I learned quite a bit about Shimano Di2 when I installed one of the first available Time Trial/Triathlon groupsets on my Cervelo P2. I’ve subsequently answered a lot of questions on forums and article comments, and elsewhere. In doing so, I realized that people have a lot of questions about Di2 and the answers are difficult to find. This lead me to create this article, to consolidate everything I know and have been asked into one location so people can find answers. If you can’t find what you’re looking for below, please leave a comment and I’ll do my best to help.

I learned quite a bit about Shimano Di2 when I installed one of the first available Time Trial/Triathlon groupsets on my Cervelo P2. I’ve subsequently answered a lot of questions on forums and article comments, and elsewhere. In doing so, I realized that people have a lot of questions about Di2 and the answers are difficult to find. This lead me to create this article, to consolidate everything I know and have been asked into one location so people can find answers. If you can’t find what you’re looking for below, please leave a comment and I’ll do my best to help.

Index: There’s lots of info in this post, so here’s an Index to help you find specific sections:

- Di2 General Overview

- Compatibility: Between 6770 10-speed, 6780 11-speed, 9070 11-speed, first-gen 7970

- How to Check Battery Level

- How to Adjust Rear Derailleur Trim

- How to Adjust Front Derailleur Trim

- Dealer Installation Manuals

- Shimano E-tube Project Software – Change Settings and Update Firmware

- Chargers, PC USB Interfaces/Programmers

- Component Overviews

- Shift/Brake Levers

- Dedicated Shift Buttons

- Front Derailleurs

- Rear Derailleurs

- Display Units and ANT Bluetooth Wireless Communication Modules

- Batteries and Battery Mounts (Internal and External)

- Front Cable Connection A Junctions (with charger ports and LED status lights)

- Rear Cable Connect B Junctions

- Cables, Grommets, Cable Install Tools

- List of Components Needed to Build Your Own Di2 System

- Technical Details of the Di2 CANBUS protocol and signaling

System Overview: Shimano Di2 Dura-Ace 9150 and 9070 and Ultegra 6770 and 6870

The second generation Shimano Ultegra 6770/6870 and Dura-Ace 9070 “E-Tube” electronic bicycle shifting systems consist of battery-powered electric derailleurs activated by handlebar mounted push buttons. Power and shift commands are sent via a 2-wire CAN (Controller Area Network) datalink contained within a single cable housing. This design has several advantages over conventional mechanical shifting systems, the most notable of which are:

- Extremely low shifting effort, which generally results in more frequent shifts and therefore better gear ratio selection.

- Greatly improved shift quality, especially for the front derailleur chainrings, allowing shifting under full power with almost no chance of a dropped chain.

- Shifting is available at multiple positions on the handlebars, for example, at the end of the time trial aero bars, on the brake levers, up to in climbing position, and down low the sprint position.

- Automatic trimming of the front derailleur position as the rear derailleur moves back and forth between the smaller and bigger gears. This eliminates unintended contact (and noise) between the front derailleur and the chain.

- Lighter weight vs. equivalent mechanical system. The Shimano Dura-Ace Di2 9070 electronic groupset with internal battery weighs 2047 grams; the Shimano Dura-Ace 9000 mechanical groupset weighs 2074 grams (27 grams more than Di2.)

- Multi-Shift: Pressing and holding a rear derailleur shift button results in shifts through multiple gears. The rate of shifts can be configured using the PC computer interface cable and the free Shimano E-tube Project software.

- Synchronized Shifting: Starting with Dura-Ace 9150, automated Synchronized Sifting of the front derailleur is an option. Two SHIMANO Synchronized Shift modes will be available:

- Full SHIMANO Synchronized Shift: the front derailleur reacts based on the rear derailleur’s shift action. This essentially means that, when activated, there is no need for two separate shifters to control front and rear derailleurs, the two buttons on one shifter will control both derailleurs.

- Semi SHIMANO Synchronized Shift mode: the rear derailleur reacts based on the front derailleur’s shift action, shifting to the next most appropriate rear gear when the rider makes a front shift.

- R9120, R9170 – syncroshift enabled with firmware 3.2.0 or newer

- 6870, 9070 – syncroshift enabled with firmware 3.2.1 or newer

- 6770 – no syncroshift firmware update will be offered

Historic Info on the older first generation 5-wire Shimano Dura-Ace Di2 DA-7970 system and how it compares to the new E-tube 2-wire system:

Historic Info on the older first generation 5-wire Shimano Dura-Ace Di2 DA-7970 system and how it compares to the new E-tube 2-wire system:

Released in 2009, the 7970 operated using a very basic 5-wire electronic system. Each shift button was connected to a different wire; shorting the specific wires together controlled the derailleur upshifts and downshifts. Because the first generation 7970 used completely different technologies than the newer 2-wire systems, none of the components are cross-compatible. At this point, Shimano is not expected to offer any updates or new components using the first generation 7970 architecture; everything from now on will be based on the newer 2-wire E-tube design. The second generation design offers several advantages, which include: 1) smaller wire size, smaller connector size, waterproof connectors; 2) all switches can be reconfigured in software to send upshift or downshift commands to either the front or rear derailleur; 3) firmware updates can add new features (such as multi-shift) and compatibility with new components.

Compatibility: Dura-Ace 9070 and Ultegra 6770 / 6870 (and old 5-conducter 7970)

The confusing naming system used by Shimano makes it difficult to figure out what each component is, much less what is compatible between systems. Here are some compatibility guidelines:

- Nothing from the first generation (4-conductor / 5-conductor) Dura-Ace Di2 7970 system is compatible with any other newer system. It was replaced by the (2-conductor) E-tube systems. No parts are inter-operable between 7970 and any other Di2 System.

- In general, every electronic Di2 component is compatible between the Ultegra 6770, 6870, and Dura-Ace 9070 systems (see exceptions below.) This means that all of the road bike Ultegra/Dura-Ace dual control brake levers/shifts, time trial shifters, and climbing shifters can be used with either Ultegra 6770/6870 or Dura-Ace 9070 front and rear derailleurs. Any of the Ultegra/Dura-Ace controllers (A Junctions) can be used with either system. All components use the same cables and connectors.

- Firmware Update Required to Make Older Components Compatible with Newer Components: If you add a new component and it doesn’t work, update the firmware using the PC USB adapter and the Shimano E-tube Project Software for Windows.

- Synchronized Shifting and Bluetooth Wireless Units can be added to all E-tube Ultegra and Dura-Ace systems but the battery has to be upgraded to the BT-DN110 Internal Battery or BM-DN100 External Battery Mount. To add Bluetooth capability, a EW-WU101 or EW-WU111 inline transmitter must be added to road bikes and for mountain bikes, the SC-MT800 or SC-M9051 display/transmitter unit must be added.

- Compatibility Exceptions:

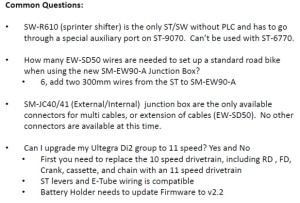

- Note 1 – Sprint Shifter Exception: The Sprint Shifter is the only exception for shifter incompatibility. It has a different wiring connector (and internal components) that can only plug into a unique/dedicated third port on the Dura-Ace ST-9070 Dual Control Brake Levers/Shifters and also the ST-6870 Levers. There is no sprint shifter port on the ST-R785 Hydraulic Levers.

- Note 2 – Can’t mix 10-speed/11-speed front/rear Derailleurs: It is no longer possible to use a 10-speed front derailleur with an 11-speed rear derailleur (and 11-speed front with 10-speed rear.) See note farther below to read the history on this if you want all the messy details.

- Note 3 – Front A junction and Internal Battery: Since the February 2015 firmware update, the older SM-EW67-A-E Front Junction A is no longer compatible with the BTR2 Internal Battery because it does not have the charging port to charge the internal battery. The SM-EW90 Front Junction (with integrated charging port) should be used instead. The SM-EW67 still works with the external battery.

- Note 4 – Update the Firmware to make components compatible: If the firmware on all components is not updated to the latest version, some components may be not operate correctly with one another. So download the latest E-tube software and update everything and it should work.

- Note 5 – All Shifters work with all 10-speed and/or 11-speed Rear Derailleurs: All of the shifters are compatible with either the 10-speed Ultegra 6770 or 11-speed Ultegra 6870/Dura-Ace 9070 systems as long as they all have the latest firmware. The rear derailleur is the only component that “knows” or “cares” how many rear gears are available. The shifters only send upshift/downshift commands and do not “know” or “care” which gear is currently selected and how many total gears there are.

