainrings, allowing shifting under full power with almost no chance of a dropped chain.

- Shifting is available at multiple positions on the handlebars, for example, at the end of the time trial aero bars, on the brake levers, up to in climbing position, and down low the sprint position.

- Automatic trimming of the front derailleur position as the rear derailleur moves back and forth between the smaller and bigger gears. This eliminates unintended contact (and noise) between the front derailleur and the chain.

- Lighter weight vs. equivalent mechanical system. The Shimano Dura-Ace Di2 9070 electronic groupset with internal battery weighs 2047 grams; the Shimano Dura-Ace 9000 mechanical groupset weighs 2074 grams (27 grams more than Di2.)

- Multi-Shift: Pressing and holding a rear derailleur shift button results in shifts through multiple gears. The rate of shifts can be configured using the PC computer interface cable and the free Shimano E-tube Project software.

- Synchronized Shifting: Starting with Dura-Ace 9150, automated Synchronized Sifting of the front derailleur is an option. Two SHIMANO Synchronized Shift modes will be available:

- Full SHIMANO Synchronized Shift: the front derailleur reacts based on the rear derailleur’s shift action. This essentially means that, when activated, there is no need for two separate shifters to control front and rear derailleurs, the two buttons on one shifter will control both derailleurs.

- Semi SHIMANO Synchronized Shift mode: the rear derailleur reacts based on the front derailleur’s shift action, shifting to the next most appropriate rear gear when the rider makes a front shift.

- R9120, R9170 – syncroshift enabled with firmware 3.2.0 or newer

- 6870, 9070 – syncroshift enabled with firmware 3.2.1 or newer

- 6770 – no syncroshift firmware update will be offered

Historic Info on the older first generation 5-wire Shimano Dura-Ace Di2 DA-7970 system and how it compares to the new E-tube 2-wire system:

Historic Info on the older first generation 5-wire Shimano Dura-Ace Di2 DA-7970 system and how it compares to the new E-tube 2-wire system:

Released in 2009, the 7970 operated using a very basic 5-wire electronic system. Each shift button was connected to a different wire; shorting the specific wires together controlled the derailleur upshifts and downshifts. Because the first generation 7970 used completely different technologies than the newer 2-wire systems, none of the components are cross-compatible. At this point, Shimano is not expected to offer any updates or new components using the first generation 7970 architecture; everything from now on will be based on the newer 2-wire E-tube design. The second generation design offers several advantages, which include: 1) smaller wire size, smaller connector size, waterproof connectors; 2) all switches can be reconfigured in software to send upshift or downshift commands to either the front or rear derailleur; 3) firmware updates can add new features (such as multi-shift) and compatibility with new components.

Compatibility: Dura-Ace 9070 and Ultegra 6770 / 6870 (and old 5-conducter 7970)

The confusing naming system used by Shimano makes it difficult to figure out what each component is, much less what is compatible between systems. Here are some compatibility guidelines:

- Nothing from the first generation (4-conductor / 5-conductor) Dura-Ace Di2 7970 system is compatible with any other newer system. It was replaced by the (2-conductor) E-tube systems. No parts are inter-operable between 7970 and any other Di2 System.

- In general, every electronic Di2 component is compatible between the Ultegra 6770, 6870, and Dura-Ace 9070 systems (see exceptions below.) This means that all of the road bike Ultegra/Dura-Ace dual control brake levers/shifts, time trial shifters, and climbing shifters can be used with either Ultegra 6770/6870 or Dura-Ace 9070 front and rear derailleurs. Any of the Ultegra/Dura-Ace controllers (A Junctions) can be used with either system. All components use the same cables and connectors.

- Firmware Update Required to Make Older Components Compatible with Newer Components: If you add a new component and it doesn’t work, update the firmware using the PC USB adapter and the Shimano E-tube Project Software for Windows.

- Synchronized Shifting and Bluetooth Wireless Units can be added to all E-tube Ultegra and Dura-Ace systems but the battery has to be upgraded to the BT-DN110 Internal Battery or BM-DN100 External Battery Mount. To add Bluetooth capability, a EW-WU101 or EW-WU111 inline transmitter must be added to road bikes and for mountain bikes, the SC-MT800 or SC-M9051 display/transmitter unit must be added.

- Compatibility Exceptions:

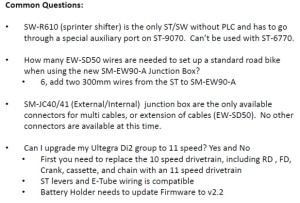

- Note 1 – Sprint Shifter Exception: The Sprint Shifter is the only exception for shifter incompatibility. It has a different wiring connector (and internal components) that can only plug into a unique/dedicated third port on the Dura-Ace ST-9070 Dual Control Brake Levers/Shifters and also the ST-6870 Levers. There is no sprint shifter port on the ST-R785 Hydraulic Levers.

- Note 2 – Can’t mix 10-speed/11-speed front/rear Derailleurs: It is no longer possible to use a 10-speed front derailleur with an 11-speed rear derailleur (and 11-speed front with 10-speed rear.) See note farther below to read the history on this if you want all the messy details.

- Note 3 – Front A junction and Internal Battery: Since the February 2015 firmware update, the older SM-EW67-A-E Front Junction A is no longer compatible with the BTR2 Internal Battery because it does not have the charging port to charge the internal battery. The SM-EW90 Front Junction (with integrated charging port) should be used instead. The SM-EW67 still works with the external battery.

- Note 4 – Update the Firmware to make components compatible: If the firmware on all components is not updated to the latest version, some components may be not operate correctly with one another. So download the latest E-tube software and update everything and it should work.

- Note 5 – All Shifters work with all 10-speed and/or 11-speed Rear Derailleurs: All of the shifters are compatible with either the 10-speed Ultegra 6770 or 11-speed Ultegra 6870/Dura-Ace 9070 systems as long as they all have the latest firmware. The rear derailleur is the only component that “knows” or “cares” how many rear gears are available. The shifters only send upshift/downshift commands and do not “know” or “care” which gear is currently selected and how many total gears there are.

- Note 6 – SM-BTR1 External Battery and SM-BMR1 Mount firmware updates: The more expensive dedicate service tool (SM-PCE1 PC Interface) must be used to upgrade the firmware on the external battery/mount.The external battery and battery mount can not receive firmware upgrades via the SM-EW90 Front Junction A and the SM-BCR2 PC Interface/Battery Charger. (The SM-EW90 will work in a system with an external battery, but a firmware update can cause them to become incompatible until both are updated independently using the appropriate PC Interface and the Shimano E-Tube Project software.)

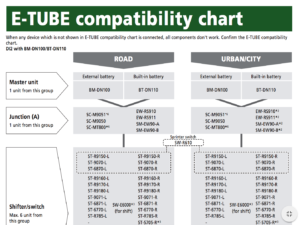

- See the Shimano E-tube compatibility chart version 3.4.3 for more details

Compatibility: 11-Speed Rear Derailleur and 10-speed sprockets/wheels

The 11-speed Dura-Ace 9070 and Ultegra 6870 rear derailleurs are designed exclusively for 11-speed rear sprockets and 11-speed Front Derailleurs. Shimano does not provide a way to recalibrate/reprogram them for a 10-speed setup. The sprocket spacing is slightly smaller and the overall range of travel slightly longer on 11-speed systems. If you have 10-speed wheels and 10-speed sprockets, you should use the 10-speed RD-6770 rear derailleur and a 10-speed FD-6770 front derailleur.

Similarly, a 10-speed RD-6770 rear derailleur should not be used with 11-speed sprockets. There will be chatter in some gears, and there might be slow-shifts or self-shifts.

It doesn’t matter which shifters are used; the shifters send upshift/downshift commands regardless of which derailleur config is being used. Shifters do not “know” or “care” which gear is currently selected and how many total gears there are.

Front Chain Rings: In general, most any front chain rings will work, rigid forged rings work best with Di2 due to high front derailleur shift forces. Shimano chain rings tend to be the best, but most others work as well. A 10-speed specific or 11-speed specific chain should be used, but the differences between them are minimal and can generally be mixed/matched without issue.

