Table of Contents:

- Intro

- Background Details on Audi R8 Frame Cracking and Reinforcement Plates

- How to Inspect for Frame Cracks

- Details of the Retrofit/Repair Process, Cost Estimates, and How to Request Good Will Policy Coverage from Audi North America

- Doing the Retrofit Yourself

- Links and References

Intro

I love the Audi R8. I think everything possible should be done to preserve these cars and prevent early examples from potentially experiencing a preventable failure. When I purchased an R8 manufactured in January 2010, I assumed it had the reinforcement plates installed at the factory due to misinformation floating around. I decided to inspect the front frame area after I had owned the car for a few months. It did not have the reinforcement plates. So I then went through the process of figuring out how to get my car retrofitted, mostly for my piece of mind, and was able to get the retrofit completed at no cost to me.

After reading stories from a few owners who purchased cars with front frame cracks, I decided to thoroughly document the inspection and retrofit process for the benefit of others. This should be part of any pre-purchase inspection for 2006-2010 Gen 1 R8, and I think all owners of early Gen 1 R8s should consider this retrofit as a preventative measure.

Background Details on Audi R8 Frame Cracking and Reinforcement Plates:

There is an issue with front suspension mount frame cracking with the early Gen 1 Audi R8. This affects all vehicles model years 2007, 2008, 2009, and almost every 2010. It can affects both V8 and V10 vehicle, manual and automatic R-tronic transmission vehicles, and coupe/spyder/convertible vehicles.

There are numerous misconceptions and incorrect details floating around, so let’s review the facts:

- This is not an extremely common problem. There were approximately 13,500 Audi R8s manufactured between MY2006 and the end of MY2010. The guestimate is that this failure has happened well less than 100 cars, which is well less than a 1% failure rate. However, this number will likely continue to rise over time as more vehicles accumulate more miles.

- Frame cracks do not only occur on vehicles that were in a collision or were abused. Multiple vehicles with frame cracks show no sign of front collision, wheel damage, or other suspension components. A severe front wheel collision will definitely cause immediate failure. But it can also be triggered by normal driving conditions (hard-hitting multiple pot holes and/or speed bumps over time.) The frame cracks occur because the front suspension frame is cast from a relatively low grade aluminum and the entire force from the front shock absorber is concentrated in a small area. The cracks occur from a combination of brittle fracture (high impact force, like hitting a pothole) and fatigue failure (repetitive normal suspension forces over time.)

- Audi did not start installing reinforcement plates on 23-November-2009; May 2010 is the likely “all clear” date when all cars were manufactured with plates installed.

- 23-November-2009 is the date when Audi released an internal memo summarizing the change to start adding reinforcement plates. However, the change in production did not occur at that time.

- Reinforcement plates were not installed on all cars until around May 2010.

- Some, but not all, March/April 2010 builds did receive the reinforcements. It’s been verified by owners on R8talk.com that vehicles manufactured as late as April 2010 did not have the plates installed, which is near the end of the production run for model year 2010.

- To summarize, almost all 2010 Audi R8s did not have the plates installed at the factory and you can’t tell definitively by manufacturing date.

- Installing the retrofit reinforcement plates on R8s with no existing frame cracking is not difficult or expensive, but a very experienced welder is mandatory. The plates themselves are only $40 each and fit in the palm of your hand. A every experienced welder who know how to TIG weld aluminum is required, because the “pot metal” front suspension frame a low-quality aluminum that is very difficult to weld. The majority of the work is removing the front wheels, front suspension, and windshield wiper assembly. Audi recommends also removing the dashboard to make sure nothing in the passenger compartment (on the inside side of the firewall) gets overheated from the welding or catches fire, but people have welded the plates without removing the dash and had no issues.

- You should do a Preventative Retrofit instead of waiting for a failure. Full frame realignment is required if the joint completely separates, and cost can be in the $30,000 range, vs. $4,000 for a preventative retrofit. Details are below.

- The reinforcement plates do solve the issue and prevent frame cracking. There have been no reported suspension frame cracks in any Audi R8 with the reinforcement plates installed (manufactured in or after May 2010.)