- Note 6 – SM-BTR1 External Battery and SM-BMR1 Mount firmware updates: The more expensive dedicate service tool (SM-PCE1 PC Interface) must be used to upgrade the firmware on the external battery/mount.The external battery and battery mount can not receive firmware upgrades via the SM-EW90 Front Junction A and the SM-BCR2 PC Interface/Battery Charger. (The SM-EW90 will work in a system with an external battery, but a firmware update can cause them to become incompatible until both are updated independently using the appropriate PC Interface and the Shimano E-Tube Project software.)

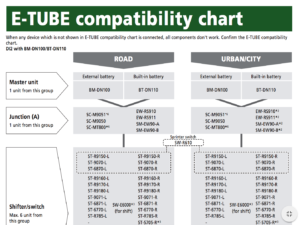

- See the Shimano E-tube compatibility chart version 3.4.3 for more details

Compatibility: 11-Speed Rear Derailleur and 10-speed sprockets/wheels

The 11-speed Dura-Ace 9070 and Ultegra 6870 rear derailleurs are designed exclusively for 11-speed rear sprockets and 11-speed Front Derailleurs. Shimano does not provide a way to recalibrate/reprogram them for a 10-speed setup. The sprocket spacing is slightly smaller and the overall range of travel slightly longer on 11-speed systems. If you have 10-speed wheels and 10-speed sprockets, you should use the 10-speed RD-6770 rear derailleur and a 10-speed FD-6770 front derailleur.

Similarly, a 10-speed RD-6770 rear derailleur should not be used with 11-speed sprockets. There will be chatter in some gears, and there might be slow-shifts or self-shifts.

It doesn’t matter which shifters are used; the shifters send upshift/downshift commands regardless of which derailleur config is being used. Shifters do not “know” or “care” which gear is currently selected and how many total gears there are.

Front Chain Rings: In general, most any front chain rings will work, rigid forged rings work best with Di2 due to high front derailleur shift forces. Shimano chain rings tend to be the best, but most others work as well. A 10-speed specific or 11-speed specific chain should be used, but the differences between them are minimal and can generally be mixed/matched without issue.

How to convert “non-upgradeable 10-speed only” wheels such as Zipp 900/Sub9 Disc Wheels to 11-speed: “the spacing between a Campy 11 and Shimano 11 is close enough that you can use the cassettes interchangeably. If you get a Campy free hub body, the 2 shims (part# is on the Zipp website, just search for Campagnolo 11) and a Campy cassette and you’re ready to ride with all 11 cogs available to use.” via slowtwitch.com

But it’s an emergency and I need to use a 10-speed wheel. . . In emergency situations, 11-speed rear derailleurs can be used with 10-speed sprockets. There will probably be chatter in some gears, and there might be slow-shifts or self-shifts. To setup an 11-speed rear derailleur for a 10-speed sprocket setup, adjust the mechanical limit screw so that it can’t shift into the missing 11th sprocket position, then follow the rear derailleur adjustment procedures listed below.

Included for very motivated individuals only: 10-speed front derailleurs can be used with 11-speed rear derailleurs if the shifters and battery have firmware installed from E-tube software version 2.5.2 or earlier. Shimano disabled support for this 11-speed and 10-speed cross-matching with later firmware updates. For informational purposes only, the details of how to regain compatibility are detailed below.

- Important Notice 2014-07-14: There is a compatibility issue with Shimano e-Tube software/firmware versions v2.6.0 and later that prevents 10-speed front derailleurs (FD-6770) from working with 11-speed rear derailleurs (RD-6870) and 11-speed front derailleurs (FD-6870) from working with 10-speed rear derailleurs (RD-6770). DO NOT UPDATE FIRMWARE using Shimano e-Tube software v2.6.0 or later if you are mixing an FD-6770 front derailleur and a RD-6870 11-speed rear derailleur, or a FD-6870 with a RD-6770.

- The problem component is the battery (external battery mounts SM-BMR1 and SM-BMR2, internal seat post battery SM-BTR2.) If you keep battery firmware at v2.0.6 or earlier, the system will continue to function properly. Shimano e-Tube Software v2.6.0 will update battery firmware to v3.0.5, and will not allow the RD-6870 to work with a FD-6770 setup.

- If the battery firmware is updated to 3.0.5, it CAN NOT be rewritten back to the older version. You will need to need to replace a derailleur so that both are 6770 10-speed or so that that both are 6870 11-speed. (The other option is to get get a battery with the older firmware and never update it.)

- Here’s a link to the “last known good version” of the Shimano e-Tube software to work with a mixed 10-speed/11-speed system: E-tube_Proj_V_2_5_2.zip Use this version and do not connect to the internet when using it so that E-tube can’t check for updates when open.

- To roll-back newer versions of battery and shifter firmware, install E-tube version 2.5.2 and made a copy of “C:\ProgramData\E-tube Project\FW” which has all the firmwares packaged in that version of E-tube. Next, install the latest version of E-tube. Then copy all the firmwares from the the 2.2.3 version back to the same location “C:\ProgramData\E-tube Project\FW” for the latest version (note: ProgramData is a hidden directory, click here for details on how to view it.). Next, the trick is to find the firmware you want to downgrade (pretty easy from the name and version in the file name), and then rename it to the same name as the latest version, but increment the last version digit by one. Then connect to the bike with E-tube (without an internet connection) and it will identify that a firmware upgrade is available for that component and allow you to do the firmware “upgrade” to the older version of firmware. Now exit E-tube and then rename the firmware file back to original to prevent the issue in future. E-tube will then try to upgrade again but just don’t let it do that. This should get a bike that did nothing (not even enter adjustment mode) to a fully working state by reverting the battery and shifters. Running latest firmware in derailleurs seems to be fine. (thanks to commenter vosadrain)

- It will not be possible to charge the BTR2 internal battery using the BCR2 USB charger unless you also downgrade the firmware of the BCR2 USB charger as well.

- Note however that latest E-tube software will say the setup is unsupported and will not allow programming. To do programming, disconnect the internal battery and connect a spare external battery. This allows making settings changes. To program the BTR2 itself, I just connect to the BTR2 by itself (no other components) and the E-tube software will allow firmware changes to it. Or try using the 2.5.2 version of E-tube.

- Alternatively, buy a Di2DIY internal seat post battery kit and you will not have to go through the firmware downgrading. The kit makes it possible to run all components with the latest E-tube firmware. Also worth noting some firmware updates were done to fix power distribution errors in the FPGA’s that would allow the batteries to drain down when the bike was just sitting.

Checking Battery Charge Level:

A single battery charge should give at least 1500 miles of riding. Most riders will not need to charge the battery more than twice a year.

To check the battery charge remaining, press and hold any shifting switch for 0.5 seconds or more. The amount of battery charge remaining will be indicated by the light on Front Controller A Junction.

- 100% remaining: Illuminates green (for 2 seconds)

- 50% remaining: Flashes green (5 times)

- 25% remaining: Illuminates red (for 2 seconds)

- 0% remaining: Flashes red (5 times)

When the battery charge is low, first the front derailleur will stop operating, and then the rear derailleur will stop operating. When the battery charge has been fully spent, the derailleurs will be fixed at the last gear shifting position. If the battery indicator is illuminated red, it is recommended that you recharge the battery as soon as possible.

Adjusting the Rear Derailleur Trim:

If you switch between multiple rear wheels, it’s very likely that the sprockets on different wheels won’t be in exactly the same relative position to the rear derailleur, resulting in that annoying clicking sound as the chain makes contact with an adjacent sprocket. Follow the steps below to properly align the rear derailleur with the rear sprockets.

- Shift the rear derailleur to the 5th sprocket position. Press the button at the junction (A) of the SM-EW67-A-E until the red LED illuminates in order to switch to rear derailleur adjustment mode. Note that if you keep pressing the button after the red LED has illuminated, protection recovery operation will begin.

- If shifting switch is pressed once while the initial setting condition is active, the guide pulley will move one step toward the inside. If shifting switch (Y) is pressed once, the guide pulley will move one step toward the outside.

- Note: The guide pulley can move 15 steps inward and 15 steps outward from the initial position, for a total of 31 positions.

- Note: When adjusting, the guide pulley will overrun slightly and then move back in an exaggerated movement so that you can check the adjustment direction. When checking the positions of the guide pulley and the sprocket, check at the position where the guide pulley finally stops.

- While turning the front chainwheel, operate shifting switch to move the guide pulley toward the inside until the chain touches the 4th sprocket and makes a slight noise.

- Next, operate shifting switch 4 times to move the guide pulley toward the outside by 4 steps to the target position.

- Press the button at junction (A) until the red LED turns off in order to switch from rear derailleur adjustment mode to gear shifting mode. Shift to each gear and check that no noise is generated at any gear position. If fine adjustment is needed, switch back to adjustment mode and readjust the rear derailleur.