How to convert “non-upgradeable 10-speed only” wheels such as Zipp 900/Sub9 Disc Wheels to 11-speed: “the spacing between a Campy 11 and Shimano 11 is close enough that you can use the cassettes interchangeably. If you get a Campy free hub body, the 2 shims (part# is on the Zipp website, just search for Campagnolo 11) and a Campy cassette and you’re ready to ride with all 11 cogs available to use.” via slowtwitch.com

But it’s an emergency and I need to use a 10-speed wheel. . . In emergency situations, 11-speed rear derailleurs can be used with 10-speed sprockets. There will probably be chatter in some gears, and there might be slow-shifts or self-shifts. To setup an 11-speed rear derailleur for a 10-speed sprocket setup, adjust the mechanical limit screw so that it can’t shift into the missing 11th sprocket position, then follow the rear derailleur adjustment procedures listed below.

Included for very motivated individuals only: 10-speed front derailleurs can be used with 11-speed rear derailleurs if the shifters and battery have firmware installed from E-tube software version 2.5.2 or earlier. Shimano disabled support for this 11-speed and 10-speed cross-matching with later firmware updates. For informational purposes only, the details of how to regain compatibility are detailed below.

- Important Notice 2014-07-14: There is a compatibility issue with Shimano e-Tube software/firmware versions v2.6.0 and later that prevents 10-speed front derailleurs (FD-6770) from working with 11-speed rear derailleurs (RD-6870) and 11-speed front derailleurs (FD-6870) from working with 10-speed rear derailleurs (RD-6770). DO NOT UPDATE FIRMWARE using Shimano e-Tube software v2.6.0 or later if you are mixing an FD-6770 front derailleur and a RD-6870 11-speed rear derailleur, or a FD-6870 with a RD-6770.

- The problem component is the battery (external battery mounts SM-BMR1 and SM-BMR2, internal seat post battery SM-BTR2.) If you keep battery firmware at v2.0.6 or earlier, the system will continue to function properly. Shimano e-Tube Software v2.6.0 will update battery firmware to v3.0.5, and will not allow the RD-6870 to work with a FD-6770 setup.

- If the battery firmware is updated to 3.0.5, it CAN NOT be rewritten back to the older version. You will need to need to replace a derailleur so that both are 6770 10-speed or so that that both are 6870 11-speed. (The other option is to get get a battery with the older firmware and never update it.)

- Here’s a link to the “last known good version” of the Shimano e-Tube software to work with a mixed 10-speed/11-speed system: E-tube_Proj_V_2_5_2.zip Use this version and do not connect to the internet when using it so that E-tube can’t check for updates when open.

- To roll-back newer versions of battery and shifter firmware, install E-tube version 2.5.2 and made a copy of “C:\ProgramData\E-tube Project\FW” which has all the firmwares packaged in that version of E-tube. Next, install the latest version of E-tube. Then copy all the firmwares from the the 2.2.3 version back to the same location “C:\ProgramData\E-tube Project\FW” for the latest version (note: ProgramData is a hidden directory, click here for details on how to view it.). Next, the trick is to find the firmware you want to downgrade (pretty easy from the name and version in the file name), and then rename it to the same name as the latest version, but increment the last version digit by one. Then connect to the bike with E-tube (without an internet connection) and it will identify that a firmware upgrade is available for that component and allow you to do the firmware “upgrade” to the older version of firmware. Now exit E-tube and then rename the firmware file back to original to prevent the issue in future. E-tube will then try to upgrade again but just don’t let it do that. This should get a bike that did nothing (not even enter adjustment mode) to a fully working state by reverting the battery and shifters. Running latest firmware in derailleurs seems to be fine. (thanks to commenter vosadrain)

- It will not be possible to charge the BTR2 internal battery using the BCR2 USB charger unless you also downgrade the firmware of the BCR2 USB charger as well.

- Note however that latest E-tube software will say the setup is unsupported and will not allow programming. To do programming, disconnect the internal battery and connect a spare external battery. This allows making settings changes. To program the BTR2 itself, I just connect to the BTR2 by itself (no other components) and the E-tube software will allow firmware changes to it. Or try using the 2.5.2 version of E-tube.

- Alternatively, buy a Di2DIY internal seat post battery kit and you will not have to go through the firmware downgrading. The kit makes it possible to run all components with the latest E-tube firmware. Also worth noting some firmware updates were done to fix power distribution errors in the FPGA’s that would allow the batteries to drain down when the bike was just sitting.

Checking Battery Charge Level:

A single battery charge should give at least 1500 miles of riding. Most riders will not need to charge the battery more than twice a year.

To check the battery charge remaining, press and hold any shifting switch for 0.5 seconds or more. The amount of battery charge remaining will be indicated by the light on Front Controller A Junction.

- 100% remaining: Illuminates green (for 2 seconds)

- 50% remaining: Flashes green (5 times)

- 25% remaining: Illuminates red (for 2 seconds)

- 0% remaining: Flashes red (5 times)

When the battery charge is low, first the front derailleur will stop operating, and then the rear derailleur will stop operating. When the battery charge has been fully spent, the derailleurs will be fixed at the last gear shifting position. If the battery indicator is illuminated red, it is recommended that you recharge the battery as soon as possible.

Adjusting the Rear Derailleur Trim:

If you switch between multiple rear wheels, it’s very likely that the sprockets on different wheels won’t be in exactly the same relative position to the rear derailleur, resulting in that annoying clicking sound as the chain makes contact with an adjacent sprocket. Follow the steps below to properly align the rear derailleur with the rear sprockets.

- Shift the rear derailleur to the 5th sprocket position. Press the button at the junction (A) of the SM-EW67-A-E until the red LED illuminates in order to switch to rear derailleur adjustment mode. Note that if you keep pressing the button after the red LED has illuminated, protection recovery operation will begin.

- If shifting switch is pressed once while the initial setting condition is active, the guide pulley will move one step toward the inside. If shifting switch (Y) is pressed once, the guide pulley will move one step toward the outside.

- Note: The guide pulley can move 15 steps inward and 15 steps outward from the initial position, for a total of 31 positions.

- Note: When adjusting, the guide pulley will overrun slightly and then move back in an exaggerated movement so that you can check the adjustment direction. When checking the positions of the guide pulley and the sprocket, check at the position where the guide pulley finally stops.

- While turning the front chainwheel, operate shifting switch to move the guide pulley toward the inside until the chain touches the 4th sprocket and makes a slight noise.

- Next, operate shifting switch 4 times to move the guide pulley toward the outside by 4 steps to the target position.

- Press the button at junction (A) until the red LED turns off in order to switch from rear derailleur adjustment mode to gear shifting mode. Shift to each gear and check that no noise is generated at any gear position. If fine adjustment is needed, switch back to adjustment mode and readjust the rear derailleur.

- Note: if you have customized your shifters and swapped buttons, this will change which shifter and buttons control the micro-adjustments. Also, if you hit the wrong buttons while trying to set the FD trim, you can actually alter the setup of your RD. Be certain that you’re hitting the correct adjustment buttons.

- If you have a Garmin or similar head unit and a SM-EWW01 ANT module, the display will automatically switch into derailleur trim display when you activate that mode (i.e. by pressing the button at the junction (A) of the SM-EW67-A-E.) It will give you the trim position in either + or – 12 positions. When switching wheels, simply take note which position suits which wheel/sprocket/trainer, and trim to that level each time you change. This removes the guesswork and makes changing from wheel to trainer simple.

Note on FD-6870 Front Derailleur Trim:

The FD-6870 trim adjustment effects the auto-trim positions. The adjustment feature is accessible via either the A-Junction box, or the “Front derailleur adjustment setting” in the e-tube software, and should be used only after you have already set the physical inner/outer limit screws. So for example, if the FD outer plate rubs the chain when using the 6th largest cog, you would want to adjust the FD trim outward a couple ticks. However, you can only perform this adjustment while in the big-ring/big-cog combination. Etube forces the derailleurs into this maximum cross-chained position, whereas during the manual method you must shift to these positions yourself. (Thanks to commenter Bryan B for the info.)