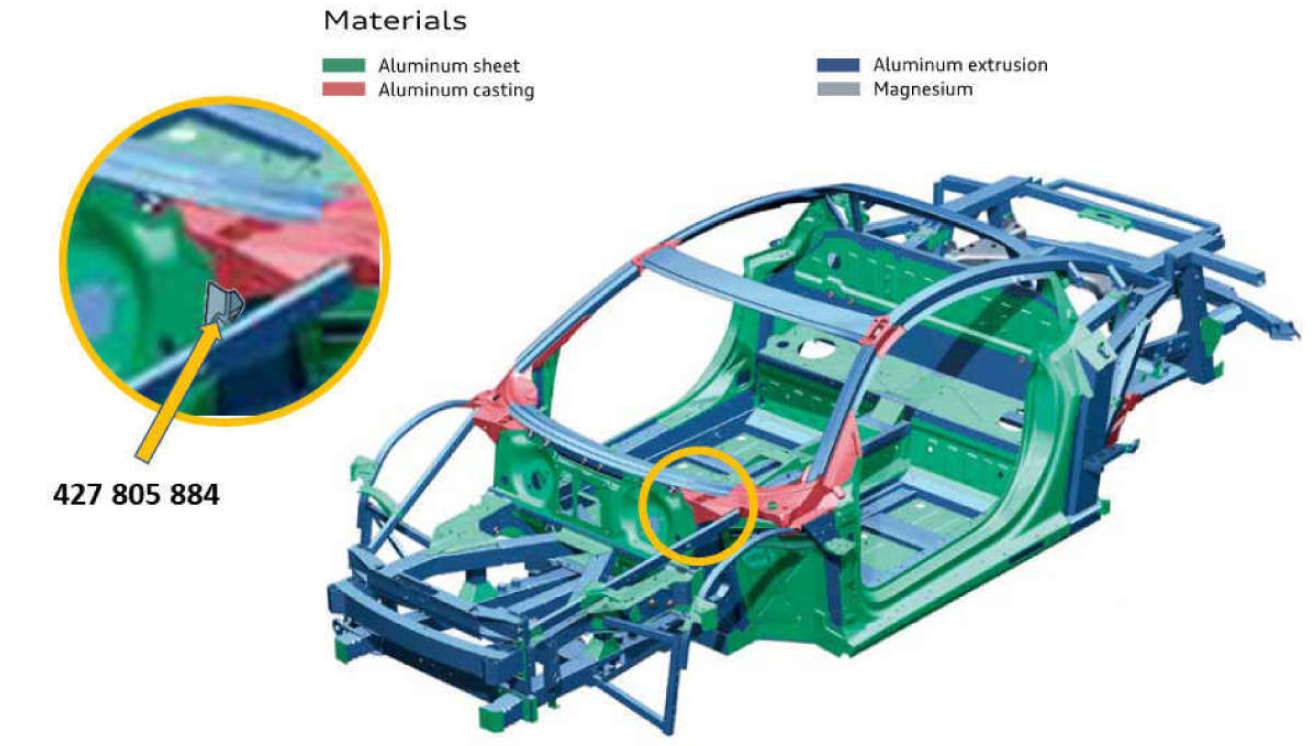

![Audi R8 Frame Reinforcement Plate. Thanks to R. N. Labas for supplying modified graphics.]()

![Audi R8 Aluminum Space Frame with Reinforcement Plate Installed. Thanks to R. N. Labas for supplying modified graphics.]()

- Epoxy-bonding the reinforcement plates to the frame is not as strong as welding them and there is no proof that epoxy bonding will prevent cracking. While a bonded plate is better than no reinforcement at all, it is not gong to be as strong as a welded joint. This joint was not designed for bonding adhesives. Bonded joints have to be specifically designed with forged or cast aluminum end components that have the torque moment connections designed into the connection itself. Then, at some distance away from the connection, a linear plane joint can be made with adhesives. The R8 joint in question was not designed in any way close to being suitable for a bonded joint. This joint was designed to be welded. The retrofit plates would need substantially greater rigidity, length, surface area, and manufacturing tolerances to have any chance of providing significant strength to this joint. Metal-to-metal epoxy bonding is very tricky as the forces are spread on all the surface and the epoxy thickness is critical, especially for shear forces. Also, bonding aluminum is very difficult as a thin oxide layer can prevent a proper metal contact.