- Note: if you have customized your shifters and swapped buttons, this will change which shifter and buttons control the micro-adjustments. Also, if you hit the wrong buttons while trying to set the FD trim, you can actually alter the setup of your RD. Be certain that you’re hitting the correct adjustment buttons.

- If you have a Garmin or similar head unit and a SM-EWW01 ANT module, the display will automatically switch into derailleur trim display when you activate that mode (i.e. by pressing the button at the junction (A) of the SM-EW67-A-E.) It will give you the trim position in either + or – 12 positions. When switching wheels, simply take note which position suits which wheel/sprocket/trainer, and trim to that level each time you change. This removes the guesswork and makes changing from wheel to trainer simple.

Note on FD-6870 Front Derailleur Trim:

The FD-6870 trim adjustment effects the auto-trim positions. The adjustment feature is accessible via either the A-Junction box, or the “Front derailleur adjustment setting” in the e-tube software, and should be used only after you have already set the physical inner/outer limit screws. So for example, if the FD outer plate rubs the chain when using the 6th largest cog, you would want to adjust the FD trim outward a couple ticks. However, you can only perform this adjustment while in the big-ring/big-cog combination. Etube forces the derailleurs into this maximum cross-chained position, whereas during the manual method you must shift to these positions yourself. (Thanks to commenter Bryan B for the info.)

Dealer Manuals:

The dealer’s manuals contain the most detailed information available from Shimano. If you’re looking for detailed installation instructions, check here:

- Shimano Ultegra 6770 Dealer’s Manual: http://techdocs.shimano.com/media/techdocs/content/cycle/SI/Ultegra/UltegraDi2/6770Di2_DM_EN_v1_m56577569830773882.pdf

- Shimano Ultegra 6870 Dealer’s Manual: http://si.shimano.com/php/download.php?file=pdf/dm/DM-UL0001-00-ENG.pdf

- Shimano Dura-Ace 9070 Dealer’s Manual: http://si.shimano.com/pdf/dm/DM-DA0001-00-ENG.pdf

- Shimano Alfine Di2: http://si.shimano.com/php/download.php?file=pdf/dm/DM-AL0001-03-ENG.pdf

Shimano E-tube Project Configuration and Firmware Update Software for Windows:

Shimano E-tube Project Wireless for iOS and Android: Announced on April 15, 2016 but as of yet unreleased, these apps will allow configuration of shift profiles (multi-shift on/off, multi-shift delay between shifts, shifter button assignments) and firmware updates over Bluetooth. To function, a Shimano Di2 Bluetooth Adapter, such as the MT800 digital display, is required.

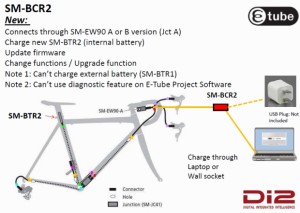

Shimano E-tube Project Windows PC Software: This free software is used to update the firmware of all components. It works with the SM-BCR2 Charger + USB Adapter and the SM-PCE1 Diagnostic Adapter. The software is used to change the configuration of each shift button / lever (any can be programmed to upshift or downshift either the front or the rear derailleur.) It can also be used to enable multi-shift (multi-shift is where the shifter is held and the rear derailleur shifts through multiple gears until the shifter is released.) The delay between of the gear changes during multi-shifting can also be adjusted. The software is available from http://e-tubeproject.shimano.com/

Older versions of the e-tube software are available from these links: 2.5.2

PC & Mobile Interfaces, Chargers, and Software:

SM-BCR1 Battery Charger: This is used to charge the external battery. The part number for the battery charger wall cord is SM-BCC1.

SM-BCR2 Charging and PC Connection: for SM-EW90-A 3-port and SM-EW90-B 5-port A Junctions. This plugs into a special port on the side of the A junctions (which is covered by a rubber flap.) This adapter charges the internal battery when first plugged into the A junction; it must be powered by a standard USB Wall charger (such as that used for an Apple iPhone) or a PC that is powered-on. If the Shimano E-Tube Project Software is launched on the Windows PC with the SM-BCR2 attached, the SM-BCR2 will switch from charging mode to configuration mode. It must be detached from the computer and reattached to switch back to charging mode.

- It takes about 2 hours to charge the internal battery.

- Amber light=charging.

- Light turns off when done.

- If the Amber light does not come on when plugged in, this indicates battery is not discharged enough to charge.

- Light flashing indicates something is wrong, like trying to charge a external battery through a BMR.

Hacking the SM-BCR2 to have a standard Di2 cable connector: If your 3-port or 5-port junction is inaccessible for charging, there is an alternative hack method to connect it to the system through a standard Di2 port. With basic soldering skills you can hack the BCR2 to be used with any setup. Buy any length EW-SD50 wire, cut off one end. Cut the wire on the output side of the BCR2. Splice the two wires together, so that the output wire of the BCR2 is now a standard Di2 connector. The charger has an inner (white) and outer (shield) wire; connect the inner white wire to the SD50 red wire; connect the charger outer shield wire to the SD50 black wire. You will then be able to plug the BCR2 into any Di2 port. Or use a SM-JC40 junction B and another length of EW-SD50 wire and go through the RD (by using the SM-JC40 to connect the rear derailleur, new output wire of the EW-SD50, and the wire that ordinarily connect the rest of the system to the rear derailleur.) Thanks to @Di2diy for the info.

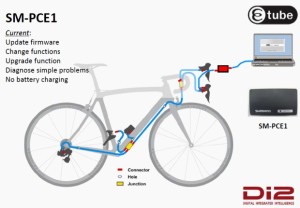

SM-PCE1: This PC Configuration and Diagnostics adapter will not charge the internal battery. It offers the same configuration options as the SM-BCR2, but also add some advanced diagnostic and troubleshooting features that the SM-BCR2 does not have. It attaches to via the standard E-tube wire (just like the EW-SD50 cables) rather than to a dedicated port on the side of the front A junction.

Bluetooth and E-tube Apps for Apple iOS and Android: Bluetooth wireless modules are available to allow system settings to be adjusted via the mobile applications that connect via Bluetooth Adapters.

Component Overview:

The confusing naming system used by Shimano makes it difficult to figure out what each component is, much less what it does and how it fits into an a complete Di2 system. Here’s an overview of all the major Ultegra and Dura-Ace Di2 components.

Dual Control Brake Levers/Shifters (a.k.a. Brifters):

ST-6770 Ultegra Road Dual Control Brake Levers/Shifters: The Ultegra version can be used with the climbing shifters. They are sold in in left/right pairs and are also available separately.

ST-9070 Dura-Ace Road Dual Control Brake Levers/Shifters: The main advantages these have over the ST-6770 version is slightly lighter weight and compatibility with the low-mount sprint shifters. As like the Ultegra version, they are compatible with the climbing shifters. They also have hidden button under the rubber hoods that can activate screen changes on cycling computers from Garmin, Magellan, Pioneer, and Shimano (Shimano SM-EWW01 ANT Wireless Broadcast Module required.)

ST-9071 Dura-Ace Time Trial/Triathlon Dual Control Brake Levers/Shifters: These levers provide shifting from the pursuit bar position on time trial bikes. There is no Ultegra option offered at this time. These are available as left/right pairs, or can be ordered separately. These do have a permanently attached wire with a male end for connection the the SM-EW90 front “A” junction. Combined weight both levers: 117 grams.

ST-R9160 (standard cable brakes) and ST-R9180 (hydraulic brakes) Time Trial Dual Control Brake Levels/Shifters: These are the lower-profile shifters offered with the newer Dura-Ace R9150 groupset.

ST-6871 Ultegra Time Trial/Triathlon Dual Control Brake Levers/Shifters: Ultegra version of the ST-9071 Dura-Ace shifters. Slightly heavier and much less expensive than the Dura-Ace version. Combined weight both levers: 142 grams.

ST-R785 Hydraulic Road Dual Control Brake Levers/Shifters: These hydraulic road shifters are compatible with both the climbing and sprint shifters. These are compatible with the SM-RT99 centerlock 140mm and 160mm rotors and WH-RX31 wheelset (which as no standard rim brake track.) These require the BR-785 dual piston hydraulic disc calipers. They do not have the special wiring port required for the SW-R610 Sprint Shifters and a SM-EW90-B 5-port junction A is required to use the SW-R600 climbing shifter.

ST-6870 Ultegra Road Dual Control Brake Levers/Shifters: These road shifters are compatible with both the climbing and sprint shifters.