Dealer Manuals:

The dealer’s manuals contain the most detailed information available from Shimano. If you’re looking for detailed installation instructions, check here:

- Shimano Ultegra 6770 Dealer’s Manual: http://techdocs.shimano.com/media/techdocs/content/cycle/SI/Ultegra/UltegraDi2/6770Di2_DM_EN_v1_m56577569830773882.pdf

- Shimano Ultegra 6870 Dealer’s Manual: http://si.shimano.com/php/download.php?file=pdf/dm/DM-UL0001-00-ENG.pdf

- Shimano Dura-Ace 9070 Dealer’s Manual: http://si.shimano.com/pdf/dm/DM-DA0001-00-ENG.pdf

- Shimano Alfine Di2: http://si.shimano.com/php/download.php?file=pdf/dm/DM-AL0001-03-ENG.pdf

Shimano E-tube Project Configuration and Firmware Update Software for Windows:

Shimano E-tube Project Wireless for iOS and Android: Announced on April 15, 2016 but as of yet unreleased, these apps will allow configuration of shift profiles (multi-shift on/off, multi-shift delay between shifts, shifter button assignments) and firmware updates over Bluetooth. To function, a Shimano Di2 Bluetooth Adapter, such as the MT800 digital display, is required.

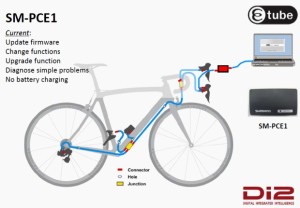

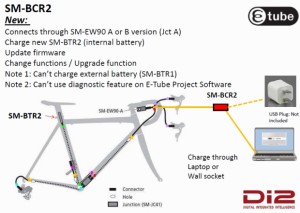

Shimano E-tube Project Windows PC Software: This free software is used to update the firmware of all components. It works with the SM-BCR2 Charger + USB Adapter and the SM-PCE1 Diagnostic Adapter. The software is used to change the configuration of each shift button / lever (any can be programmed to upshift or downshift either the front or the rear derailleur.) It can also be used to enable multi-shift (multi-shift is where the shifter is held and the rear derailleur shifts through multiple gears until the shifter is released.) The delay between of the gear changes during multi-shifting can also be adjusted. The software is available from http://e-tubeproject.shimano.com/

Older versions of the e-tube software are available from these links: 2.5.2

PC & Mobile Interfaces, Chargers, and Software:

SM-BCR1 Battery Charger: This is used to charge the external battery. The part number for the battery charger wall cord is SM-BCC1.

SM-BCR2 Charging and PC Connection: for SM-EW90-A 3-port and SM-EW90-B 5-port A Junctions. This plugs into a special port on the side of the A junctions (which is covered by a rubber flap.) This adapter charges the internal battery when first plugged into the A junction; it must be powered by a standard USB Wall charger (such as that used for an Apple iPhone) or a PC that is powered-on. If the Shimano E-Tube Project Software is launched on the Windows PC with the SM-BCR2 attached, the SM-BCR2 will switch from charging mode to configuration mode. It must be detached from the computer and reattached to switch back to charging mode.

- It takes about 2 hours to charge the internal battery.

- Amber light=charging.

- Light turns off when done.

- If the Amber light does not come on when plugged in, this indicates battery is not discharged enough to charge.

- Light flashing indicates something is wrong, like trying to charge a external battery through a BMR.

Hacking the SM-BCR2 to have a standard Di2 cable connector: If your 3-port or 5-port junction is inaccessible for charging, there is an alternative hack method to connect it to the system through a standard Di2 port. With basic soldering skills you can hack the BCR2 to be used with any setup. Buy any length EW-SD50 wire, cut off one end. Cut the wire on the output side of the BCR2. Splice the two wires together, so that the output wire of the BCR2 is now a standard Di2 connector. The charger has an inner (white) and outer (shield) wire; connect the inner white wire to the SD50 red wire; connect the charger outer shield wire to the SD50 black wire. You will then be able to plug the BCR2 into any Di2 port. Or use a SM-JC40 junction B and another length of EW-SD50 wire and go through the RD (by using the SM-JC40 to connect the rear derailleur, new output wire of the EW-SD50, and the wire that ordinarily connect the rest of the system to the rear derailleur.) Thanks to @Di2diy for the info.

SM-PCE1: This PC Configuration and Diagnostics adapter will not charge the internal battery. It offers the same configuration options as the SM-BCR2, but also add some advanced diagnostic and troubleshooting features that the SM-BCR2 does not have. It attaches to via the standard E-tube wire (just like the EW-SD50 cables) rather than to a dedicated port on the side of the front A junction.

Bluetooth and E-tube Apps for Apple iOS and Android: Bluetooth wireless modules are available to allow system settings to be adjusted via the mobile applications that connect via Bluetooth Adapters.

Component Overview:

The confusing naming system used by Shimano makes it difficult to figure out what each component is, much less what it does and how it fits into an a complete Di2 system. Here’s an overview of all the major Ultegra and Dura-Ace Di2 components.

Dual Control Brake Levers/Shifters (a.k.a. Brifters):

ST-6770 Ultegra Road Dual Control Brake Levers/Shifters: The Ultegra version can be used with the climbing shifters. They are sold in in left/right pairs and are also available separately.

ST-9070 Dura-Ace Road Dual Control Brake Levers/Shifters: The main advantages these have over the ST-6770 version is slightly lighter weight and compatibility with the low-mount sprint shifters. As like the Ultegra version, they are compatible with the climbing shifters. They also have hidden button under the rubber hoods that can activate screen changes on cycling computers from Garmin, Magellan, Pioneer, and Shimano (Shimano SM-EWW01 ANT Wireless Broadcast Module required.)

ST-9071 Dura-Ace Time Trial/Triathlon Dual Control Brake Levers/Shifters: These levers provide shifting from the pursuit bar position on time trial bikes. There is no Ultegra option offered at this time. These are available as left/right pairs, or can be ordered separately. These do have a permanently attached wire with a male end for connection the the SM-EW90 front “A” junction. Combined weight both levers: 117 grams.

ST-R9160 (standard cable brakes) and ST-R9180 (hydraulic brakes) Time Trial Dual Control Brake Levels/Shifters: These are the lower-profile shifters offered with the newer Dura-Ace R9150 groupset.

ST-6871 Ultegra Time Trial/Triathlon Dual Control Brake Levers/Shifters: Ultegra version of the ST-9071 Dura-Ace shifters. Slightly heavier and much less expensive than the Dura-Ace version. Combined weight both levers: 142 grams.

ST-R785 Hydraulic Road Dual Control Brake Levers/Shifters: These hydraulic road shifters are compatible with both the climbing and sprint shifters. These are compatible with the SM-RT99 centerlock 140mm and 160mm rotors and WH-RX31 wheelset (which as no standard rim brake track.) These require the BR-785 dual piston hydraulic disc calipers. They do not have the special wiring port required for the SW-R610 Sprint Shifters and a SM-EW90-B 5-port junction A is required to use the SW-R600 climbing shifter.

ST-6870 Ultegra Road Dual Control Brake Levers/Shifters: These road shifters are compatible with both the climbing and sprint shifters.

Dedicated Shifters:

SW-R671 Dura-Ace 2-Button Time Trial/Triathlon Bar End Shifters: These shifters are installed on the end of time trial aero bars. By default, the left shifter upshifts/downshifts the front derailleur; the right controls the rear derailleur. For both, the lower button upshifts into a harder gear and the upper button downshifts to an easier gear. This can be changed using the Shimano E-tube Project software; the functions of the left and right sifters can be switched with one another as well. These are available in pairs or separately.

SW-9071 Dura-Ace 1-Button Time Trial/Triathlon Bar End Shifters: These shifters have only one button each and are intended to control only the rear derailleur, with one sending the upshift command and the other the downshift command. (I personally think this version is absolutely worthless. Why have 2 SW-9071 shifters at twice the price and twice the weight, when you can just buy a single SW-R671 Right shifter instead.)

SW-R600 Climbing/PAVE Shifter: This shifter is for road bikes and is mounted on the upper horizontal portion of the handlebar, or any other location comfortable for the rider. They can be used in addition to the Dual Control Brake Lever/Shifter, or can be used on their own by plugging directly into a SM-EW90-A 3-Port Junction or SM-EW90-B Dura-Ace 5-Port Junction.

SW-R610 Dura-Ace Sprint Shifter: This is the only component using a unique wiring connector; it is only compatible with the ST-9070 Dura-Ace and Ultegra ST-6870 Road Dual Control Brake Levers/Shifters. Unlike all of the other shifters, the sprint shifters do not contain a circuit board; they do not show up as components on the CAN bus network. Instead, the sprint shifters are simple momentary switches that activate the circuit board on the host Dual Control Brake Lever/Shifter. The host dual control lever is what sends the shift command. (Note: Any momentary switch can be attached to the sprint shifter port on the Dual Control Levers by splicing into a standard EW-SD50 wire to act as remote shifters.)