- Audi has never officially acknowledge the problem. However, unofficially, multiple Audi techs who have gone through the R8 certification process have stated that they were told of the problem and how to inspect for it. Audi reportedly even had a cracked frame on display at a regional training center. This issue does not meet the guidelines for a NHTSA recall.

How to Inspect for Frame Cracks

- Remove the the plastic liners surrounding the front trunk:

- Put a support under the front hood to hold it in place when the struts are removed

- Left Panel Removal:

- Remove left hood support strut

- Remove left plastic trim panel

- Temporarily reinstall left hood support strut

- Right Trim Panel Removal:

- Remove Right hood support strut

- Remove Right plastic trim panel

- Temporarily reinstall right hood support strut

- Top Trim Panel Removal:

- Mark location of windshield wipers on front window using masking tape

- Remove wiper arms

- Remove top plastic trim panel

- Inspect the areas where the suspension mount towers meet the lateral cross brace

- The right side will be easy to inspect; there is no obstruction

- It is advised that the wiper motor assembly be removed to have full visual access to the left side suspension mount tower.

- Please note that the joints are covered in seam sealer. If the metal is cracked, the cracks will likely propagate through the seam sealer as well, but this is not guaranteed.

Here’s what you’re hoping NOT to find:

Details of the Retrofit/Repair Process, Cost Estimates, and How to Request Good Will Policy Coverage from Audi North America

It’s much better to have the brackets proactively installed, versus waiting until frame cracks are already present. If the cracks propagate completely through the frame member, there will be complete separation between, resulting in bending and structural misalignment that will be drastically more difficult to repair.

Step 1: Do NOT contact your local Audi Dealer. They know nothing of this problem and everyone will become more confused. There is no official documentation on this issue available to a dealer, and the retrofit procedures are not published in a system that is available to the dealer. The parts and procedures are only available to Audi Certified Collision Centers.

Step 2: Be patient. This is not going to be a standard process for anyone involved. It could take 3 months from beginning to end.

Step 3: Contact Your Nearest Audi Authorized Collision Center. You can find Audi-authorized repair facilities on this site: Audi Authorized Collision Repair Shop Locator https://www.audiusa.com/en/service/collision/. Call the collision and ask to speak to their most senior repair coordinator/advisor and give them all the details of what is in this document. Schedule a visit to the shop and talk to the repair coordinator. They will want some time to do some research on the issue. They will need to contact their Regional Training Organization (through Audi North America) to get the necessary details. Their regional (or national) collision trainer will likely be the best source of information. They will probably want to bring in the car and do an initial inspection to see if there is any existing cracking before creating the quote. I had to take it in twice total. The first time, they inspected the suspension mount area and took a lot of pictures; I had my car back a few hours later. About a month later, after Audi provided retrofit details and the parts were in, I took it in for the repair. That cost about $3400 and took about 1.5 weeks total. I’ve seen quotes as low as $2600 USD and as high as $8000 USD. The cost for my retrofit was $3400 USD and the breakdown for the retrofit is as follows:

Step 4: Send your request for Good Will Policy support to Audi Cars North America, knowing there is no guarantee of reimbursement. I waited until after my repair was completed before contacting Audi, but you can contact them if you have only a quote from an Authorized Audi Collision Center. Start at case by e-mailing [email protected] using the form letter below. It may take 3-4 several weeks to hear back from Audi North America (which was after the repair was already completed, and I’d already paid.) If you’re lucky, you’ll receive a call telling you that Audi will cover it. The call will be from Audi of America: +1 (800) 822-2834. If you’re very lucky, Audi will make a special approval of your request. Here’s the e-mail I sent to get the process started:

Dear Audi:

I’m the owner of a 20XX Audi R8 with the VIN of XXXXXXX. Unfortunately, my chassis was not equipped with the front suspension reinforcement braces that were added to all R8 chassis a few months after mine was produced.