Dedicated Shifters:

SW-R671 Dura-Ace 2-Button Time Trial/Triathlon Bar End Shifters: These shifters are installed on the end of time trial aero bars. By default, the left shifter upshifts/downshifts the front derailleur; the right controls the rear derailleur. For both, the lower button upshifts into a harder gear and the upper button downshifts to an easier gear. This can be changed using the Shimano E-tube Project software; the functions of the left and right sifters can be switched with one another as well. These are available in pairs or separately.

SW-9071 Dura-Ace 1-Button Time Trial/Triathlon Bar End Shifters: These shifters have only one button each and are intended to control only the rear derailleur, with one sending the upshift command and the other the downshift command. (I personally think this version is absolutely worthless. Why have 2 SW-9071 shifters at twice the price and twice the weight, when you can just buy a single SW-R671 Right shifter instead.)

SW-R600 Climbing/PAVE Shifter: This shifter is for road bikes and is mounted on the upper horizontal portion of the handlebar, or any other location comfortable for the rider. They can be used in addition to the Dual Control Brake Lever/Shifter, or can be used on their own by plugging directly into a SM-EW90-A 3-Port Junction or SM-EW90-B Dura-Ace 5-Port Junction.

SW-R610 Dura-Ace Sprint Shifter: This is the only component using a unique wiring connector; it is only compatible with the ST-9070 Dura-Ace and Ultegra ST-6870 Road Dual Control Brake Levers/Shifters. Unlike all of the other shifters, the sprint shifters do not contain a circuit board; they do not show up as components on the CAN bus network. Instead, the sprint shifters are simple momentary switches that activate the circuit board on the host Dual Control Brake Lever/Shifter. The host dual control lever is what sends the shift command. (Note: Any momentary switch can be attached to the sprint shifter port on the Dual Control Levers by splicing into a standard EW-SD50 wire to act as remote shifters.)

Alfine SW-S705 Right Flat-Bar Shifter: Reported to work with other non-Alfine setups.

SW-R9160 Time Trial bar-end shifters (pair): These are-end shifters directly control the rear derailleur, with one for the upshfit and one for the downshift. The front derailleur is controlled automatically via automatic Synchronized Shifting. These shifters require the BT-DN110 Internal Battery for synchronized shifting.

SW-R9150 Climbing shifters (pair): These tiny climbing shifters are about as small as the sprint shifters, but can be directly connected to a junction box and do not have to be connected as slave buttons to a brake/shift lever special port. They come with plastic mounts to make it easier to attach to bars beneath bar tape. They are ideal for synchronized shifting, with one controlling the upshifts and the other downshifts. These shifters require the BT-DN110 Internal Battery for synchronized shifting.

Front Derailleurs:

FD-6770: Ultegra Front Derailleur

FD-6870: Ultegra Front Derailleur, pretty much identical to the FD-6770 but with a slightly larger diameter adjusting screw (to better dissipate the shifting forces).

FD-9070: Dura-Ace Front Derailleur

FD-R9150: Dura-Ace Front Derailleur for 9150 systems; features slightly reduced weight vs. 9070.

Rear Derailleurs:

RD-6770: Ultegra 10-Speed Rear Derailleur, compatible with gears up to 28 teeth.

RD-6870: Ultegra 11-Speed Rear Derailleur, compatible with gears up to 32 teeth (for the GS version).

RD-9070: Dura-Ace 11-Speed Rear Derailleur, lighter weight version on which the RD-6870 is based.

RD-R9150: Dura-Ace 11-Speed Rear Derailleur with 30-tooth sprocket compatibility and modified “Shadow RD” geometry to keep the mechanism close to the rear wheel to help avoid damage in the event of an accident.

Alfine SG-S505 and SG-S705: The Shimano series targets comfort and urban bikes. It uses an 8-speed (505) or 11-speed (705) internal epicyclic rear hub. It is believed to be compatible with other Di2 ETube components but this has not been verified.

Display / Wireless Communication:

SM-EWW01 ANT Wireless Broadcast Module: This module wirelessly broadcasts Di2 data (front and rear gear selection details, gear ratio, battery life) to a cycling computer using the ANT protocol. It is compatible with Dura-Ace 9070, Ultegra 6870 Di2 and Ultegra 6770 E-tube road shifting systems. SM-EWW01 plugs into the E-tube wiring system between existing components. It has an 2 wiring ports, so it can be connected between a front shifter and the Front Junction A, or at the rear derailleur (between rear derailleur and Etube wire.) It transmits through a proprietary private ANT wireless protocol, which may eventually become a standard public ANT+ protocol. It is powered by the same Di2 system battery. It is currently compatible with the Garmin Edge 1000, Mio 505, and the PRO SCIO cycling computers (with more to come.) The hidden buttons under the hoods of the 9070 shifter levers will switch screens on the cycling computer when paired with this module. It does not currently allow for shifting control from a cycling computer/device and it is not clear that this functionality will ever be offered. The SM-EWW01 is 38mm long, 25mm wide, 12.5mm high, and weighs less than 5 grams. It does not come with any wires; 1 wire would have to be added if adding this module to an existing Di2 system.

EW-WU101 and EW-WU111 ANT and Bluetooth Wireless Broadcast Modules: These modules are similar to the SM-WEE01 but also include Bluetooth capabilities in addition to ANT capabilities. They require the BT-DN110 battery or the BM-DN100 Battery Mount and cannot be used with the SM-EW67 Front A Junction.

SC705 Alfine Display Unit: This unit displays the battery level and the rear derailleur gear selection. It is powered by the system battery and has a port for the SM-BCR2 internal battery charger / USB diagnostic tool. It is primarily designed for Alfine systems (both 8 505-series and 11 speed 705-series). It is compatible with Ultegra and Dura-Ace Di2.

MT800 Digital Display with Bluetooth: Primarily aimed at XT mountain bike applications, this display allows toggling between the 3 synchronized shift modes (where both derailleurs are intelligently coordinated in unison by one pair of buttons, so no need for discrete shifting of the front derailleur.) It also shows battery level, gear position, shift mode and FOX iRD suspension position. The Digital Display required the new BT-DN110 battery. Existing Di2 XT systems are upgradable to be compatible with the new digital display after battery upgrade and firmware upgrade. This display has 3-port Di2 Cable junction and charging port integrated into the back and serves as a Front A Junction.

Batteries and Battery Mounts:

The batteries contain the main controllers for the system. It is therefore required to upgrade the battery to get features released in new versions of Di2 (such as Synchronized Shifting that automatically controls the front derailleur based on rear derailleur shifting.)

SM-BTR1 External Battery: This external battery must be used with the SM-BMR1 battery mount. It is removed from the mount and charged using a dedicated charger.

SM-BMR1 and SM-BMR2 External Battery Mount: This mount attached to bottle cage mount points or other dedicated frame mounts. It is available in 3 different mount lengths: -I (intermediate length), -S (short length), -L (long length). The SM-BMR2 is an updated version of the SM-BMR1.

SM-BTR2 Internal Battery: This battery is typically mounted in the seat post or seat tube of the frame. It is charged by plugging the SM-BCR2 Charging Cable/PC Adapter into the SM-EW90-A or SM-EW90-B Front A junctions.

BT-DN110 Internal Battery: This battery is required for Bluetooth wireless units and road groupset Synchronized Shifting functionality.

BM-DN100 External Battery Mount: This battery is required for Bluetooth wireless units and road groupset Synchronized Shifting functionality.

Front A Junctions:

SM-EW67-A-E Ultegra 3-Cable Junction: This is the original front junction with 2 integrated cables to connect to the dual control brake lever/shifters. The male cable ends on this Front A Junction will not mate directly to the male cable ends on any of the Time Trial/Triathlon dual control brake shift levers or shifters; SM-JC41 Rear B Junctions can be used to connect this front A junction to TT/Triathlon shifters. This Junction works only with External Batteries, not Internal Batteries.

SM-EW90-A Dura-Ace 3-Port Junction: This front “A” junction is most commonly used in road bike setups. 2 ports connect to the dual control brake / shift levers; the third port is for the cable that leads to the bottom bracket junction.

SM-EW90-B Dura-Ace 5-Port Junction: This front “A” junction is primarily used in the Time Trial / Triathlon setups. 2 of the port are for the brake/shifter dual control levers, 2 of the ports are for the aer0 bar bar-end shifters, and the 5th port is for the cable that runs to the bottom bracket (where the B junction joins the wires from the front A junction, front derailleur, rear derailleur, and battery.)

EW-RS910 Internal Bar-end Junction: This junction is installed into the end of a bar or in a dedicated frame port. It facilitates internal cable routing.