Alfine SW-S705 Right Flat-Bar Shifter: Reported to work with other non-Alfine setups.

SW-R9160 Time Trial bar-end shifters (pair): These are-end shifters directly control the rear derailleur, with one for the upshfit and one for the downshift. The front derailleur is controlled automatically via automatic Synchronized Shifting. These shifters require the BT-DN110 Internal Battery for synchronized shifting.

SW-R9150 Climbing shifters (pair): These tiny climbing shifters are about as small as the sprint shifters, but can be directly connected to a junction box and do not have to be connected as slave buttons to a brake/shift lever special port. They come with plastic mounts to make it easier to attach to bars beneath bar tape. They are ideal for synchronized shifting, with one controlling the upshifts and the other downshifts. These shifters require the BT-DN110 Internal Battery for synchronized shifting.

Front Derailleurs:

FD-6770: Ultegra Front Derailleur

FD-6870: Ultegra Front Derailleur, pretty much identical to the FD-6770 but with a slightly larger diameter adjusting screw (to better dissipate the shifting forces).

FD-9070: Dura-Ace Front Derailleur

FD-R9150: Dura-Ace Front Derailleur for 9150 systems; features slightly reduced weight vs. 9070.

Rear Derailleurs:

RD-6770: Ultegra 10-Speed Rear Derailleur, compatible with gears up to 28 teeth.

RD-6870: Ultegra 11-Speed Rear Derailleur, compatible with gears up to 32 teeth (for the GS version).

RD-9070: Dura-Ace 11-Speed Rear Derailleur, lighter weight version on which the RD-6870 is based.

RD-R9150: Dura-Ace 11-Speed Rear Derailleur with 30-tooth sprocket compatibility and modified “Shadow RD” geometry to keep the mechanism close to the rear wheel to help avoid damage in the event of an accident.

Alfine SG-S505 and SG-S705: The Shimano series targets comfort and urban bikes. It uses an 8-speed (505) or 11-speed (705) internal epicyclic rear hub. It is believed to be compatible with other Di2 ETube components but this has not been verified.

Display / Wireless Communication:

SM-EWW01 ANT Wireless Broadcast Module: This module wirelessly broadcasts Di2 data (front and rear gear selection details, gear ratio, battery life) to a cycling computer using the ANT protocol. It is compatible with Dura-Ace 9070, Ultegra 6870 Di2 and Ultegra 6770 E-tube road shifting systems. SM-EWW01 plugs into the E-tube wiring system between existing components. It has an 2 wiring ports, so it can be connected between a front shifter and the Front Junction A, or at the rear derailleur (between rear derailleur and Etube wire.) It transmits through a proprietary private ANT wireless protocol, which may eventually become a standard public ANT+ protocol. It is powered by the same Di2 system battery. It is currently compatible with the Garmin Edge 1000, Mio 505, and the PRO SCIO cycling computers (with more to come.) The hidden buttons under the hoods of the 9070 shifter levers will switch screens on the cycling computer when paired with this module. It does not currently allow for shifting control from a cycling computer/device and it is not clear that this functionality will ever be offered. The SM-EWW01 is 38mm long, 25mm wide, 12.5mm high, and weighs less than 5 grams. It does not come with any wires; 1 wire would have to be added if adding this module to an existing Di2 system.

EW-WU101 and EW-WU111 ANT and Bluetooth Wireless Broadcast Modules: These modules are similar to the SM-WEE01 but also include Bluetooth capabilities in addition to ANT capabilities. They require the BT-DN110 battery or the BM-DN100 Battery Mount and cannot be used with the SM-EW67 Front A Junction.

SC705 Alfine Display Unit: This unit displays the battery level and the rear derailleur gear selection. It is powered by the system battery and has a port for the SM-BCR2 internal battery charger / USB diagnostic tool. It is primarily designed for Alfine systems (both 8 505-series and 11 speed 705-series). It is compatible with Ultegra and Dura-Ace Di2.

MT800 Digital Display with Bluetooth: Primarily aimed at XT mountain bike applications, this display allows toggling between the 3 synchronized shift modes (where both derailleurs are intelligently coordinated in unison by one pair of buttons, so no need for discrete shifting of the front derailleur.) It also shows battery level, gear position, shift mode and FOX iRD suspension position. The Digital Display required the new BT-DN110 battery. Existing Di2 XT systems are upgradable to be compatible with the new digital display after battery upgrade and firmware upgrade. This display has 3-port Di2 Cable junction and charging port integrated into the back and serves as a Front A Junction.

Batteries and Battery Mounts:

The batteries contain the main controllers for the system. It is therefore required to upgrade the battery to get features released in new versions of Di2 (such as Synchronized Shifting that automatically controls the front derailleur based on rear derailleur shifting.)

SM-BTR1 External Battery: This external battery must be used with the SM-BMR1 battery mount. It is removed from the mount and charged using a dedicated charger.

SM-BMR1 and SM-BMR2 External Battery Mount: This mount attached to bottle cage mount points or other dedicated frame mounts. It is available in 3 different mount lengths: -I (intermediate length), -S (short length), -L (long length). The SM-BMR2 is an updated version of the SM-BMR1.

SM-BTR2 Internal Battery: This battery is typically mounted in the seat post or seat tube of the frame. It is charged by plugging the SM-BCR2 Charging Cable/PC Adapter into the SM-EW90-A or SM-EW90-B Front A junctions.

BT-DN110 Internal Battery: This battery is required for Bluetooth wireless units and road groupset Synchronized Shifting functionality.

BM-DN100 External Battery Mount: This battery is required for Bluetooth wireless units and road groupset Synchronized Shifting functionality.

Front A Junctions:

SM-EW67-A-E Ultegra 3-Cable Junction: This is the original front junction with 2 integrated cables to connect to the dual control brake lever/shifters. The male cable ends on this Front A Junction will not mate directly to the male cable ends on any of the Time Trial/Triathlon dual control brake shift levers or shifters; SM-JC41 Rear B Junctions can be used to connect this front A junction to TT/Triathlon shifters. This Junction works only with External Batteries, not Internal Batteries.

SM-EW90-A Dura-Ace 3-Port Junction: This front “A” junction is most commonly used in road bike setups. 2 ports connect to the dual control brake / shift levers; the third port is for the cable that leads to the bottom bracket junction.

SM-EW90-B Dura-Ace 5-Port Junction: This front “A” junction is primarily used in the Time Trial / Triathlon setups. 2 of the port are for the brake/shifter dual control levers, 2 of the ports are for the aer0 bar bar-end shifters, and the 5th port is for the cable that runs to the bottom bracket (where the B junction joins the wires from the front A junction, front derailleur, rear derailleur, and battery.)

EW-RS910 Internal Bar-end Junction: This junction is installed into the end of a bar or in a dedicated frame port. It facilitates internal cable routing.

B Junctions:

SM-JC41 Internal Junction: This version has the exact functionality as the SM-JC40 external version, but doesn’t have the mounting tab for being bolted to the bottom bracket or wrapping the extra cable lengths. It has 2 ports on one end and 2 on the other, making it more compact. In addition to being located at the bottom bracket to connect the A junction, battery, front derailleur, and rear derailleur, it can be used at the handle bars to join multiple shifters prior to being connected to the A Junction.

SM-JC40 External Junction: This version is intended to be attached to the frame using the bolt that is commonly located underneath the bottom bracket housing. This junction contains no electronics; it’s sole purpose is to join 4 connectors together, which are usually the wire from the front A junction, the battery, the front derailleur, and the rear derailleur. There are wire holders above the housing to capture the extra wire length by wrapping it back-and-forth.

Cables, Grommets, and Cable Remove/Install Tool:

EW-SD50 Cables: These cables connect the front A junction, the battery, the front derailleur, and the rear derailleur to the rear B junction, which is typically located near the bottom bracket (near the cranks.) These are available in lengths of 300mm, 350mm, 400mm, 500mm, 550mm, 600mm, 700mm, 750mm, 950mm, 1000mm, 1200mm, 1400mm.

SM-GM01 Grommet: These round grommets are used when drilling round holes for internal cable routing, or with existing round holes. The required hole diameter is 6mm (6mm = .236 inches. Use a 7/32-inch drill bit and then “wallow-out” the hole to make it a little bigger; a 1/4-inch drill bit will work but is just slightly larger than necessary.)