I realize that there is no official recall issued by Audi to retrofit the reinforcement plates. However, it gives me a fair bit of anxiety when driving my R8 knowing that I could hit something on the road and potentially total my car due to a frame failure. I’ve therefore scheduled to have the reinforcement plates retrofitted by the local Audi Certified Collision Center (Name of Collision Center, address of collision center, phone number of collision center. Name of my repair coordinator at collision center.)

I was wondering if Audi North America would consider assisting with the cost of this retrofit. I realize that the frame reinforcement retrofit is not an official recall. But I also realize that it was subsequently identified as a design weakness in the frame that was quickly corrected in production. I know that aluminum is much more prone to high-cycle fatigue vs. steel, so it does concern me that the likelihood of failure will increase as miles and time accumulates on my car.

Please let me know if Audi North America would consider assisting with the cost of frame reinforcement retrofit on my 20XX R8.

Thank you,

My name

My address

My telephone numberMy vehicle details & VIN

Step 5: If Audi Takes Care of You, Be a Loyal Audi Customer and Spread the Word. If Audi covers the cost of the retrofit/repair under goodwill/policy, be a loyal Audi customer for life. If they don’t, don’t be angry, because you are not entitled to reimbursement. This issue, after all, does not meet the standards of a NHTSA recall. The fact that Audi would even consider reimbursement 10+ years after production is remarkable. There are no guarantees and it’s better to have the frame retrofitted than it is to worry about it potentially failing.

Doing the Retrofit Yourself

I recommend having an Audi-certified shop do this work following the Audi-provided procedure. This could help with the future value of the car. However, dealing with the unofficial Audi process can be very cumbersome and it can be easier to just take your car to an expert who knows how to do the repair. User @TriniTT on R8Talk.com has offered to coordinate the repairs for anyone in the US who is interested and has a solid reputation, and the cost will likely be lower than at an Audi Collision Center.