B Junctions:

SM-JC41 Internal Junction: This version has the exact functionality as the SM-JC40 external version, but doesn’t have the mounting tab for being bolted to the bottom bracket or wrapping the extra cable lengths. It has 2 ports on one end and 2 on the other, making it more compact. In addition to being located at the bottom bracket to connect the A junction, battery, front derailleur, and rear derailleur, it can be used at the handle bars to join multiple shifters prior to being connected to the A Junction.

SM-JC40 External Junction: This version is intended to be attached to the frame using the bolt that is commonly located underneath the bottom bracket housing. This junction contains no electronics; it’s sole purpose is to join 4 connectors together, which are usually the wire from the front A junction, the battery, the front derailleur, and the rear derailleur. There are wire holders above the housing to capture the extra wire length by wrapping it back-and-forth.

Cables, Grommets, and Cable Remove/Install Tool:

EW-SD50 Cables: These cables connect the front A junction, the battery, the front derailleur, and the rear derailleur to the rear B junction, which is typically located near the bottom bracket (near the cranks.) These are available in lengths of 300mm, 350mm, 400mm, 500mm, 550mm, 600mm, 700mm, 750mm, 950mm, 1000mm, 1200mm, 1400mm.

SM-GM01 Grommet: These round grommets are used when drilling round holes for internal cable routing, or with existing round holes. The required hole diameter is 6mm (6mm = .236 inches. Use a 7/32-inch drill bit and then “wallow-out” the hole to make it a little bigger; a 1/4-inch drill bit will work but is just slightly larger than necessary.)

SM-GM02 Grommet: These 7mm x 8mm oval shape grommets are used in some situations / frame designs.

Shimano TL-EW02 Ultegra DI2 E-Tube Tool: This tool is used to connect and disconnect the Etube wires. They are extremely difficult to connect/disconnect by hand, and pliers or other tools can damage the wires. Don’t get this confused with the TL-EW01 tool, which is for the older 5-wire 7970 cables. (My Dura-Ace TT Dual Control Levers came with one of these tools, but no other components did.)

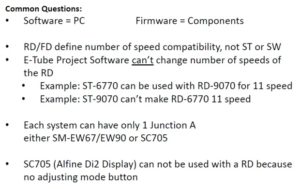

Common Questions (via Shimano):

Note: it is not necessary to replace the FD from upgrading from 10-speed to 11-speed.

What Components do I need to put together my own Di2 system?

Because of the huge number and variety of components, it’s very difficult to figure out what is actually necessary and what is optional. So here is a list, for the setup I recommend: Ultegra 6870. It starts from the handlebars and works backwards. (This assumes both front and rear derailleurs, but you actually don’t have to have both; you can pick one or the other and only the corresponding front shifter to go along with it.)

- Any Type of Shifters / Shift Buttons. The Dual Control Brake Levers/Shifters are not required. You can get the just the climbing shifters or Triathlon/TT bar-end shifters, and then potentially add the Dual Control Levers/Shifters at a later point. (The only exception is the Sprint shifters, which require specific Dual Control Levers/Shifters with special ports as noted elsewhere in this article.) Amazon.com link

- EW-SD50 Wires 1 and 2 between the front shifters and the Front Junction A (0nly for some shifters). This is a bit confusing, because some of the front shifters come with wiring attached to them and some of them require purchasing separate wires. In general, most of the stand-alone shifters come with wiring, as do the TT/Triathlon dual control shifters/levers, but the road dual control levers do not. Amazon.com link

- Front Junction A. I recommend the SM-EW90-B 5-port front junction A as it provides the most upgrade flexibility; get the 3-port option only if you’re positive you’re never going to add more shifting components. The older SM-EW67-A-E has 2 wires built-in to connect with each of the dual control shift/brake levers; it doesn’t offer much flexibility or compatibility with a TT/Triathlon setup or adding additional shifters. Amazon.com link

- EW-SD50 Wire 3 between the Front Junction A and the 4-port Rear Junction B connector. Amazon.com link

- EW-SD50 Wire 4 between the Rear Junction B and the Front Derailleur. Amazon.com link

- EW-SD50 Wire 5 between the Rear Junction B and the Battery. Amazon.com link

- EW-SD50 Wire 6 between the Rear Junction B and the Rear Derailleur. Amazon.com link

- Rear Junction B: This is where the wire from the front of the bike is connected to 3 output wires leading to the front derailleur, rear derailleur, and battery. SM-JC40 is for external wiring, SM-JC41 is for internal. Amazon.com link

- Grommets for any place where the wire goes into the frame through a drilled hole. Amazon.com link

- Front Derailleur. I recommend the Ultegra FD-6870 for 11-speed builds or the FD-6770 for 10-speed builds. The Dura-Ace FD-9070 is pretty much identical, just slightly (41g) lighter and 11-speed only. (I do not recommend the Ultegra FD-6770 unless you have a 10-speed setup, because of firmware compatibility issues with 11-speed rear derailleurs. Also, it is an older design than the FD-6870, so it is larger and offers slightly less shifting force.) Amazon.com link

- Battery and Charger. Internal or external, depending on the build. If you have to skill/time/money-to-pay-someone to get everything internal, I highly recommend that option. The SM-BTR2 internal battery has more advanced integrated electronics and is better for firmware upgrades with the SM-BCR2 internal battery charger/PC tool. If you go with the SM-BTR1 external battery, you will need the SM-BMR1 external battery mount and SM-BCR1 external battery charger. Amazon.com link

- Rear Derailleur. I recommend the Ultegra RD-6870 for a new build if you have 11-speed compatible wheels with 11-speed sprockets, or the Ultegra RD-6770 if you have 10-speed wheels/sprockets. The system must be match front and rear derailleurs (both 6870 11-speed or both 6770 10-speed.) Amazon.com link

- TL-EW02 Etube Wire Remove/Install Tool: It takes quite a bit of force to snap the wires in/out. You may think you can get it seated properly with just your fingers, only to then have the wire come loose because it wasn’t fully seated. It’s a good idea to keep one in your saddle bag. Amazon.com link

What wire lengths do I need? This question is impossible to answer correctly, as it’s highly dependent on the frame size and configuration. What I recommend is running string between the component mounting locations to measure the lengths. Be sure to add some extra length, as I find that wires seem to come up short pretty frequently, even when “adding a little extra” to start with. Nothing is more frustrating that having a wire that is 25mm too short. I recommend ordering a few extra wires of multiple lengths and then returning the unneeded/unused wires. As noted above, the standard wire lengths are 300mm, 350mm, 400mm, 500mm, 550mm, 600mm, 700mm, 750mm, 950mm, 1000mm, 1200mm, 1400mm. Do not cut/splice these wires; the connectors on the end of the wires are very small in diameter to start with and you’ll end up with a splice that is larger and less waterproof than you started with.

Acknowledgements: Special thanks to Di2diy for his continued help in the comments. Check out his Ebay store for custom Di2 batteries, harnesses, and components.

Technical Details of the Di2 CANBUS protocol and signaling

Thanks to commenter Ghislain for the details: “I reversed engineered the signal going to the RD. Since I did not have a special tap connector, I could only look at the actual signals in open loop (RD wire disconnected) on the wire going to the RD using an oscilloscope. First, I found that shift up and down are multiplexed on the same wire. A shift down would generate a positive 100 msec clean 8 volt pulse (varies between 50 msec to 500 msec depending on how long you hold the shifter). On the same wire, a shift up would generate a series of 2 msec pulses that would last the same time of a shift down pulse. Therefore, the RD has enough intelligence to discriminate between the 2 types of pulses. When you hold the button on junction A, a 140 msec pulse is generated. But since my RD wire was disconnected, the RD would not go in adjust mode.”

Hi I have just upgraded my bike to Di2. I have ST 6870 shifters with fd6770 and rd6770 derailiures with an internal battery, but when I connect to my lap top with etube it won’t connect. It appears to be wanting to see st6770 shifters. Everything works fine riding I just wanted to program multi shift. Has anyone else come across this problem? Any suggestions?

I believe ST 6870 are 11 speed and you are trying to combine it to 10 SPD 6770 FD/RD which are not compatible. I went 6770 all the way including my shifters just to be sure. The only 11 speed item I have on my bike is a DURA ACE 11 speed crankset which I haven’t had any problems with.

The ST6870 shifters are compatible with 10 speed 6770 components. But the system needs to be updated.

Nice to know. I just didn’t want to risk it and putting $$ down and regretting it so I stayed with same models.

Do I need to update the firmware in my btr2 with a pce cable? As when I connect just the btr2 battery etube says it’s not compatible with etube but I am running the latest version of etube.

You can not connect the battery directly to the PCE1, without a EW90 detected it can not update.

Use your BCR2 to update the complete system.