SM-GM02 Grommet: These 7mm x 8mm oval shape grommets are used in some situations / frame designs.

Shimano TL-EW02 Ultegra DI2 E-Tube Tool: This tool is used to connect and disconnect the Etube wires. They are extremely difficult to connect/disconnect by hand, and pliers or other tools can damage the wires. Don’t get this confused with the TL-EW01 tool, which is for the older 5-wire 7970 cables. (My Dura-Ace TT Dual Control Levers came with one of these tools, but no other components did.)

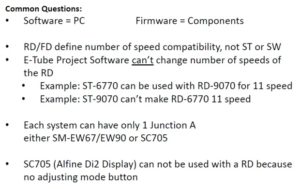

Common Questions (via Shimano):

Note: it is not necessary to replace the FD from upgrading from 10-speed to 11-speed.

What Components do I need to put together my own Di2 system?

Because of the huge number and variety of components, it’s very difficult to figure out what is actually necessary and what is optional. So here is a list, for the setup I recommend: Ultegra 6870. It starts from the handlebars and works backwards. (This assumes both front and rear derailleurs, but you actually don’t have to have both; you can pick one or the other and only the corresponding front shifter to go along with it.)

- Any Type of Shifters / Shift Buttons. The Dual Control Brake Levers/Shifters are not required. You can get the just the climbing shifters or Triathlon/TT bar-end shifters, and then potentially add the Dual Control Levers/Shifters at a later point. (The only exception is the Sprint shifters, which require specific Dual Control Levers/Shifters with special ports as noted elsewhere in this article.) Amazon.com link

- EW-SD50 Wires 1 and 2 between the front shifters and the Front Junction A (0nly for some shifters). This is a bit confusing, because some of the front shifters come with wiring attached to them and some of them require purchasing separate wires. In general, most of the stand-alone shifters come with wiring, as do the TT/Triathlon dual control shifters/levers, but the road dual control levers do not. Amazon.com link

- Front Junction A. I recommend the SM-EW90-B 5-port front junction A as it provides the most upgrade flexibility; get the 3-port option only if you’re positive you’re never going to add more shifting components. The older SM-EW67-A-E has 2 wires built-in to connect with each of the dual control shift/brake levers; it doesn’t offer much flexibility or compatibility with a TT/Triathlon setup or adding additional shifters. Amazon.com link

- EW-SD50 Wire 3 between the Front Junction A and the 4-port Rear Junction B connector. Amazon.com link

- EW-SD50 Wire 4 between the Rear Junction B and the Front Derailleur. Amazon.com link

- EW-SD50 Wire 5 between the Rear Junction B and the Battery. Amazon.com link

- EW-SD50 Wire 6 between the Rear Junction B and the Rear Derailleur. Amazon.com link

- Rear Junction B: This is where the wire from the front of the bike is connected to 3 output wires leading to the front derailleur, rear derailleur, and battery. SM-JC40 is for external wiring, SM-JC41 is for internal. Amazon.com link

- Grommets for any place where the wire goes into the frame through a drilled hole. Amazon.com link

- Front Derailleur. I recommend the Ultegra FD-6870 for 11-speed builds or the FD-6770 for 10-speed builds. The Dura-Ace FD-9070 is pretty much identical, just slightly (41g) lighter and 11-speed only. (I do not recommend the Ultegra FD-6770 unless you have a 10-speed setup, because of firmware compatibility issues with 11-speed rear derailleurs. Also, it is an older design than the FD-6870, so it is larger and offers slightly less shifting force.) Amazon.com link

- Battery and Charger. Internal or external, depending on the build. If you have to skill/time/money-to-pay-someone to get everything internal, I highly recommend that option. The SM-BTR2 internal battery has more advanced integrated electronics and is better for firmware upgrades with the SM-BCR2 internal battery charger/PC tool. If you go with the SM-BTR1 external battery, you will need the SM-BMR1 external battery mount and SM-BCR1 external battery charger. Amazon.com link

- Rear Derailleur. I recommend the Ultegra RD-6870 for a new build if you have 11-speed compatible wheels with 11-speed sprockets, or the Ultegra RD-6770 if you have 10-speed wheels/sprockets. The system must be match front and rear derailleurs (both 6870 11-speed or both 6770 10-speed.) Amazon.com link

- TL-EW02 Etube Wire Remove/Install Tool: It takes quite a bit of force to snap the wires in/out. You may think you can get it seated properly with just your fingers, only to then have the wire come loose because it wasn’t fully seated. It’s a good idea to keep one in your saddle bag. Amazon.com link

What wire lengths do I need? This question is impossible to answer correctly, as it’s highly dependent on the frame size and configuration. What I recommend is running string between the component mounting locations to measure the lengths. Be sure to add some extra length, as I find that wires seem to come up short pretty frequently, even when “adding a little extra” to start with. Nothing is more frustrating that having a wire that is 25mm too short. I recommend ordering a few extra wires of multiple lengths and then returning the unneeded/unused wires. As noted above, the standard wire lengths are 300mm, 350mm, 400mm, 500mm, 550mm, 600mm, 700mm, 750mm, 950mm, 1000mm, 1200mm, 1400mm. Do not cut/splice these wires; the connectors on the end of the wires are very small in diameter to start with and you’ll end up with a splice that is larger and less waterproof than you started with.

Acknowledgements: Special thanks to Di2diy for his continued help in the comments. Check out his Ebay store for custom Di2 batteries, harnesses, and components.

Technical Details of the Di2 CANBUS protocol and signaling

Thanks to commenter Ghislain for the details: “I reversed engineered the signal going to the RD. Since I did not have a special tap connector, I could only look at the actual signals in open loop (RD wire disconnected) on the wire going to the RD using an oscilloscope. First, I found that shift up and down are multiplexed on the same wire. A shift down would generate a positive 100 msec clean 8 volt pulse (varies between 50 msec to 500 msec depending on how long you hold the shifter). On the same wire, a shift up would generate a series of 2 msec pulses that would last the same time of a shift down pulse. Therefore, the RD has enough intelligence to discriminate between the 2 types of pulses. When you hold the button on junction A, a 140 msec pulse is generated. But since my RD wire was disconnected, the RD would not go in adjust mode.”

Hi Carlton:

I have the Ultegra 6870 groupset. In the rear derailleur trim adjustment, there are 33 positions, instead of 31. They go from -16 to 16. I have a Zipp 202 Firecrest wheelset with a Shimano Ultegra 11-28 11-speed cassette. When the Di2 is in the RD trim adjustment mode, the point in which the RD makes a slight clicking noise when it moves inward near the 4th sprocket is the 14th position, which meant i can only move the RD outside by only two steps, instead of the recommended four. Have you ever experienced this? Is it possible that the RD cage is bent inward?

Thanks!

I’ve had this same situation when the rear derailleur hanger was out of alignment. Get a Rd hanger alignment tool and realign it.

Hangers have to fit to the frame very accurately, thous out at the hanger will knock any RD out. Paint on the frame should be careful scratched off to achieve a metal to metal contact.

On my Trek Madone 5.2 I run a shimano ultegra 6770 10 speed group.

When I try to adjust my rearderailler and set the chain to the biggest sprocket and the big chainwheel in front the cheen jumps automaticaly to the smaal chainring in the front. I tried adjusting both deraillers but that does not seem to help. Does somebody know what could’t be the problem.

HI, I have just purchased a second hand bike with Dura ace DI2. On my first ride when moving into the lowest gear the crank would manage a couple of revolutions before the chain jumped down up a gear? I have tried tuning the set-up and it runs up and down the cassette fine until when in lowest gear it seems to have a mind of its own and wants to jump gear?

Help!

If you look on the E-TUBE compatibility chart,

http://e-tubeproject.shimano.com/pdf/HM-CC.2.11.1-01-EN.pdf

there is a section labeled ST / SW. I was curious what this stands for.