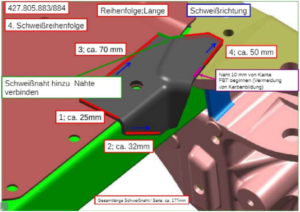

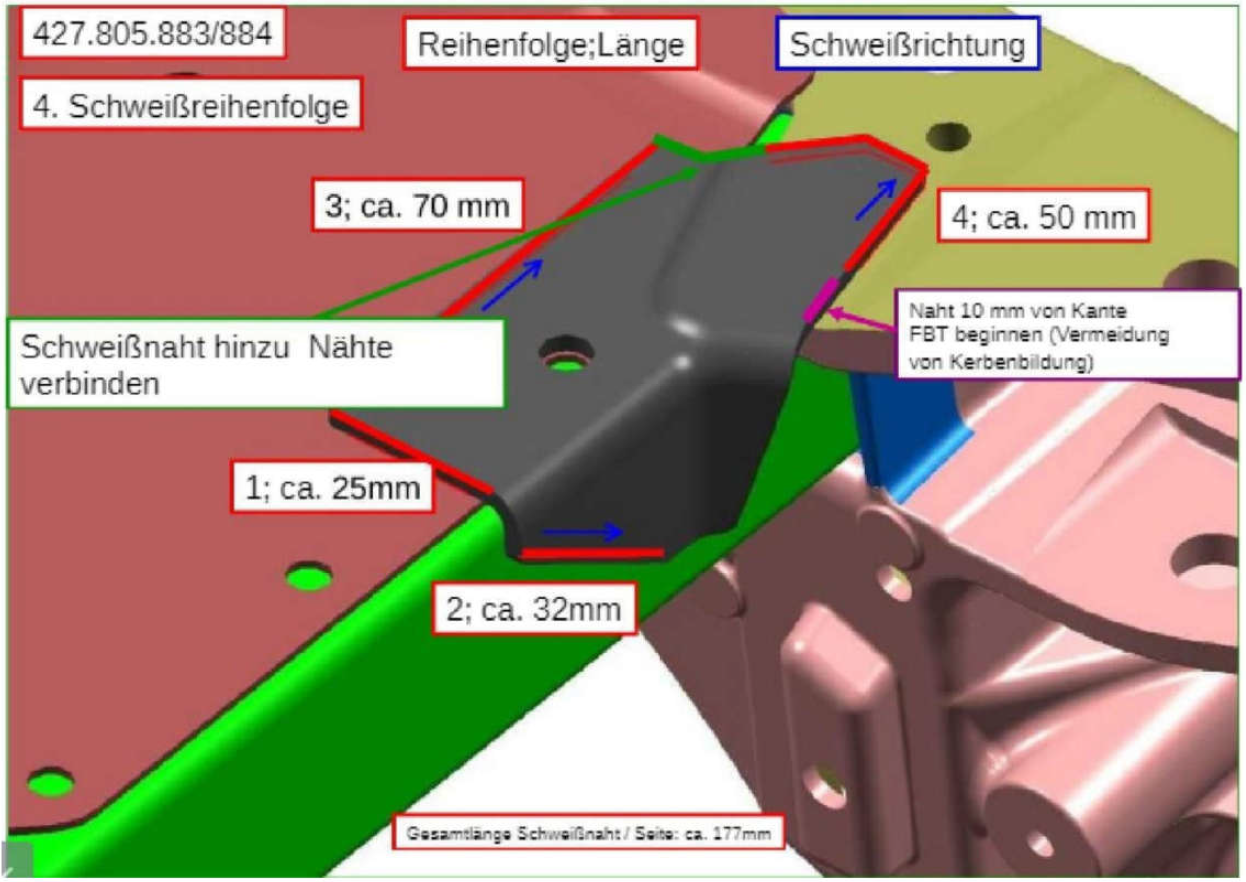

If you want to do the repair yourself, the reinforcement plates are available through Audi Dealer Parts Departments. However, they can be procured from seller VWdirect on ebay.co.uk or from @R8stuff on R8Talk.com. The part numbers are 427805883 and 427805884 and cost is only about $50 USD for both. The parts are stamped Al-Mg-Si, which indicates a much higher grade of metal than the casting on which they are welded. (Please note, if you want to receive policy support from Audi, you will probably need to use an official Audi Collision Center.)

If the welder doing the retrofit is not experienced, they can overheat the Audi Space Frame and weaken the factory welds, causing more damage. Make sure the welder is an aluminum specialist. There is quite a bit of diligence required for the material preparation and making sure the weld area is clean bare metal; this is far more important for aluminum than for steel. But if done correctly, then the welds will not affect the integrity of the surrounding material. Basically, issues can arise if the welder tries to run a continuous bead without controlling the material temperature.

There is an official Audi procedure, but it is only shared with Audi Collision Centers if/when Audi reviews/approves the repair. Audi has coordinated the retrofit for customers and provided documentation on how to do the work, but not to third parties. People have successfully conducted this repair by removing only the front wheels, suspension, and wiper assembly and have left the interior dash in place. This substantially reduces the cost and effort, but proceed with caution if taking this approach.

Links and References:

R8 Structural Reinforcement Retrofit Done!

https://www.r8talk.com/threads/r8-structural-reinforcement-retrofit-done.134578/

My R8 is Cursed

https://www.r8talk.com/threads/my-r8-is-cursed.177061/

SamCrac on YouTube: This repair method is strongly NOT RECOMMENDED!

Here’s Why My Cheap Audi R8 was TOTALED! Major Factory Flaw Made my R8 Salvage!:

https://www.youtube.com/watch?v=QOlvG1QbCDU

I Repaired My Totaled Audi R8’s Cracked Frame for $500! Insurance Quoted $29,522!:

https://www.youtube.com/watch?v=eIsW_oNLZjM

So how do you carry your bicycle on your Audi R8? I can put a bicycle inside a non-power seat 996 chassis 911.

Hey Michael,

The quick answer is that I just use a different car. It’s too much effort otherwise.

However, Audi does offer carriers that work with the R8. I’m not sure I’m completely convinced that the suction cups are 100% reliable, but numerous owners swear by them: https://parts.audiusa.com/accessories/Audi__R8/Bike-Rack.html