I just want to confirm….I’m running 6770 components but 11spd shifters (6870), 3port junction A…everything works fine…i install a Pave climbing shifter running off the rear deraileur shifter (right) and get no response from it…..whats the problem?

you will need to update the firmware so it knows it has the remote… also be sure your plugged into the middle port

Which port is that. ….is it the junction port?

The remote should be plugged into the top or middle port of the shifter. The lower port on the shifter is for sprint shifters only. For updates if you are using the BCR2 it plugs into the junction charger port, if you are using the PCE1 plug it into any open shifter port.

how can i get the climbing shifter to work on a 6770 group?

Your system will need an etube update, than it can be programmed however you want it from within the etube project.

I’ve heard that the SW-R610 shifters can plug into the 5 port junction box. Is there an adaptor to do this, or is this just wrong? I will be using the R785 hydro levers and would really like to use some kind of thumb shifter like Campagnolo has on their Ergo shifters. Any ideas?

No adapter needed they just plug directaly in. If you need more open ports you can use a JC41 and a jumper and get 3 more ports.

Thanks for the quick reply. From above: “SW-R610 Dura-Ace Sprint Shifter: This is the only component using a unique wiring connector; it is only compatible with the ST-9070 Dura-Ace and Ultegra ST-6870 Road Dual Control Brake Levers/Shifters.” To me that sounds like they *only* work when plugged directly into the levers.

Sorry I did not look closely at your message I thought you were asking about the remote R600 climbing shifter. The sprint shifter can only be used in the lower port of 11 speed shifters.

No worries. I think the ones I saw were talking about that one too. Dang!

Looks like the way to do it is to solder sprinter switches to the climbing shifter. Inadvertently, that is the “adaptor” I mentioned.

That will not work if you just splice it to the cable, it will short out the entire system the first time you press the switch. I have hacked where a switch has been spliced to the board inside the switch, but that a very difficult hack and quite delicate. Any momentary switch in the system needs to have a chip to identify it to the network.

Thanks. I have a question for Carlton re the SM-BMR1 vs SM-BMR2?

But first some background.

I had an intermittent fault in my FD-6770 / RD-6770 Di2 system. Replaced every wire and junction box and it was still variable. I read a post where someone had the same fault symptoms and it turned out to be corrosion inside the battery mount. If I bumped the battery mount the di2 would stop working and if I bumped it again it started to work again. Well eventually the whole lot stopped working and the battery mount no longer could be seen by e-tube. I purchased a sm-bmr1 and fitted it and all was good. Anyway, I thought I would setup the RD-6770 via e-tube as I thought it sounded a little noisy. When I started e-tube it said there was an update and I said yes. Then after the update it said there were FW updates so I said yes. Well since then the rd and fd don’t work when plugged in together but work individually when one is removed. The only thing different from the original setup is that the battery mount which I ordered as SM-BMR1 says in e-tube that it is a SM-BMR2. Hence the question.

If you update a BMR1 with the current etube version it will work the same as a BMR2. It sounds like you are trying to run a 10 speed and 11 speed system, are both FD and RD 6770?

You can downgrade the software in any component of the DI2 system. It is fiddly, but it can be done. I reported on how to do it about 2 months ago in the comments and Carlton put it up in the main info section. I had to downgrade an internal battery I bought recently which had late firmware incompatible with my 6770 front junction and was successful in doing this. I don’t do software updates anymore past the 2.5 version and I downgrade an new components I buy to the 2.5 version. If you downgrade it may get you back going without having to buy any additional components.

yes both 6770 dr

Well can’t say what it could be. If you are using a PCE1 for the updates than you can do diagnostics, if you are using a BCR2 than you can’t.

Each individual component using PCE1 has no errors. as a complete bike scan only one dr shows up. and on a successive scan other dr shows up. but not together.

Try using a different port on the other shifter.

Seems simple to me if you don’t update it you can’t use it. Update it and than you can use it.

Your site has been very helpful. I have an older 6770 setup, and I have an intermittent shift problem which I’m 90% sure is in the wiring going to the EW67A junction box from my right (rear) shifter. Instead of replacing the 67A, can I buy 2 e-tubes and the SM-EW90-A? I should mention I own the PC updater box, so updating the firmware is something I can do.

Yes an EW90 can be used. However be sure you have a relief loop going to the shifters so the plug is not being pulled on and disconnect when pressure from your hands or of the levers rotate slightly.

This is how my 6770 setup started playing up. Thought it was the wiring as well. Try disconnecting the front dr. and see if the rear dr now works perfectly. Let me know how you go.

hi,

My old ultegra 10spd front mech broke (snapped cage). So I took the opportunity to try to switch to 11 speed partly because ‘why not’, and partly because I couldn’t find any old 10spd mechs to buy.

So after researching on the web it seemed that I needed to replace both front and rear mech with the 6870 versions

This I have done, just a simple unit switch of both mechs

All went very smoothly with the major snag that nothing is working!

If i hold either shifter in for a few secs the battery ok green light comes on. but holding down the button on the junction box that usually allows micro adjustment of the rear mech, or to remover the crash protection does absolutely nothing.

Any ideas?

You need to update the firmware.

I have an original 7970 Di2 Durace system on my Trek Speed Concept 9.0. The shifter for the front chain ring on the aerobar stopped working. I talked to one guy from Trek that was doing bike maintenance work at a recent Ironman event and he told me that the entire harness needed to be replaced and that they are no longer available. What options do I have at this point?

After isolating and identifying events leading up to sudden failure, I would perform a continuity test for bad/broken electrical flow. My experience w/Service & Repair – not limited to bikes: Few techies will admit they don’t know.

Try Crosslake for wiring replacements.

Do you have information on Crosslake – when I searched I found a store in Mn that specializes in Moutnain Bikes – nothing on Di2 for a time trial bike.

Crosslake sales is correct place. They sell road bikes. In search box on me page, type in Dura Ace. You should get (3) wring choices.

http://www.crosslakesales.com/search?q=Dura+ace

The first thing you need to do is determine if it’s the shifter for the harness. Unplug the working shifter (R) and plug it into the (L) shifter and see if it shifts the FD, if not, than its the (L) shifter, if it does shift than its the harness. Also if both the extension and the bullhorn shifters are not shifting than its likly the harness. I have a harness on ebay I’m selling for $210 new in box. It’s a SM-EW79A-I for 7970 TT setups. Let me know, and I can get it to you through PayPal. If it’s the shifter look on ebay, but you will likly need to buy a pair. The stuff mentioned at Crosslakes ate rear harnesses and not what you need, unless it’s the rear harness. My cell is 818-653-9526.

Thank you – I just dropped the bike off at my mechanic to trouble shoot. I am going to drop by and give him your suggestions on trouble shooting. If we can narrow it down then I can decide on what to buy. I am glad you told me about the Crosslakes items because I could not tell what they were. I am not having any problem with the rear derailleur.

There is a remote possibility that it could be in the rear harness since it also connects to the FD, but it’s remote. There would also be a way to check for that by plugging the RD cable into the FD, this would also check to see if it’s the FD. The front harnesses and plugs get a lot more wear and sweet since your hands are holding onto the bars.

My Bike shop cam back to me and said that the buttons are toast and that the only way to fix this is to replace the entire harness. This is the original Di2 so everything is hard wired together. What should I buy and where can I get the harness and button assembly?

So if its the shifter buttons not sure why they are saying you need to replace the harness as well, the only place I know of the get shifters is on ebay used, and I see none being sold separately you would need to buy a complete group, where are you located?

Yesterday I went to PU the bike and we looked up the part number you recommended and observed that there is a plug in connection. We took off the grip tape and it appears that the plug was not connected. We did not have time to reconnect but I think that is the problem. My mechanic and a mechanic from Trek had told me that it was one interconnected harness – no plug. Thanks for your help if this doesn’t work I will call you at the number you listed in an earlier response. I am in Orange County CA

Bill, I’m in the Pasadena area so if you need more help you could just drive up. Sounds like you need a good LBS. BTW the connectors should have shrink sleeve over them to prevent them from coming disconnected and dry.

I thought you were somewhere in So Cal based on the area code that you had for the phone number. I did see the shrink wrap tubing when we pulled the wire out yesterday. I am not sure why it came apart, but it did. I have rode in a lot of different conditions (rain, bumpy roads, etc.) Also, the wire is under the grip tape and so over time pulling on that grip tape could do it. I like my LBS but they have some limitations when it comes to the high end things. If he cannot get this to work then I will give you a call.

Carlton, thanks very much for this informative page. I’ve installed my own DI2 to my new Merckx San Remo road bike. It wouldn’t have been possible without your page. I have 10spd dura ace cassette & chain and my FD/RD are both Ultegra 6770 DI2. Internal etube cable routing with internal battery, My crankset is dura ace 11spd 53/39, Shifters are both dura ace 9070 with sprint Shifters and climbing Shifters. Everything works flawlessly. Thanks again for your help!