Thanks

ST = STI Levers

SW = Switch

Hi. I recently bought a Giant Propel Advanced bike with Ultergra di2. Everything was perfect for the first 300 miles or so. I was amazed at the pure silence and smoothness of the ride with perfect shifting. However recently a really annoying clicking noise has developed. I have narrowed this down so that it only occurs when in the big chain ring and cogs 2-6 on the rear cassette. As it is my good bike I initially left it with Chain reaction cycles for them to take a look. They said they made marginal adjustment to the hanger, ran it through the computer software, greased the pedals and made a slight index adjustment to the high and low screws. I was in a rush upon collection and didn’t try until I got home. Same issue is there only not quite as noisy. I’ve since followed the shimano di2 manual and indexed the gears exactly as stated i.e. put in 5th cog on cassetter and manually adjust derailleur until it starts to rub on the 4th cog then click 4 times to move it closer to the 5th cog etc. I’ve also perfected the high and low screws for both front and back derailleurs but I’ve still got the same problem.

Could this be the auto trim function on the front derailleur? I’ve noticed that it doesn’t auto trim until around the 6th cog on rear cassette. I’m out of ideas and the annoying thing is that this clicking noise occurs in the gears I use most. Any help would be greatly appreciated

dont know if it is actually a Di2 issue, I have had the same problem with the clicking sound in the big ring, but it was due to the BB30 bearing on the way out. Not sure if the Propel is the same BB set, but worth a mention

Thanks for responding Malcom. The bike is brand new. 350 miles so far. Has only been out on dry days with the odd occasional light rain shower. The bottom bracket should still be in great working order in my opinion. The chain reaction guy said he had the cranks off to look at the bottom bracket and said it looked fine. Although whether he did or not is up for debate!

Hi Paul,

If your Ultegra is set up correctly it should be silky smooth and whisper quiet.

I have addressed and resolved this issue before. Without seeing your set up it is difficult to address. However, I resolved one bike by correcting the chainline. With Shimano’s super narrow HG design it is important that the chainline is ‘normal’. Check out Park Tool’s discussion here for help: http://www.parktool.com/blog/repair-help/chainline-concepts#article-section-1

If it is not the chainline, you are in the right place to get great advice. Carlton and the guys here will help, doubtless.

Hi James

Thanks very much for your reply. I read the parktool article. As my bike is new I’d hope that Giant would have built it with rear and front gears following a consistent chain line. Nothing has been updated since I purchased it, that should effect this. It’s strange that the noise seemed to come after it running so smoothly. I only take this bike out in good weather and it’s had no accidents, or hasn’t fallen over etc. The only thing I can think of is that Chain reaction shop said that the firmware for the front derailleur required updating. However I suppose the noise occurred before they updated this so highly unlikely this would be the cause. It’s an 11 speed cassette so pedaling in the big chain ring in gear 5 or 6 would normally be ok as the chain shouldn’t have that much of an angle between front and rear gears. I’ve had a look at it on the workstand and can’t see that there is any chain rub in any gear combination on the front derailleur. I’ve checked the chain for stiff links also. I feel I may have to leave it into a local bike shop (a different one most likely as chain reaction guys didn’t fix it properly). The chain is a KMC on a fully shimano setup. I wonder would an shimano Ultegra 11 speed chain have any impact. I’m trying to work this out myself to cut down on costs but it looks like I’ll have to leave it with someone with a lot more expertise than me 🙁

Thanks again for your response

Hi Paul,

We will assume your chain is good. Without viewing the bike it sounds like a simple indexing issue.

Shimano’s guidance on indexing is not sacrosanct. Indexing is an ‘art’. Taking an Occam’s Razor approach, carefully re-index. Examples are not uncommon where double indexing solves issues. Viz., index in the 5th ring and then index in the 2nd ring [large not small cog]. Index to silence so that there is no ‘clicking’ or friction noise [assuming your chain is lubed and good]. Return to the 5th to check you are still without issues and quiet.

Some guys like oily chains but I am a minimalist in this area. It is not necessary to lube the outer plates of your chain. That should be cleaned off completely, unless you love gunk. The INNERS of the rollers/pins are the only areas you need to lube. Completely clean the excess off and you should be good to go.

Keep going, you will resolve this in due course.

James

Just a quick response to thank you for all your help regarding my di2 issue. I’ve now resolved using the method you’ve suggested. You were a great help. Take care

Paul

Hi Paul,

It is odd the you are getting feedback and yet you cannot see any contact when viewing the bike in your stand.

The guys here are a fountain of knowledge and will help you, gladly.

What size is your cassette?

Are you running a short or medium cage?

Does the ‘clicking’ appear only under load?

What wheelset are you running?

Have you checked the rear mech hanger?

I can recall a job we had in [not chainlink] and the ‘noise’ was a spoke issue on a zip 303 on an Evo Di2 frameset! It took some time to isolate it and when riding the sound was difficult to isolate. Eventually we nailed it.

It is doubtful that your local bike shop will give the attention to your bike that you would yourself. My advice is that you persevere here. The ‘brains’ here will help you isolate the issue in due course. Save your money.

We LOVE Di2!

James

My cassette is 11speed 11-28t. I’ve no idea whether my cage is short or medium sorry. I’m reasonably new to bikes in general. How can I tell or do I need to check bike spec on seller’s site? The clicking appears on the stand and not just under load when I’m on the bike. There is no visible sign of any rub on the front derailleur. This suggests to me that it must be rubbing slightly on the rear cassette or jockey wheels. I must have a closer look later. I’ve followed the indexing instructions from the shimano dealership manual i.e. start in 5th cog and adjust until slight rubbing on 4th cog, then click gear lever 4 times to bring back towards 5th cog. Maybe I have to experiment with more click adjustments towards the 5th cog?? My wheels are the standard giant SL1 Aero wheel system that came with the propel advanced 0 2016 model. My bike shop told me over the phone that they made a minor adjustment to the rear mech hanger but I don’t own an alignment tool so I can’t verify. I apologise if I’ve not quite explained this using the correct terminology but I’m new to all this :). When my di2 was working well I was extremely impressed with it.

Just to add a further comment. When I put my the bike in the small cog at the back and small chain ring and spin the back wheel backwards (so I don’t have to use pedals to watch the chain move) the chain looks like it slightly brushes the next cog up (bigger) then nestles back down onto the small cog again. It’s not a drastic movement but it’s there all the same. Maybe this is normal as this is not a gear recommended to use? I also recently changed from regular bike degreaser to an engine oil degreaser. Forgive me if this sounds stupid but could this degreaser cause the outer layer of the chain to become less lubricated than standard bike degreaser. I usually degrease once a week after a long ride and re lube immediately after. Possibly a silly question but from reading other posts noises can come from such a variety of situations. Thanks again for your help and advice so far

Paul

Hi, I wonder if it’s possible to tune the FD to require a 2 second push to change – especially from the small ring to the large? Sometimes in the heat of a hard climb the FD will go onto the big ring inadvertently, only a touch moving from the climbers position to the levers sometimes does this.

Hi David. The Di2 levers do not allow for a 2 second push. You can adjust the ‘speed’ of the RD shifting but programming a 2 second delay to the levers cannot be done currently.

However, you may wish to do some maintenance on your lever assembly [ http://si.shimano.com/php/download.php?file=pdf/dm/DM-DA0001-08-ENG.pdf ]. It is possible to adjust the springs on the buttons. But be careful. If your levers have seen heavy use this may help.

It is also possible [theoretically] to install heavier springs using a third-party producer. This will void your warranty and may create more problems than it solves. Shimano, as far as I know do not offer heavier springs.

The issue looks like a ‘user problem’.

Hope this helps.

Hi James, thanks for that – I don’t think I want to get into trying stronger springs. However it does occur to me that there may be some advantage in swapping the functionality of switches X and Y. This would mean the up shift would be from the smaller switch which is not so easily nudged? Easy to do. What do you think? David

Hi all

Love this site and thread….question…I have 6770 fd and rd with ext. batt…I upgraded to 11spd shifters and got the PAVE climbing shifter….plugged into the right shifter and the climbing shifter doesn’t respond…..isn’t it supposed to?….my junction A is the standard with built in wiring…I have a 3 port but not yet installed….thanks to all contributions in advance.

I believe you have to run the 3 or 5 port junction box to use the satellite shifters

Assuming your shifters are new/okay and you are using the SM-EW67-A-E Ultegra 3-Cable Junction, simply update all the firmware on all your components and it should all ‘talk’ and work fine.

If you are running the SM-EW67-A-E Ultegra 3-Cable Junction you do not need the SM-EW90-A 3-port.

I have a st7970 that was working fine but not anymore. Its jumps gears, lose adjustment and many other things… I noticed that problems are in phase with a possible error message on the leds. Both leds flash 5 times in red. Someone knows the meaning of that flashing?

Your rear derailleur has failed.

Hi Carlton,

I have a 7970 that used to be working fine. It now skips gears and is impossible to adjust. I adjust it and it changes the adjustment itself a few second after I exit the adjustment mode. When it does that, it also flashes the 2 leds in red five times. Do you know the meaning of the 5 red flashes? This also occurs when I am shifting gears and even during recovery mode. I would also get the same 5 flashes when I reconnect the 5 wire cable to the junction A.

As I said in my previous reply, these are all symptoms that the servos are about to fail. However this time you gave more information, and if you can get it to go into recovery mode indicates it is possible that junction A is at fault. But typically the symptoms indicate the RD has failed.

Thanks Di2diy. I was looking on the web to find that RD… it seems to be backorder everywhere. Do you know where I can find one?

They are on ebay. Before buying a RD I would first be sure it’s not the EW79a junction box, big difference in price

How can I make sure that it is not the junction box A? Any test to suggest? Not too many offers on Ebay these days for 7970 beside buying the full kit $$$.

Try Crosslakesales.com. (Cross Lake Sales). EW-79A for $99.99

Before buying a potential fix, I decided to do some tests. I reversed engineer the signal going to the RD. Since I did not have a special tap connector, I could only look at the actual signals in open loop (RD wire disconnected) on the wire going to the RD using an oscilloscope. First, I found that shift up and down are multiplex on the same wire. A shift down would generate a positive 100 msec clean 8 volt pulse (vary between 50 msec to 500 msec depending on how long you hold the shifter). On the same wire, a shift up would generate a serie of 2 msec pulses that would last the same time of a shift down pulse. Therefore, the RD has enough intelligence to discriminate between the 2 types of pulses. When you hold the button on junction A, a 140 msec pulse is generated. But since my RD wire was disconnected, the RD would not go in adjust mode. I kept looking at my shift up and down pluses and after a while I started to see “defectives” pulses. There is a good chance that those defective pluses are the cause of my problem. Since the RD wire is not connected when it happen, the problem is most likely in the junction box A. So, I will try to get a new junction box A… but I might also open mine to see if I could find something wrong inside.

Good work on troubleshooting the problem. I would agree it’s likely the junction. The symptoms you described are all consistent with the RD failure, except you said you could get it in recovery mode, which is not consistent with RD failure, but points to the junction. Ebay you could get a used one for cheep. If you have trouble let me know I think I have one sitting around I could sell.

Hi Ghislain, there is any chance to speak with you? I’m working on a “home made” di2, buying only the rear derailler.

I’m using a microcontroller to do the PWM modulation but I don’t have any Di2 groupset so I can’t test it properly and I would like to know the differents signals for the different functions.

Sorry if my english is…

Hi, I am trying to do the same. My own “control unit” giving orders to Shimano DI2 rear derailleur. Could we get in touch to discuss the Signal going to rear derailleur? Thank you so much!

Best regards

Thanks for the offer Di2Diy, I got a new one on ebay today. I figured that 65$ was an acceptable price.

let me know how it turns out.

While waiting to get my junction box A, I did some more tests. In fact I managed to probe the signal live when the wires were connected to the rear derailleur. That way I proved that the ghost shifting were not triggered by any signal on the usual shift up or down wire. In fact, it was obvious that ghost shifting was triggered by the activity on the fourth wire (other than power, ground and shift). That forth wire is a communication wire and this is where you find the 140 msec pulse when you turn on the adjustment mode. When the derailleur does not behave as expected, you can see a lot a communication between the derailleur and the junction A. Somehow, the derailleur is telling junction A that it was not able to perform the expected shift up and down and junction A gives it other wired recovery instructions. So after that test I was pretty sure that the new junction A would not fix my issue… and it did not. I bought a new derailleur on ebay that I got last night. I installed it and it works perfectly. Therefore, when we get the error message where the 2 red lights flashe 5 times, the solution is to replace the rear derailleur. I still have some hope to repair the faulty derailleur but before opening it I will try to see if there is any way to have it replace by Shimano… after all, it is only a few months outside of the warranty… I am working with a local store for this.

I suggested the junction was in error because I thought you said that you could get the RD to go in recovery. Also the cost of a RD is worth the chance. I do not have a scope to do the diagnostic you did. Your original symptoms did suggest it was the RD. Cheers.

Yes, it could go in recovery mode but sometime it would be partial… not going thought all the gears. As you say, junction A was cheap and can be resold on ebay anyway.

I downloaded and installed the v 2.11.1 update and now I get an E-Tube Project has stopped working error every time I try to open the app. I have Windows 10 installed. The device manager also says the driver for the SM-BCR2 is missing.

Everything worked fine before the update was installed.

I have the same issue with v3.2.2. No devices attached, just installed the software.

Solicit help from di2 gurus:

Problem: After 19 hours on SM-BCR2 charger the charging LED continues blinking once every 3 seconds. When either of 2 FD switches is depressed, the red LED on SM-EW90-A junction box blinks 5 times.

Additional, pertinent details:

-FD got stuck on small ring and stopped shifting during normal ride. RD remained fully functional. Shimano 6770 manual diagnosed low battery charge.

-Charge-error light on charger remains OFF.

-Bike is a Specialized Roubaix, purchased end of 2015; accumulated 300 miles.

-Never ridden in rain, always safely garaged and never dropped.

Should battery not have fully charged after 3 hours plugged into mains? I am now wondering whether I was better off without the Fly-by-wire gizmo 🙂

Thanks

That charger runs on USB power. It needs a USB source that’s greater than 1 amp. Make sure your USB transformer meets that spec. Many do not. This assumes all firmware is up to date. Note that most laptop USB ports meet the 1 amp spec.

Elated, Bob Goodman.

Swapped USB adaptor.

Worrisome blinking LED is a steady, yellow glow now.

Knew there was hope for the wicked.

Wicked will stay up three hours into midnight tonight – just to be sure all’s OK 🙂

Thank you.

Is there any update on allowing USB charger to charge external battery? Article seems to imply it is only external charger. Bike shop thought USB did but when tried at home it wouldn’t charge. I had to go external battery on a new Di2 compatible frame as the frame is sealed internally preventing wire running to an internal battery – thanks Bianchi! Other than drilling a hole (and voiding my warranty) now have latest external mount and Ultegra junction box. USB is a pref so can do firmware updates as well.

Hi,

I’m having a really weird issue with my di2. When I go for a ride, after 10 minutes it stops working. I hold the shifter button to see if the junction box light goes green but nothing at all. I also hold the recovery mode button for 5 seconds but nothing. At the begining I thought it was just that the battery was drained. But when I put it to charge I could see that the battery was fully charged already! The funny thing is that after plugging unplugging the charging cable everything worked fine again. Holding the shifter button showed the green light in the junction box for 2 seconds (battery 100% charged). So I went again for a ride and after 10 mins…. same thing, di2 stops working. I took it to my LBS and ran the diagnostic tool. No issues found, they just found that the internal battery was not seating correctly. We thought that could ve the issue. But again same issue whenever I go for a ride. No idea of what to do!

Could be the junction box? Battery? Any loose cables? My LBS checked all of that. What should I do now? Perhaps someone has experienced the same issue.

Thanks

Alex

I had also problems with my Di2. Check all cables if there is no break in a cable.

My system had a break in the cable running from left shifter to the junctionbox.

Hello. I have an older full Dura-Ace (7970) road kit and my rear derailleur just stop working and is not fixable. I have been trying to get just the derailleur but they are not longer available, they come once in a while in Ebay but there is none now.

Do I have any other options?

Unfortunately, you only have 2 options: wait for a used version on eBay or similar site…or upgrade everything to 11-speed Di2 (which is much more expensive and complicated.)

Got the same dilemma with my own 7970 set, although my rd is still operating fine at the moment, but am wondering which way to turn should the rd fail. Its failed once before but was ever so lucky in having a great LBS who sent it back to Shimano and almost unbelievably received a brand new one under their 3 year warranty for Dura Ace products. I say unbelievably as this was on a second hand bike, but Shimano still honoured the warranty due to the relationship the LBS had with them. I’m sure yours is probably out of the 3 year term but worth a shot with any high profile LBS in the States?(I’m from the UK by the way)

As Carlton has already pointed out, you could possibly wait for one to come up on ebay, which they do, but you could be waiting a long time.