Hi Di2diy, Please can you advise if it would be possible to programe a SW-R600 climbing shifter to operate the front derraileur, im a left arm amputee looking into my best options into working the front chainring on my Ultegra Di2 setup. I have heard it would be possible using the e-tube program

The R600 climbing switch can be configured to operate the FD with Up-Shift and Down-Shift activation as it does the RD.

All things being equal, it is a relatively simple job.

Hope this helps.

Yes it’s an easy reprogramming. When plugged into a PCE1 programmer, or through the junction A using the BCR2 there is a menu for setting the button options in the etube project setup.

Hello running di2 hydraulic shifters with 6770 front and rear deraulier, for some reason the shifters have stopped working , when the button on the 3 port junction box is pressed it will run through crash mode .

Be sure the cables are plugged in completely with a click, also be sure to leave a loop so the can’t come unplugged if the shifter moves.

I am using a Garmin Edge 520 Bike GPS. Adding a Wireless Transmitter SM‑EWW01 and updated all component firmware with E-tube Project I can now display Gears, Gear Combo, and Gear Ratio. While Gears are correctly displayed, Gear Combo and Gear Ratio are based on incorrect gearing information. Where within E-tube Project can I correct this information?

You update gear details in the Garmin Edge setup, not on the Shimano side.

Have Ultegra Di2 and was happily charging via USB with laptop running Windows 8.1. I upgraded the laptop to Windows 10 and now charging via USB not happening. Charging seems to start with orange light coming on, but then goes out after about 5 secs. I googled for solutions but have come up with nothing. I don’t have E-tube Project installed. Any solutions?

Charge using a USB charger like an iPhone not the computer.

The Dura Ace STI shifters 9070 are equipped with small buttons on top of each shifter, for controlling Garmin thru SM-EWW01 Ant+.

I was wondering if it is possible to retrofit the Ultegra STI 6870 shifter, with push buttons so they can do the same.

If the push buttons communicate thru CAN BUS or they have their own Ant+ transmitter, I guess it will be very difficult.

But have anyone investigating in the push buttons ?

The buttons cause commands to be sent over CAN to the ANT module. The switches and firmware for the commands are native to the dura-ace shifters and can’t be easily reproduced in Ultegra shifters.

I see, thanks.

Really love this site, a lot of really helpful and interesting informations. Thanks again.

Hello having problems with di2 hydraulic shifters, they don’t work all connections have been checked, there is power to junction box A and the rear derailleur will go through crash test mode but nothing happens when you use the shifters. Have even changed the cable from shifters to junction box A but the shifters still don’t work thanks

Have you updated the firmware? If not you will need to do so.

Primarily a cassette change . I have a di2 10 speed with a 11-25 cassette and want to change it to a 12-30 cassette . Is this just a straight swap and do I really need a medium cage to ensure this happens (chain will probably have to be changed)?

They don’t recommend a 30 with a short cage, but by adjusting the spacer screw you would probably have enough room, the real question is why? If you must wimp out then an 11 – 28 and a bit of Rule #5 should be sufficient even unto Ventoux 🙂

Hi Guys, this seems by far the most knowledgeable place on the internet for Di2!

I’ve just built up a new frame with my old (10spd Ultegra 6770) groupset. Connected everything and it all worked perfectly, set it up the indexing and was surprised how easy it all was. I then took the bike for a quick shake down (literally 3 minutes) and had no front shifting. I assumed this was the battery. CHarged it and still no front shifting. Plugged it into the computer and there are a few oddities.

1. Plugged into the left shifter, nothing else shows up (plugged into the junction box, both shifters show).

2. The battery doesn’t seem to show up at all.

Now, after going through and checking everything, I have no power at all!

Everything was already on the latest firmware.

I assume this is an issue with the battery mount, but find it hard to believe this has failed suddenly now.

Any ideas? (I broke my previous frame, so money is tight and i’d rather not spend more!)

Hi Robert,

Step – 1, Double-check the firmware is all up-to-date and that your connections are snug.

Step – 2, Report back with the good news.

Enjoy Di2.

First I assume everything is 6770 and no mixing of FD/RD 6870. Also it sounds like you are using a PCE1 for the updates (?) if so you can update each component separately with the option on the right in the main menu, so check each component. But first check the plugs going to the lever and be sure you are using the plug tool, and hear a “click” when you plug it in.

Yep, all 6770 and PCE1 for updates and error checking.

Haven’t had a chance today, but will double check everything independently. Yesterday, the battery wouldn’t show at all on the PC even when I plugged it in directly.

Robert, under normal thinking I agree with you that the battery housing should not fil as quickly as than, but I have had two of them fail in quick succession. I was thinking when it does it again changing to internal battery – I have already changed to 3 port type A junction and the leads to the shifters

Hi Malcolm, I was actually considering that… However, the cost is very high. At the cheapest online prices, it means £85 for the battery, £65 for the junction box (and most ridiculously!) £60 for what is essentially a USB charger! That’s £210 for basically an internal battery.

Even though i’d much rather have the internal battery.

Is there a way to be certain that it has indeed failed?

the way I found out is that when you insert battery and press the button in middle of junction (the one for the micro shift) you get the red light flashing when gear selector pressed, then when you take it out of that mode no shift at all. I know what you mean about the cost. I was fortunate in that I already had the USB box with my other bike with DI2.

I sell a seat post battery kit that will allow you to use your current wiring setup includes inline charger for $200. I have sold over 100.

http://www.ebay.com/itm/291752577324?ssPageName=STRK:MESELX:IT&_trksid=p3984.m1555.l2649

So, i’ve checked all the connections and everything is plugged in as it should be.

I then put the battery on charge again.

Battery back on bike – Green light flash on the junction box.

Still won’t shift the front mech

Plug the battery into the laptop – No errors

Plug the wire back into the battery and now nothing again. At all.

Back into laptop – it still says no errors.

To me, this seems to suggest that battery is only holding enough charge to operate the rear mech, and even then only for 5 minutes. Is it normal to fail so suddenly?

Seems odd that it has failed at the same time as I swapped the groupset onto a new frame!?

Is there any way to check the battery is knackered before I spend loads on a replacement to find that the battery mount is faulty?

On the computer does it actually show you have a battery installed? As when my battery housing have failed I can plug it in and update the firmware on those components the system saw, but it did not recognise a battery it said something like select from one of the above…

Yes, it shows the battery there and that there are no errors.

Rob.

Try unplugging the front DR and see if your Rear DR now works. If the Rear DR works, unplug it and plug the front Dr back in and see if it works. If so you have the same fault that my 6770 Di2 system developed.

I have upgraded to an 11 speed system at a large expense using current shifters, battery, mount, but new cassette, chain and crankset and have sent the 10 speed front and rear DRs to Shimano for their techs to check.

Hi Peter,

Thanks that sounds interesting and may explain my issues. I’ll try that and report back.

With the front DR unplugged, the rear works fine. Nothing on the front with the rear plugged or unplugged.

Now, does this mean there’s an issue with the front DR or, the left shifter? (or something else?)

I have tried re-programming the shifter buttons, so the left works the rear (nothing). Switching back to the right and it works again.

The left shifter doesn’t show when I plug it into the laptop via junction box, but shows (and has no errors when I plug it into the laptop) when it’s plugged directly into the shifter.

I think I will have to unwrap the (freshly wrapped – grrr) bars and swap the wires around to see try and establish if it’s the wire/junction box or the shifter.

Any other ideas would be much appreciated!

Rob, are you using the PCE1 interface to E-Tube. If so plug one connector into your left shifter’s second Di2 port or where ever you plug into to read your bike settings. Then plug the second PCE1 cable into the front DR.

If the FD shows up and tests OK it is a probable fault with the shifter.

But I think the problem is an issue with the FD. I will know more after I get more info from Shimano when they get around to look at my DRs that I have sent them.

Thanks for everyone for the help. I have now solved the problem… One of the wires (to the shifter) was knackered. Swapped the wires around and the left shifter worked fine. It took me a little longer than it should have to diagnose as that was part of the bike that I hadn’t touched at all moving the bits over (I just kept the bar/stem/shifters as they were when moving over to the new frame).

I will shortly rebuild the cockpit of my tri-bike. I am keen to have a clean front end for my aerobar set up.

I have been considering how best to use the new bar-end junction box (announced by Shimano in June). It can’t be used at the end of the bullhorn bars – the shifters will be there.

Could it be possible to position the bar-end junction box at the (rider) end of one of the aerobar extensions? The new bar-end junction box has only two ports, so how would it be possible to link both the TT (aerobar) shifters with both the bullhorn STI shifters? Do all 4 shifters need to be plugged directly into Junction A? Would a Y Junction somehow help?