My own personal advice to you, which is the way I am sure I will go, is to bite the bullet, rip your Dura Ace set out, sell the working parts left and put towards an Ultegra 6870 11speed upgrade kit. The link below for an Internal kit on ebay in the States is going for around $1,000. You will need a cassette and chain on top of this though. One thing also to remember is that the Ultegra cable is approx 1mm smaller than the 7970 cable, which may or may not affect anything when installing

(http://www.ebay.co.uk/itm/2016-Shimano-Ultegra-6870-Di2-Electronic-11s-Group-Groupset-Kit-INTERNAL-/161960521345?hash=item25b5996e81:g:UMsAAOxyVaBSt5mU)

You don’t necessarily need to change your 10 speed crankset at the moment as this will work more than satisfactorily with an 11 speed chain/system.

You can stop worrying then for the moment about anything failing as the parts for the 6870 group will be available for many years to come.(until 12 speed incompatible sets ease their way in!).

If you are handy on your bike and can do the conversion yourself, the following install might be of some general use to you, which is one I did for my son’s Scott a few years ago. Slightly different scenario in that he had 10 speed mechanical and wanted to go Di2 and I fitted the battery externally, not an internal seatpost type

(http://weightweenies.starbike.com/forum/viewtopic.php?f=2&t=130944)

The difference between Ultegra and Dura Ace is not that great and certainly not worth the mega price difference.

Best of luck whichever way you go!

Re my last post, sorry, this was the link to the Di2 install I was talking about.

(http://weightweenies.starbike.com/forum/viewtopic.php?f=10&t=101676&p=1132070&hilit=white+Scott+Foil+U+Di2#p1132070)

Hello, be patient and you will find one on Ebay. I just bought a new one earlier this week and I see 2 used ones available right now… One of the auction ends 7 hours…

Hi Carlton,

I’m building a test platform that is goin to use the gear shifting system shimano DI2 6870 but we want to replace the battery by a voltage source. So we are wondering if you know the input voltage required for the external mount of the SM-SMBTR1 battery or battery pinout polarity.

Thank you in advance,

Ricardo.

It is about 9V (near full charge) and negative is closest to the mount side that the battery slots on.

Hi All,

I have just worked out a hack to downgrade software using the E-tube software. Let me know if you want more info on how to do this. Perhaps it would be useful to add it to this page. Of course someone probably has worked it out before, so it may be that this is nothing new.

I did this using etube 2.11.0 but it probably works with the latest. I just installed 2.2.3 off the etube site (for older OS) and got the old firmware files from it tricked the newer etube into thinking they were newer files than installed on my bike.

In my case I used it to downgrade an internal battery and shifters to enable me to use an internal battery with the EW67 junction. Bike working great!

@Vosadrain – I didn’t know downgrades were possible. Yes, please share the details. I assumed there was a certain level of file validation through headers or checksums. It sounds like that’s not the case and that it’s at the file name level. Thanks for sharing the info.

Shimano have done little to prevent you hacking it. I am no hacker. Just trying to upgrade my wife’s bike to internal battery and 11 speed from an older 6770 setup like I did on mine about 2 years ago. Unfortunately firmwares had progressed since 2 years ago so it did not work. I ended up having to downgrade shifters and battery to get it to work.

Unfortunately many older Etube versions you link to here are not valid links. I have a copy of 2.11.0 and downloaded 2.2.3. I think this would work with the two downloadable versions. I installed 2.2.3 and made a copy of “C:\ProgramData\E-tube Project\FW” which has all the firmwares packaged in that version of etube. I then installed the later version (2.11.0, but will probably work with the latest version). Then copy all the firmwares from the the 2.2.3 version back to the same location “C:\ProgramData\E-tube Project\FW”. Now the trick is to find the firmware you want to downgrade (pretty easy from the name and version in the file name), and then rename it to the same name as the latest version, but increment the last version digit by one. Then connect with etube (without internet connection) and it will identify that a firmware upgrade is available for that component and allow you to do the firmware upgrade. Do the upgrade and exit etube and then rename the firmware file back to original to prevent issue in future. Etube will then try to upgrade again but just don’t let it do that.

I was able to get a bike that did nothing (not even enter adjustment mode) to fully working by reverting the battery and shifters. I am still running latest firmware in derailers and that seems fine.

Now I would really like to find a copy of Etube 2.5.2. 2.2.3 is pre 6870 I believe so will not connect to my bike. I would like to load the latest firmwares to all my components to make them 2.5.2 level. Has anyone got a copy I can get from somewhere?

Yes its is possible to downgrade, the firmware… but if the BCR2 was previously upgraded you will not be able to charge the BTR2 battery. There is an even easier solution, buy one of my internal seatpost battery kits and not have to go through all that hacking. my kit makes it possible to run you all the components with the current etube firmware. Also worth noting some of the updates were done to fix power distribution errors in the FPGA’s that would allow the batteries to drain down when the bike was just sitting. http://www.ebay.com/itm/291752577324?ssPageName=STRK:MESELX:IT&_trksid=p3984.m1555.l2649

Did you know this hack was possible?

Well mine is charging just fine. I might have an older BCR2 (got it about 2 years ago). I never really upgrade anything unless I have a reason to (and typically use Etube with the internet disconnected). I also note that the BCR2 firmwares are in the location C:\ProgramData\E-tube Project\FW and I have an older one from 2.2.3. It is quite likely you could downgrade the BCR2 in the same way as the other components, but I have not tried this and have no reason to.

Your kit is probably a good option for some. In my case I payed under US$100 for a BTR2 and already had a BCR2 and was able to get it working with an hour or so of hacking etube.

Note that this hack will also be of use to those wanting to run mixed 10/11 speed setups as they can buy a new 11 speed part and revert the firmware to enable it to work with their existing 10 speed parts.

Someone must have a copy sitting on a PC somewhere. It would be great to have, as with this hack, it would enable people to revert parts manufactured today to the latest version before Etube locked out mixed setups.

I found my copy of 2.5.2. The post has been updated with instructions and 2.5.2 download links, but having issues getting the file on the server and assigning correct download permissions. I’ll get it fixed soon.

Thanks Carlton. The new additions to the page look good and should help some people out. Unfortunately I cannot get access to the Etube 2.5.2 link. Do I need to register or something to use that link you added to your internal uploads section? I just get redirected to “Oops not found”.

Hi Carlton,

Just noting that the link you provided to Etube 2.5.2 does not seem to work for me. Would be great to get a copy if you have it sitting on your server, but I cannot get to it at the moment.

Cheers,

Adrian

but have you tried to charge the battery?

I just connected it up for charging and it is charging fine. Have you done this before and had issues with charging?

In my case I have my bike I did 2 years ago and my wifes bike this last weekend. Both were originally 6770. On both I upgraded the battery and derailers, but not the shifters or junction. With the old EW67 junction there is no place to plug in the BCR2 charger, so I made a BCR2 to DI2 connector adapter from a spare DI2 cable I chopped up. Using that I either connect to a spare port on the shifter, or I use another spare cable and a BB junction to connect in line at the EW67 junction connector (this is easier than pulling back the hoods). Using this arrangement I am able to charge the batteries in both and also do any programming I need to do.

Note however that late etube software says my setup is unsupported and does not let me do anything. If I want to do programming I have to disconnect the internal battery and connect a spare external battery I have to turn into a supported setup and then I can change settings etc. This takes about 30 seconds as I just pull the BB junction out through the bottom and make the necessary connection changes to connect it to my old BTR1. When I want to program the BTR2 itself, I just connect to the BTR2 by itself (no other components) and the Etube software will allow me to do firmware changes to it. For me it is worth keeping an older BTR2 handy so I can make my setup “recognised” to do anything I want to do. Having said that, I never use etube except then changing the Di2 setup on a bike. I have no reason to connect to it unless it is not working, so these bikes will probably never connect to Etube again until the next time I change something on the setup.

Looking to put 6870 on my cross bike but want to be able to swap to an Ultegra road compact crankset during the summer. Is this an easy thing to do? Assuming I just need to raise/lower the FD. Would getting a GS RD help with the chain length?

You said “Nothing from the first generation (5-conductor) Dura-Ace Di2 7970 system is compatible with any other system. It was replaced by the (2-conductor) E-tube systems. No parts are interoperable between them.” I have a tt bike with tt shifters. Do I also have to buy new ones?

None of the Di2 7970 10 speed including shifters is comparable with the new e tube Di2.