What about the 5 port A junction?

It’s hard to fit the 5 port junction in an aero stem and still have it easily accessible for charging. I am hoping the new bar-end junction provides new options.

Or perhaps something will turn up at Eurobike.

not only do the shifters NOT need to be plugged into the junction A, but there only needs to be one cable plugged into the junction A so it can be put anywhere like under the seat post. all you need is a couple of JC41 and 1 short cable to plug them together and that will give you six ports out. that way you can have just one wire going to the cockpit from the rear of the bike. The JC41 are small enough to fit in most bars, but some drilling will be required for one wire to exit to the rear.

Now i’ve established my issue, i’ll be replacing the 10-speed junction box with the more up to date EW-90 junction box.

So, now that I have two defunct, one-ended etube cables. Can I attach one to a USB cable and charge the battery via the etube socket on the junction box?

Seems it could be a better option than buying the £70 shimano charger to charge an internal battery.

You can only charge the BTR2 with a BCR2 charger with the EW90. But if you had the internal BTR2 with a EW67 how did you charge it before?

I have the external battery. I’d like to move to either the internal shimano one or make my own. I just can’t get over the cost of the charger.

So you can’t charge through en etube port?

Well not with the Shimano battery, but I sell a kit on ebay that you can comes complete with charger. It’s really intended to be used with the EW67, without replacing the cables. So you could use the one you have even if one of the plugs has gone bad. The Shimano charger is also a etube interface, but if you already have a PCE1 its of no use.

Hello. Any indication if the new Dura Ace junction box EW-RS910 “bar end style” can be used together with Ultegra DI2 6870 group.

It could be a nice way to “hide” the box.

Hello, trying to get a new bike with DI2 ultegra. How can you tell the shop is not using the old version ?

If its 11 speed Ultegra then it will be the newer 68xx series Ultegra, it will use an internal battery, will have an SW EW90A or B front junction box with charger port and you could always ask them! If they lie take it back 🙂

Internal batteries are not the only option used for Ultegra 11 speed Di2, 6870. Many bikes come with external batteries as well. Also Ultegra 10 speed Di2 6770, could come with an internal battery, and have a EW90. Just be sure it’s 11 speed and not 10 speed.

I got knocked over by a car yesterday and now my rear mech goes past the first cog and forces the chain against the plastic spoke protector,the mech doesn’t look bent, do you think going through the setup will get it back to normal

Neil, your mech hanger is most definitely bent, albeit only by a small amount. You will need to have it realigned at your lbs or invest in an alignment tool yourself. They are a life saver and worth every penny.

Thanks for the advice Jeff, i replaced the hanger (only £10) the changes are smooth as silk again i didn’t have to go through setup. I’ve straightened the old one enough to keep as a spare

Good to hear you are back on the road again Neil. I personally always like to double check alignment with a tool after replacing a new hanger as I have come across a few in the past that still needed a small nudge to get perfect gear changes. This would also apply especially to aluminium bikes where the derailleur has had a knock and the frame drop out may have bent a bit. With a carbon frame tho you should be pretty safe with the correct alignment of a new hanger as has happened with yourself.

Happy cycling!

Hi all, maybe a rare failure but my 6870-FD actuator casting broke yesterday. No impacts, just snapped on an upshift. Unit just over 2 years old.

I only found one other example online (http://www.bicycles.net.au/forums/viewtopic.php?t=89140) which is identical problem to mine.

Anyone else come across this?

My 6870 is going on into two years as well. No breakage problems yet.

btw:

1. I owned a Vermont Castings wood stove over a period of 3 decades. During that time the cast iron back cracked three times and was fixed at the Vermont factory. However, each time I trucked it in I got the “……..never heard of or seen such a defect before…..” routine drilled in my ears.

2. You might be able to have it welded back by a Jewelry repairer – should you opt not to press the warranty.

Di2diy,

First, let me say thank you for sharing your knowledge and skill with a everyone. I know it takes a lot of time to answer questions.

As for mine… I have Cannondale Super Six Evo with an Ultegra 11 spd setup with external battery. I just bought the bike from the original owner via eBay. Bike is a 2015, completely stock and un-modified, my first Di2. I noticed there was a little rub in some gears from the rear mech, so I used the adjustment mode to trim it out. All seemed fine on the stand. Hopped on the bike for a test ride and, when I made the shift to 1st gear, the chain hopped over the top cog, jammed the derailleur, and broke the hanger. Turns out the top limit screw was not set at all. I untangled the mess, and checked to make sure the rear derailleur wasn’t hurt. It still shifted up/down fine, and I noted no issues. I ran through the gears several times. Worked fine each time. I ordered a new hanger and waited a week for it to arrive. My battery was fully charged, and system working normally.

Got the new hanger on, installed the mech, and made sure the etube wire was fully seated. Snapped the battery in place, and nothing. No shift, from either mech, no system power. I thought, maybe the battery needed charging, so I put it on charge and left it for an hour or so. Came back, lights were off on the charger, so I figured it was fully charged and installed the battery. It shifted 3-4 times, then stopped working. Checked the battery with a meter….dead as hammer. 0 mv. Put it back on charger and, this time, watched the charger. Yellow light comes on, indicating charge, then red light starts flashing after about a minute, indicating a faulty battery. The battery wasn’t dropped, exposed to heat/cold, or anything like that. Working fine one minute, stone dead the next. I’ve had cordless drill batteries do the same thing. A common issue with Li-ion batteries, I suppose.

At any rate, I suspect I may simply have a bad battery. I ordered one, and am waiting for it to come in. I’m cautious, however, and don’t want to risk frying my new battery if there is an underlying issue.

Sorry to be so long winded, but wanted to give all pertinent info.

What do you think? Simply a bad battery, or something else.

Thanks, Mark

Mark, That is a great bike. You will enjoy it. It takes a bit of force to ‘break’ a hanger.

Just read over the feeds here and you can see that making doubly sure solves many an issue and saves a load of $s.

Step 1; Carefully recheck you connections.

Step 2; Update your firmware [instructions are in the feeds here].

Step 3; Enjoy a great bike.

We love Di2.

Thanks for the tips. I have already checked all connections. As I said, working fine one minute, then squat. Hoping it’s just a bad battery.

I don’t have the PC interface. If the new battery has firmware conflicts, I guess I’ll have to either see if my LBS can do it, or just bite the bullet and get my own. Probably a good idea to have one anyway.

Thanks

Mark, It does seem curious that the battery failed after the event. however there is not much else to do but replace the battery… if a volt meter showed no power than its likely toast. If you had a PCE1 system checker you could check the system for faults in the RD, but when you get the new battery check the voltage, plug it in and do a RD reset by holding down the button on the junction box A till the RD goes through the reset. if the RD wont go through the reset there may be a problem with the RD. let me know what you find when you get a battery. Often I reply to people and never hear the results of suggestions, and it helps me know/learn how to advise. BTW there in no firmware in the battery, and would not advise updating the system… if it was working don’t fix it, it could just cause a different problem.

Thank you so much for the info. I thought it odd that the battery would be anything more than a power source, but I coulda swore I read somewhere in the previous posts that the battery had a “brain”, as well as the mount, and all system components. If it’s just a dumb battery, it should just be a straight swap.

I agree…hate it when people don’t post follow ups to issues. I will definitely keep you posted. New battery is supposed to be here Monday, according to USPS tracking. Maybe it’ll get here sooner!

Hey gang,

A new battery solved the problem. I checked it when it arrived, and there was barely any voltage out of the box. Put it on the charger and watched it like a hawk….kept waiting for the red trouble light to start flashing. It charged as it should and, an hour later, the battery was fully charged and read 8.2V on the meter. Snapped it in and every thing worked fine. Even checked again the next day. All good!

So in the end, it was just a bad battery. Odd that it crapped out when it did, but at least it was an easy fix.

On a side note: I found batteries offered on fleabay for as much as $105! Even some people who were asking $50-60 for used ones. A little digging and I found a seller with brand new batteries for $24.95 with free shipping. At that price, I’m thinking about picking up another one for a spare.

Thanks for all the help.

Great stuff, Mark. Occam’s Razor wins again! Simple fix best fix.

Thanks for the heads up on sourcing cheap batteries.

Ride fast and stay safe!

We love Di2.

Hi all, looking for a little help if anyone can point me the right way. I’ve got an up-to-date 2016 6870 11-speed Di2 setup:

SM-BTR2 internal battery (3.0.10)

SM-EW90-A 3-port Junction A (2.2.0)

ST-6870_L and -R shifters (3.0.0)